Neodymium Iron Boron (NdFeB) permanent magnets, are third-generation rare-earth magnets that have been pivotal since their introduction in the 1980s. With their exceptional magnetic energy product, high remanence, and high coercivity, NdFeB magnets are indispensable in modern industry. Composed primarily of neodymium (Nd), iron (Fe), and boron (B), forming the tetragonal intermetallic compound Nd₂Fe₁₄B, these magnets offer outstanding magnetic performance and cost-effectiveness.

They have driven the miniaturization, lightweight design, and efficiency of electronic devices, finding wide applications in wind power generation, electric vehicles, consumer electronics, and medical equipment. Depending on production processes, NdFeB magnets are categorized into sintered, bonded, and hot-pressed types, each with distinct magnetic properties, production characteristics, and application domains.

Sintered NdFeB: High Performance with Complex Processing

Sintered NdFeB magnets are the most powerful, widely produced, and extensively used NdFeB magnets, boasting a maximum magnetic energy product (BH)max exceeding 50 MGOe, far surpassing other permanent magnets. Their production is a highly precise and complex process, integrating multidisciplinary engineering techniques.

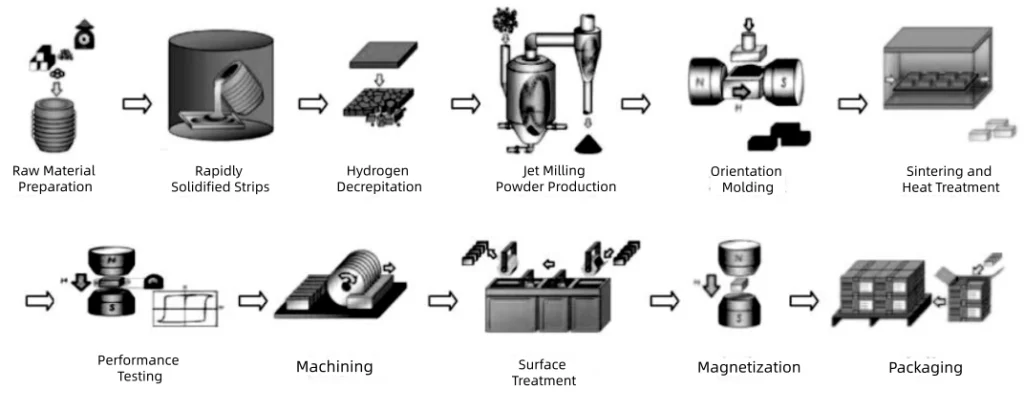

Production Process

Sintered NdFeB magnets are manufactured using a classic powder metallurgy process, with the following key steps:

1. Material Proportioning and Melting: The composition of Nd, Fe, B, and small amounts of additives (e.g., dysprosium, terbium, cobalt, or aluminum) is precisely calculated based on target magnet performance. These are melted at high temperatures in a vacuum or inert atmosphere induction furnace to form a uniform alloy melt, which is then rapidly cooled into alloy ingots via strip-casting.

2. Hydrogen Decrepitation and Milling: The alloy ingots are broken into smaller particles using Hydrogen Decrepitation (HD), followed by φρεζάρισμα με πίδακα to produce fine, uniform powders (typically 3-5

μm). Particle size distribution, morphology, and surface area significantly impact the final magnet performance.

3. Orientation, Pressing, and Sintering: The powder is pressed into shape under a magnetic field to align the particles’ easy magnetization axis, followed by cold isostatic pressing to increase green compact density. The compact is then sintered at 1000-1100

°C in a vacuum to densify the particles, forming the final sintered magnet.

The entire process requires strict environmental control, particularly oxygen levels, as neodymium oxidizes easily, severely affecting magnet performance.

Applications and Limitations

With their superior magnetic properties, sintered NdFeB magnets are used in high-performance applications such as:

Drive motors for electric vehicles

Wind turbine generators

Industrial servo motors

High-performance acoustic equipment

MRI medical devices

However, sintered NdFeB magnets have limitations:

Brittle and Hard: Poor machinability leads to cracking or damage during processing.

Temperature Sensitivity: Operating temperatures typically range from 80-250°C.

Corrosion Susceptibility: Highly prone to oxidation, requiring surface coatings.

Technical Challenges: Controlling grain growth and microstructure during sintering is critical and impacts final performance.

Bonded NdFeB: Precision and Complex Shape Advantages

Developed to address the machining challenges of sintered NdFeB, bonded NdFeB magnets emerged in the 1970s. These magnets are created by mixing magnetic powder with plastics or rubber and shaping them in a magnetic field.

Production Process and Characteristics

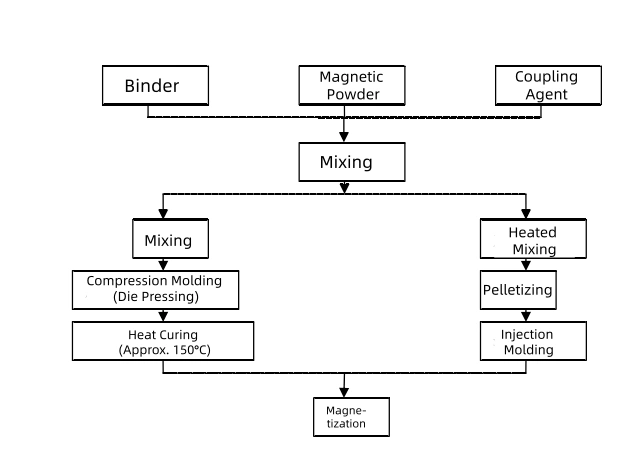

Bonded NdFeB magnets are made by combining NdFeB magnetic powder with binders like rubber or plastic, directly molded into various shapes based on user requirements. The key production steps include:

Magnetic Powder Preparation: Powders are produced using methods like HDDR (Hydrogenation-Disproportionation-Desorption-Recombination), mechanical crushing, or rapid quenching. HDDR is the dominant method, yielding high-coercivity powders with an average particle size of ~0.3 μm.

