Jet mills play a crucial role in the powder processing industry, especially within sectors such as batteries, ceramics, and pharmaceuticals. These mills are widely used for ultrafine grinding and precise classification of materials. A fundamental aspect of achieving optimal performance in jet milling is understanding how gas velocity and pressure interact. This knowledge not only improves grinding efficiency but also helps control particle size distribution and enhances overall product quality.

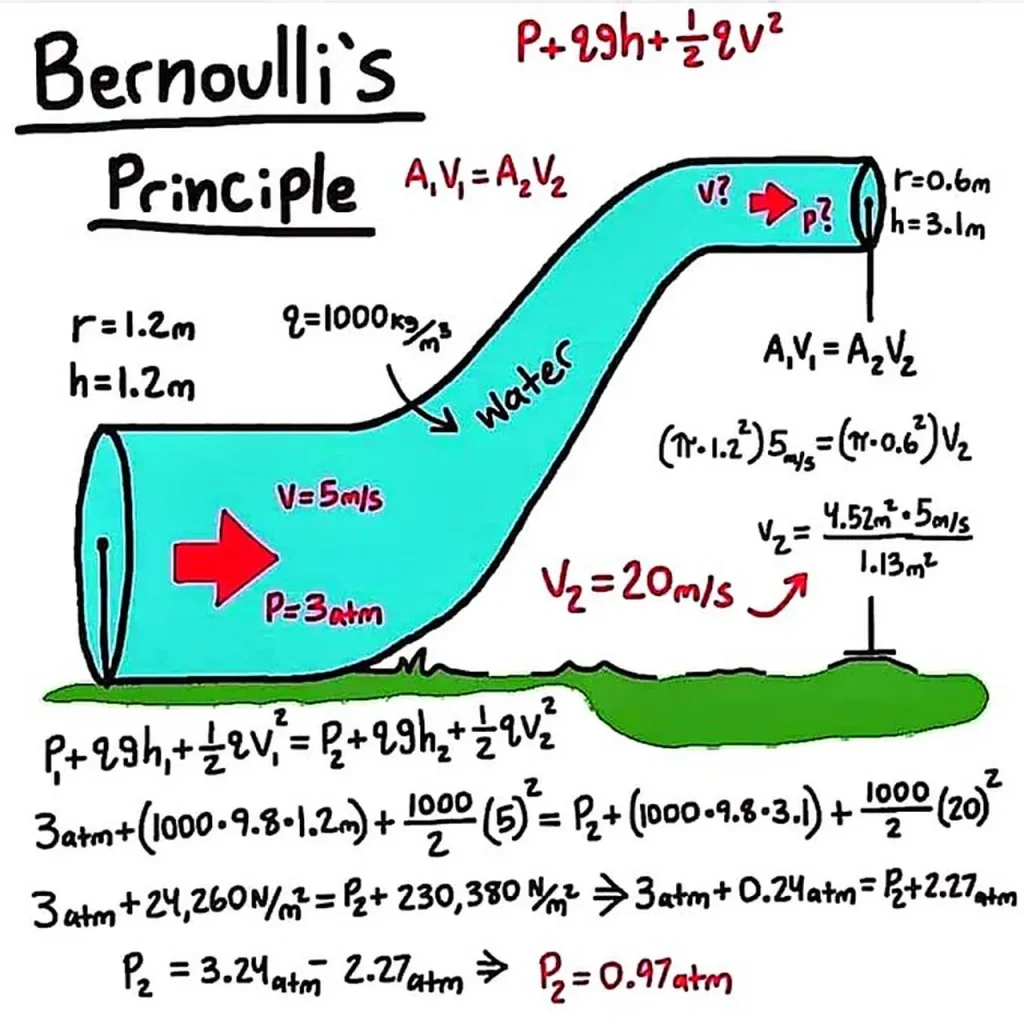

The Fundamental Physics: Bernoulli’s Principle

At the core of the jet mill’s operation is Bernoulli’s principle, which explains the inverse relationship between velocity and pressure in fluid dynamics. When gas flow velocity increases, the pressure decreases, and vice versa. Specifically, a higher gas velocity corresponds to increased kinetic energy within the fluid, which results in lower pressure. This pressure difference is vital in jet mills as it drives the movement and collision of particles, essential for effective grinding.

How Gas Velocity and Pressure Affect Jet Milling

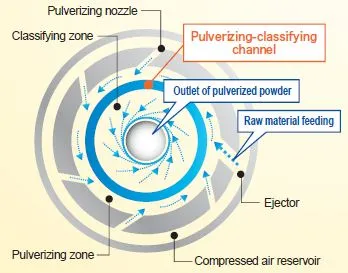

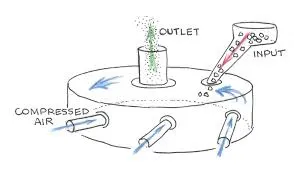

During the grinding phase, compressed gas is accelerated to supersonic speeds through a specially designed nozzle, often reaching velocities between 300 and 500 m/s. This rapid acceleration significantly increases the kinetic energy of the gas, allowing particles to collide with greater force, thereby facilitating efficient size reduction. At the nozzle’s outlet, the pressure drops due to the increase in velocity, creating a low-pressure zone that helps draw materials into the grinding chamber and prevents material from leaking out.

The classification stage leverages controlled velocity and pressure to separate particles based on size. Using a high-speed rotating turbine, centrifugal forces push coarser particles to the outer edges, returning them to the grinding zone for further processing. Meanwhile, finer particles travel with the gas stream toward cyclone separators for collection. Adjusting parameters such as fan suction and nozzle pressure allows precise control over gas velocity and pressure in the classification zone, enabling accurate particle size management.

Impact of Pressure and Temperature on Gas Flow

The pressure of the working gas is a dominant factor influencing gas velocity inside a jet mill. Higher pressures result in faster gas flows at the nozzle exit, for instance, steam pressures ranging from 0.8 to 1.7 MPa can produce velocities as high as 500 m/s. Elevated pressure not only increases speed but also raises gas density, which further boosts the kinetic energy available for particle breakage.

Temperature also plays a significant role. Higher gas temperatures can raise the critical velocity of the gas, improving the mill’s grinding capacity. For example, the velocity of air can increase from approximately 320 to 500 m/s when heated. However, the material’s heat resistance must be taken into account, especially for heat-sensitive substances or surface modifiers, requiring careful temperature regulation during milling.

Practical Example: Titanium Powder Milling

In an application involving titanium powder, superheated steam at temperatures between 300 and 400 degrees Celsius combined with steam pressure of 0.8 to 1.7 MPa generates a gas flow around 500 m/s. This environment produces intense particle collisions, achieving micron-level particle sizes. By fine-tuning pressure and velocity, operators can adjust the final particle size distribution within a range of 1 to 74 micrometers, tailored to specific material requirements.

Conclusion

In jet milling processes, a clear understanding of how gas velocity and pressure interact is fundamental. High-speed gas flow with low pressure promotes effective particle breakage, while controlled velocity and pressure gradients in the classification zone enable precise particle size separation. Optimizing nozzle design, working gas pressure, and temperature results in efficient grinding, uniform product size, and adaptable process control, ensuring the jet mills can handle various material properties and achieve desired fineness.

About Epic Powder

Epic Powder specializes in providing advanced powder processing solutions, including jet milling systems equipped with precise gas velocity and pressure control mechanisms. Our technologies ensure high grinding efficiency, narrow particle size distribution, and contamination-free processing for a wide range of materials, from metals and ceramics to battery compounds. With a focus on innovation and reliability, Epic Powder supports industries in achieving superior product performance and manufacturing excellence.