Pigments are indispensable in industries such as coatings, plastics, inks, cosmetics, and more, where their physical and chemical properties directly impact product performance and appearance. At Qingdao EPIC Powder Machinery Co., Ltd., we recognize that producing high-quality pigments demands precise control over particle size, purity, and consistency. Jet mills have proven to be an exceptional choice for ultrafine grinding of pigments, especially when manufacturers seek contamination-free, highly uniform powders without introducing heat damage.

This article explores the key characteristics of pigments and explains why jet milling technology is particularly suited to meet the complex requirements of pigment production, from grinding efficiency to product quality.

Characteristics of Pigments in Grinding

Pigments typically comprise finely divided solid particles that impart color by absorbing and reflecting light. Their particle size and distribution profoundly influence color strength, opacity, gloss, and dispersibility. Achieving a narrow and consistent particle size distribution is crucial, as it prevents issues like color inconsistency, sedimentation, and poor texture in end products. Moreover, pigments need to maintain chemical and physical stability to resist degradation caused by heat, light, or chemical exposure. Purity is another essential factor since even trace contamination can affect the pigment’s hue or performance, particularly in demanding applications such as cosmetics or food packaging.

For optimum pigment quality, it is essential to control these attributes throughout the milling process, which is why selecting the right grinding technology is fundamental.

