What Is Silicon Carbide?

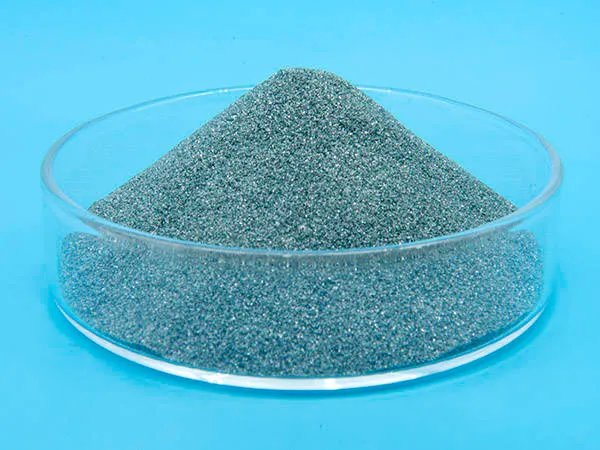

Silicon carbide (SiC) is an inorganic compound. It is a semiconductor and occurs naturally in the extremely rare mineral moissanite. Silicon carbide is commonly available in two varieties: black silicon carbide and green silicon carbide, both of which are α-SiC. The particle size of silicon carbide ground by ਜੈੱਟ ਮਿਲਿੰਗ typically ranges from 3 to 100 microns (d97). It’s depending on the type of equipment, process parameters, and raw material characteristics. Black silicon carbide contains approximately 95% SiC and has higher toughness than green silicon carbide. It is mainly used for processing materials with low tensile strength. Glass, ceramics, stone, refractories, cast iron, and non-ferrous metals can use it during production.

Green silicon carbide contains over 97% SiC and has excellent self-sharpening properties. It is primarily used for machining carbide, titanium alloys, and optical glass. It is also used for honing cylinder liners and fine-grinding high-speed steel tools.

Cubic silicon carbide, a yellow-green crystal produced using a special process, is suitable for superfinishing bearings. Grinding tools made from it can reduce surface roughness from Ra 32–0.16 microns to Ra 0.04–0.02 microns in a single pass.

Uses of Silicon Carbide

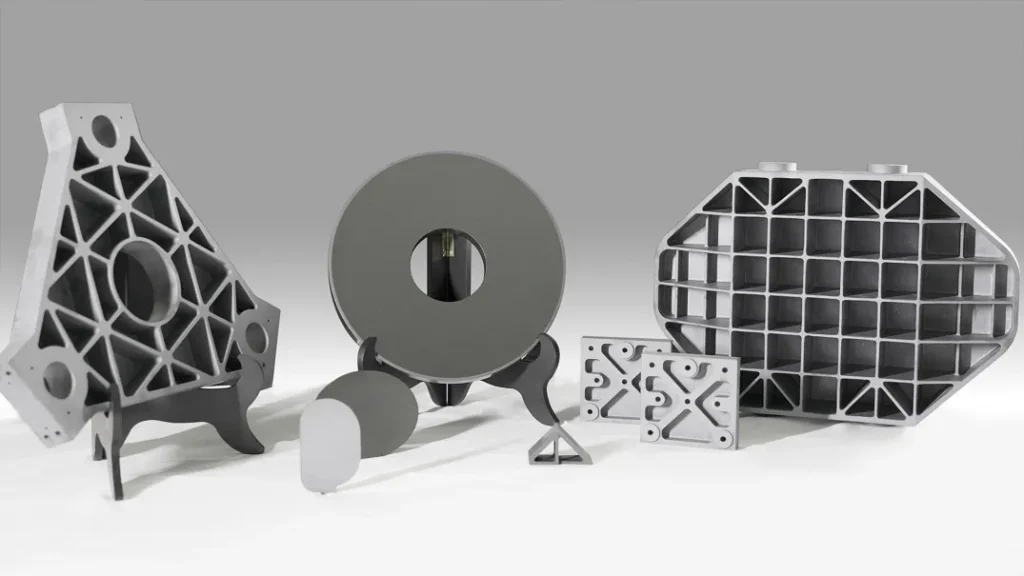

Thanks to its stable chemical properties, high thermal conductivity, low thermal expansion coefficient, and excellent wear resistance, silicon carbide has many applications beyond abrasives. For example: A special process can be used to apply silicon carbide powder to the inner walls of turbine impellers or cylinder blocks, enhancing wear resistance and extending service life by 1–2 times. High-grade refractory materials made from silicon carbide offer thermal shock resistance, compactness, light weight, high strength, and energy efficiency. Low-grade silicon carbide (around 85% SiC) serves as an excellent deoxidizer in steelmaking, improving steel quality and facilitating composition control. Silicon carbide is also widely used in the production of silicon carbide rods for electric heating elements.