Molding Processes: Include calendering, injection molding, extrusion molding, and compression molding, with calendering and injection molding being the most common.

Bonded NdFeB magnets offer high dimensional precision, minimal deformation, and the flexibility to form complex shapes like strips, sheets, tubes, or rings, making them ideal for automated mass production. The inclusion of binders enhances mechanical strength and isotropy, allowing uniform magnetic properties in all directions and enabling multi-pole or infinite-pole magnet designs.

Performance, Applications, and Limitations

While bonded NdFeB magnets have lower magnetic performance than sintered ones, they offer superior consistency and stability. Key applications include:

Hard disk drive (HDD) magnets (a core application)

Office automation equipment (printer motors, scanner motors, copier synchronous motors)

Automotive micro-motors (EPS steering sensors, wiper motors, window motors)

Industrial and household motors (servo motors, power tool motors, air conditioning motors)

Φόντα:

High molding precision and ability to form complex shapes

Good mechanical strength

Lower cost due to reduced material waste and machining needs

Limitations:

Lower magnetic performance (50-70% of sintered NdFeB) due to non-magnetic binders

Limited temperature resistance, as binders may degrade at high temperatures

Surface protection may still be needed in harsh environments despite better corrosion resistance

Hot-Pressed NdFeB: A New Path Balancing Performance and Cost

Hot-pressed NdFeB magnets are the most technically complex and least industrialized of the three NdFeB magnet types, yet their unique properties make them irreplaceable in specific applications.

Production Process and Characteristics

Hot-pressed NdFeB magnets are manufactured using a thermal deformation process, which includes:

Loading rapidly quenched NdFeB magnetic powder into a mold.

Applying unidirectional or bidirectional pressure at high temperatures (typically 600-800°C).

Achieving densification and grain orientation.

Hot-pressed NdFeB magnets offer high density, excellent orientation, superior corrosion resistance, and high coercivity. Their magnetic performance, with a maximum energy product of 30-45 MGOe, lies between that of sintered and bonded NdFeB. The hot-pressing process yields a fine, uniform grain structure, with average grain sizes below 50 nm—much smaller than the 5-10μm grains in sintered NdFeB. This fine grain structure enhances coercivity while maintaining good remanence and magnetic energy product.

Applications and Development Challenges

Hot-pressed NdFeB magnets are primarily in automotive EPS (electric power steering) systems, high-performance micro-motors, and specialized sensors. However, their complex process and high production costs limit current output, preventing large-scale industrialization.

Key challenges include:

Process Complexity: Precise control of temperature, pressure, and deformation rate during hot pressing is critical.

High Equipment Costs: Hot-pressing equipment is expensive and requires significant investment.

Raw Material Costs: The cost of raw materials for hot-pressed NdFeB can exceed that of the finished product.

Despite these challenges, hot-pressed NdFeB holds potential for applications requiring high magnetic performance and complex shapes, offering a promising solution in niche markets.

Future Trends in NdFeB Magnets

As industries like electric vehicles, renewable energy, and smart manufacturing grow, NdFeB magnets face increasing demands. Future trends include:

Balancing High Performance and Low Cost

High Performance: To meet the needs of high-end applications, NdFeB magnets will evolve toward higher coercivity and operating temperatures through techniques like grain boundary diffusion, grain refinement, and alloy optimization.

Cost Reduction: Reducing reliance on heavy rare-earth elements by developing low-dysprosium or dysprosium-free formulations is a research focus.

Process Innovation and Structural Optimization

Emerging techniques such as dual-alloy methods, grain boundary diffusion, and nanocomposite magnets promise to enhance performance while lowering costs. Microstructural control, including optimizing grain boundary phase distribution and rare-earth-rich phase continuity, can significantly improve coercivity without sacrificing remanence.

With the rapid growth of electronics, electric vehicles, and energy-efficient technologies, NdFeB magnet applications will continue to expand. Over the next five years, demand is expected to grow by over 25% annually, with electric vehicle applications reaching tens of thousands of tons and industrial robotics exceeding 5,000 tons.

Green Manufacturing and Sustainability

The strategic value and environmental impact of rare-earth resources are increasingly critical. Developing green manufacturing technologies, improving material utilization, and promoting recycling will be key to the sustainable development of the NdFeB industry. Bonded NdFeB, with its high material efficiency and low processing waste, has a natural advantage in this regard.

συμπέρασμα

Sintered, bonded, and hot-pressed NdFeB magnets each offer unique performance characteristics and application domains, forming a complementary ecosystem. Sintered NdFeB dominates high-power, high-demand markets due to its superior magnetic properties. Bonded NdFeB excels in precision, complex shapes, and cost-effective mass production for miniaturized applications. Hot-pressed NdFeB, with its unique attributes, plays an irreplaceable role in specialized fields.

As electric vehicles, robotics, and renewable energy advance, NdFeB magnets will remain pivotal in driving technological progress and industrial development. Simultaneously, green manufacturing, efficient resource use, and sustainability will shape the industry’s future.

Μηχανήματα Epic Powder

Στο Μηχανήματα Epic Powder, we specialize in powder processing solutions, including advanced air pulverizers designed for producing high-quality NdFeB powder. Our air pulverizers ensure precise particle size control and uniform morphology, enabling the production of NdFeB powder optimized for sintered, bonded, and hot-pressed magnet applications. As a trusted leader in powder processing equipment, we are committed to providing tailored solutions to meet your unique requirements. Επικοινωνήστε μαζί μας today for a customized solution to enhance your NdFeB magnet production.