Why Jet Mills Excel in Pigment Production

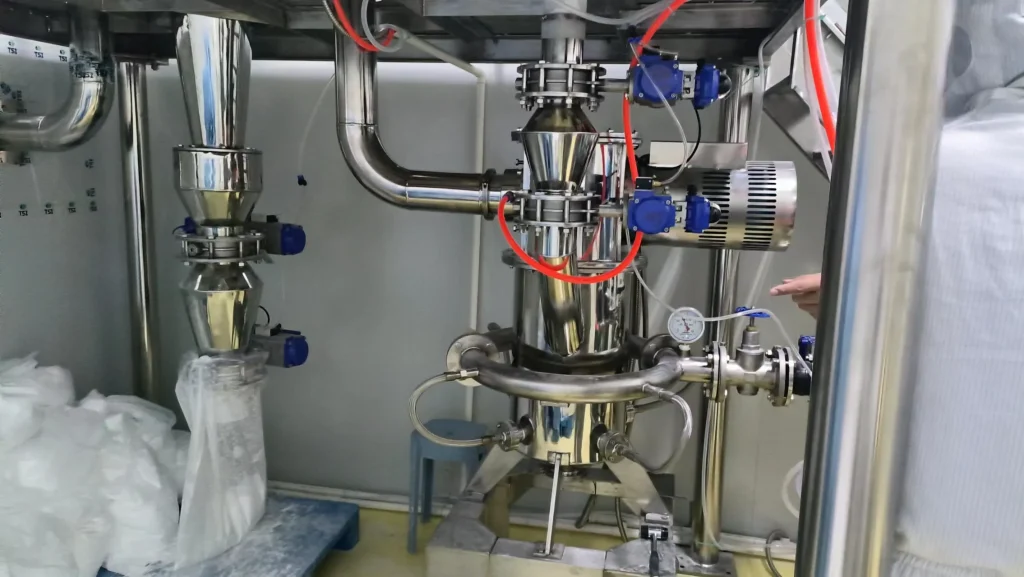

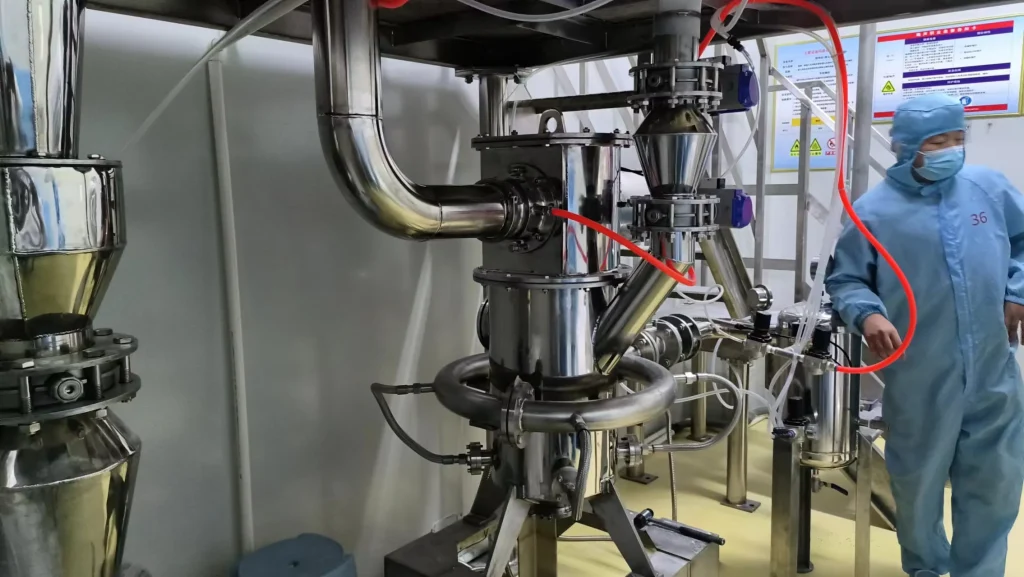

Jet milling stands out as a highly effective technology for producing ultrafine pigment powders due to its unique operational principles. Unlike traditional mechanical mills, jet mills utilize high-velocity gas jets—often air or inert gases—to induce particle collisions within a grinding chamber. This fluid energy breaks down particles without the need for moving mechanical parts contacting the material, which significantly reduces contamination and extends equipment life.

One of the most significant advantages of jet mills is their ability to precisely control particle size by adjusting the gas pressure, feed rate, and grinding time. Operators can achieve finely tuned particle sizes ranging from several microns down to sub-micron levels with a narrow size distribution, all of which contribute to enhanced color strength and uniform pigment performance.

Furthermore, jet milling operates with minimal heat generation due to the adiabatic expansion of gases during the grinding process. This feature is particularly beneficial for heat-sensitive pigments — such as many organic pigments — where exposure to elevated temperatures could lead to chemical degradation or loss of color intensity. By maintaining low grinding temperatures, jet mills preserve the inherent qualities of these delicate pigment materials.

Since jet mills conduct size reduction through particle-on-particle impact within a gas stream, abrasion and wear are localized and limited primarily to wear-resistant linings and nozzles. This design reduces the chance of metal contamination, a common issue in conventional mills with moving mechanical parts. To further ensure product purity, jet mills can be constructed or lined with materials like ceramic or silicon carbide, making them ideal for producing pigments that require stringent contamination controls.

Operational and Performance Benefits

Jet mills offer continuous operation capabilities, enabling manufacturers to scale production from laboratory batches to full industrial volumes without altering the milling principle. This scalability helps maintain consistent product quality across different production scales, which is vital for business growth and customer satisfaction.

Another key benefit is that jet mills can efficiently grind a diverse range of pigment types, including inorganic pigments like titanium dioxide and iron oxides, as well as a variety of organic pigments. Their ability to handle hard, abrasive, and friable materials while maintaining precise control over particle size and quality enables pigment manufacturers to optimize their formulations for multiple applications.

Due to their fluid energy design, jet mills also tend to be energy-efficient when producing ultrafine powders, especially compared to mechanical grinding methods that may require multiple processing steps or additional classification stages.

Application Examples in Pigment Manufacturing

In the coatings industry, jet-milled pigments deliver consistent opacity, brightness, and gloss, helping paints and varnishes achieve superior aesthetics and durability. These finely ground pigments ensure smooth paint flow and minimize settling, resulting in longer shelf life and better application properties.

Printing inks benefit from jet milling as it produces pigments with uniform particle sizes and minimal contamination, which translates into brighter colors, improved print resolution, and greater stability during printing and storage.

In plastics and masterbatch applications, jet-milled pigments enhance coloration uniformity, UV resistance, and whether for conductive or decorative purposes, they contribute significantly to the material’s performance and appearance.

For cosmetic products such as powders and lipsticks, the purity and fine particle size enabled by jet milling improve skin feel, color intensity, and safety by eliminating metal contamination risks.

Conclusion

Jet milling technology presents a superior solution for producing high-quality pigments by providing precise particle size control, narrow distributions, low-temperature operation, and contamination-free grinding. Its continuous, scalable process and adaptability to a wide range of pigment materials make it indispensable for manufacturers aiming to meet today’s rigorous quality standards across coatings, inks, plastics, cosmetics, and beyond.

As a trusted supplier, EPIC Powder Machinery Co., Ltd. is dedicated to delivering advanced jet mill solutions tailored to customer needs, backed by comprehensive technical support to optimize pigment production processes and enhance product competitiveness.

For detailed consultations or to discover how our jet milling technology can transform your pigment manufacturing, please reach out to our expert team. Together, we can deliver innovations that help you achieve excellence in ultrafine pigment production.