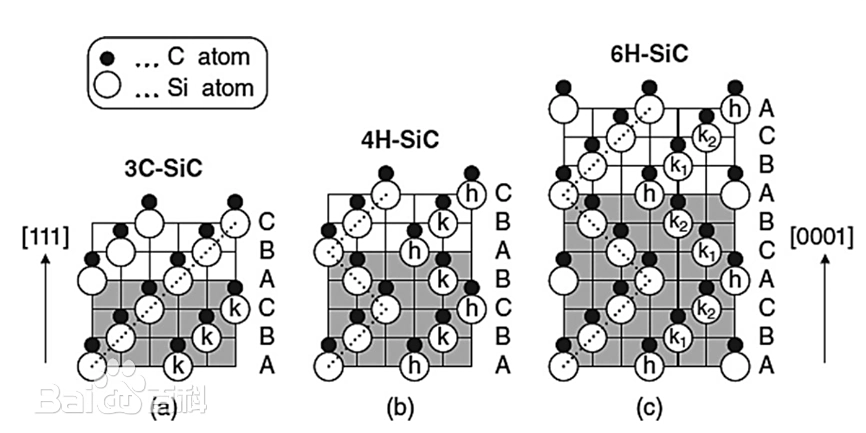

Material Structure and Particle Size Range

The particle size of silicon carbide ground by jet milling typically ranges from 3 to 100 microns (d97). It’s depending on the type of equipment, process parameters, and raw material characteristics.

Typical Particle Size: Fluidized bed jet milling produces a concentrated particle size distribution. It won’t be over-grinding and typically achieves a d97 of 3–100 microns.

Particle Shape and Distribution: The resulting particles have a good shape and a narrow size distribution. This makes them suitable for applications with strict particle size requirements.

Factors Affecting Particle Size

1. Equipment Type

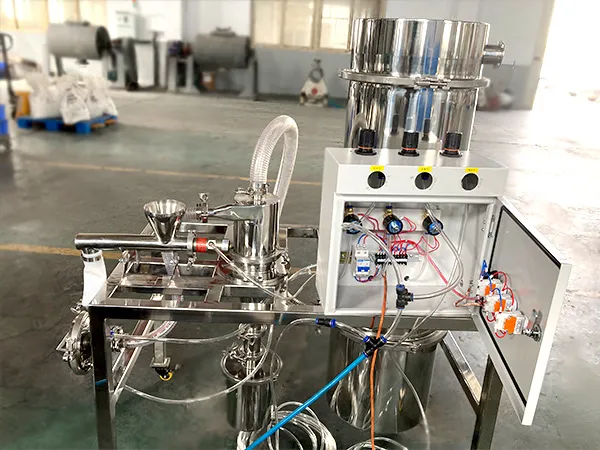

Fluidized Bed Jet Mill: Uses high-pressure gas to accelerate material particles. It causes them to collide at the intersection of nozzle jets. This method offers high crushing capacity and precise particle size control.

Flat ਡਿਸਕ ਜੈੱਟ ਮਿੱਲ: Uses a swirling motion in the milling chamber, causing particles to impact, collide, and rub against each other and the mill surface. However, its particle size control may be slightly less precise than that of a fluidized bed jet mill.

2. Process Parameters

Airflow pressure, nozzle velocity, and classifier speed all directly influence pulverization efficiency and particle size distribution.

3. Raw Material Properties

The hardness, purity, and other characteristics of silicon carbide also affect pulverization difficulty. Generally, higher hardness and purity make the material more challenging to grind, but by optimizing process parameters, jet mills can still achieve efficient pulverization.

Advantages of Jet Milling for Silicon Carbide

No Liner Wear: Fluidized bed jet mills can grind products of varying hardness without liners, resulting in low equipment wear and suitability for long-term continuous production.

Clean and Environmentally Friendly: The fully enclosed pulverization system generates low dust and noise, ensuring a clean, eco-friendly production environment.

Energy Efficiency: Jet mills use nearly all the energy from the gas to accelerate materials over a short distance, achieving high pulverization capacity with relatively low energy consumption.

ਐਪਿਕ ਪਾਊਡਰ ਮਸ਼ੀਨਰੀ

ਐਪਿਕ ਪਾਊਡਰ ਮਸ਼ੀਨਰੀ is a leading manufacturer of ultrafine grinding and classification equipment, specializing in solutions for non-metallic minerals, chemicals, battery materials, and advanced ceramics. With European core technology and decades of industry experience, our equipment delivers stable performance, precise particle size control, and energy-efficient operation, helping clients worldwide achieve higher product quality and productivity.