In the evolving landscape of lithium battery materials, performance and safety are paramount. Boehmite, a specialized alumina monohydrate, has emerged as a crucial coating material, significantly enhancing battery safety and performance. To produce the high-purity, consistently fine boehmite powders essential for uniform coatings, manufacturers often employ advanced powder processing technologies like jet mills to achieve the required precise particle size distribution. As a trusted provider of advanced powder processing solutions, Polvere epica Machinery offers equipment that meets these rigorous production demands.

1. Introduction to Boehmite

Boehmite, also known as soft aluminum trihydroxide with the molecular formula γ-AlOOH, is a major component of bauxite ore, alongside diaspore (primarily α-AlO(OH)). The German chemist Johann Böhm first identified this mineral in 1925. Later, in 1927, Draparante confirmed its presence through an analysis of bauxite from Les Baux-de-Provence. The mineral was subsequently named after this region.

2. Preparation Methods for Boehmite

Boehmite is a thermodynamically metastable phase that readily dehydrates at high temperatures. Multiple synthesis routes can produce it, such as acid, alkali, carbonization, alkoxide hydrolysis, organic complex hydrolysis, and hydrothermal methods. In coating applications, industrial-scale production uses chemical synthesis and prioritizes crystal transformation control. Achieving the fine, narrow particle size distributions needed for effective battery coatings, particularly as trends move towards smaller particles, often involves precise milling stages, where technologies like the mulino a getto provide excellent control over final product fineness and consistency.

1) Acid Method: This process precipitates γ-AlOOH from an aluminum salt solution using a base.

2) Alkali Method: This method uses an acid to precipitate γ-AlOOH from an aluminate solution.

3) Carbonization Method: A specific alkali method where CO2 is bubbled through a sodium aluminate solution.

4) Alkoxide Hydrolysis Method: Involves hydrolyzing an aluminum alkoxide in a solvent.

5) Organic Complex Hydrolysis: Entails forming a complex with an organic ligand before hydrolysis.

6) Hydrothermal Method: Uses a high-pressure, high-temperature aqueous environment to convert alumina precursors into high-purity, well-crystallized boehmite.

The boehmite used for coatings is produced via chemical synthesis, a process that centers on crystal transformation.

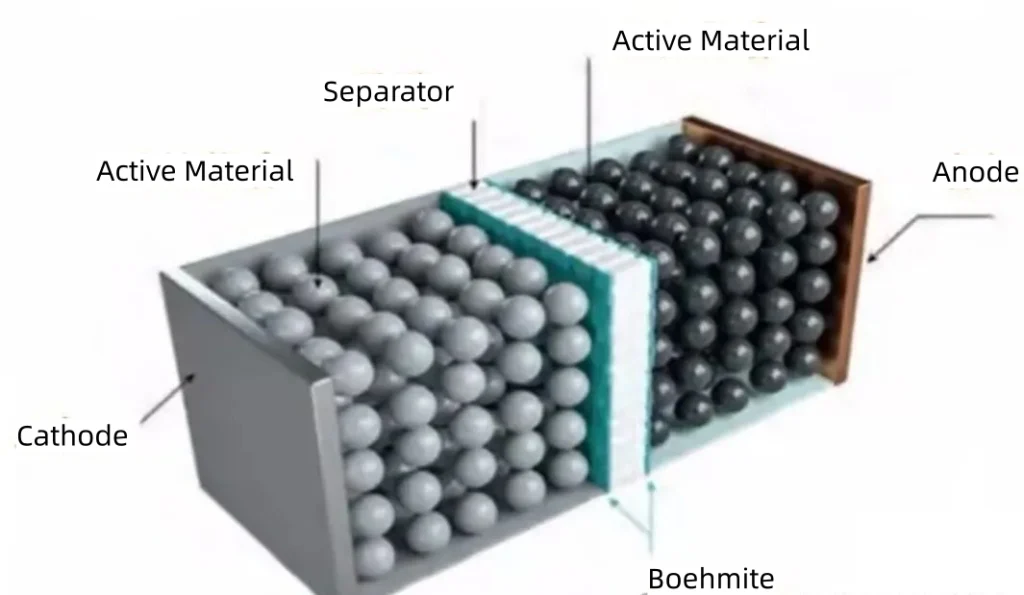

3. Application of Boehmite in Lithium Battery Separator Coating

Boehmite is primarily used for coating lithium battery separators and electrode sheets. As a separator coating, it enhances heat resistance, improves puncture strength, and boosts overall battery safety. On electrodes, it helps mitigate burrs from the cutting process, preventing internal short circuits. Furthermore, boehmite’s low magnetic impurity content, low water absorption, low specific gravity, and low Mohs hardness contribute to improved rate capability, cycle life, production yield, and reduced self-discharge. To ensure these coatings are perfectly uniform and effective, the raw boehmite powder must be of exceptionally high and consistent quality. Modern boehmite jet mills systems excel in this role. They are engineered to produce ultra-fine, narrow-distribution boehmite powders with minimal contamination. This capability is critical for forming uniform lithium-ion channels on the separator, which directly enhances battery performance and safety.

| Coating Material | Separator Coating Type | Key Product Characteristics | Primary Application Areas |

| Ceramic (Boehmite, Ultra-fine Alumina) | Inorganic Coating | Improves heat resistance and puncture strength of the separator; enhances battery rate capability and cycle performance; increases cell production yield; reduces self-discharge during battery use. | Power Lithium Batteries, Consumer Electronics Batteries |

| Ceramic + PVDF | Organic-Inorganic Hybrid Coating | High temperature resistance, reduced thermal shrinkage; improved adhesion and battery rigidity; enhanced electrolyte absorption; extended cycle life. | Consumer Electronics Batteries |

| PVDF, Aramid | Organic Coating | Improved adhesion and battery rigidity. Increases heat resistance and oxidation resistance of the separator. | Consumer Electronics Batteries |

Key advantages of boehmite in lithium battery separators include:

1. Plate-like structure creates channels for lithium ions without compromising air permeability.

2. Low magnetic impurity content increases cell yield and reduces self-discharge.

3. Excellent chemical and electrochemical stability, resisting electrolyte corrosion.

4. Narrow particle size distribution ensures uniform coating and consistent performance.

5. High purity enhances thermal and chemical stability.

6. Low hardness reduces abrasion on coating machinery.

7. Low specific gravity increases coverage area, reducing cost and weight while improving energy density.

4. Market Development of Boehmite

According to GGII data, global boehmite consumption reached 73,000 tons in 2024, with China accounting for 59,000 tons, a year-on-year increase of 31%. Key market trends include the shift towards smaller particle sizes and growing demand driven by increased battery production and higher coating penetration rates. GGII forecasts China’s lithium battery boehmite usage to reach 74,000 tons in 2025, with a projected CAGR exceeding 20% from 2024 to 2027.

Epic Powder Machinery: Your Partner in Advanced Material Processing

The production of high-performance materials like boehmite relies heavily on advanced powder processing technologies like jet mills. Epic Powder Machinery specializes in the research, development, and production of high-end grinding and classifying equipment. Our jet mill systems and air classifiers are engineered for high precision, efficiency, and reliability, making them ideal for producing the fine, consistent powders required in applications like lithium battery material coatings. By partnering with Macchinari per polveri epiche, companies can leverage advanced technology to optimize their product quality and maintain a competitive edge in the rapidly evolving new energy materials market.