Alpha alumina (α-Al2O3)is renowned for its superior hardness, chemical stability, and thermal resistance. It is fundamental in industries such as abrasives, ceramics, electronics, and refractories. EPIC poeder Machinery specializes in advanced jet frezen technologies that optimize the production process of alpha alumina powders.

1. Characteristics and Production of Alpha Alumina

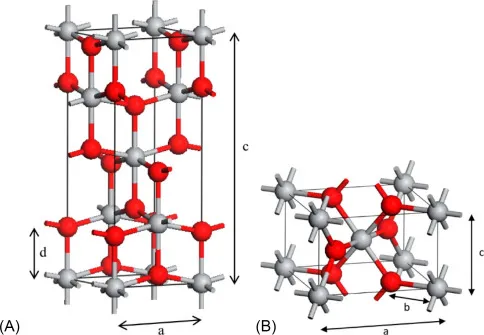

Alpha alumina is the thermodynamically stable phase of alumina and typically produced by calcination of transition aluminas (e.g., gamma alumina). The crystallographic transformation to α-Al2O3 requires precise thermal treatment generally above 1200°C. Recent studies demonstrate that mechanochemical activation by dry milling techniques can lower this phase transition temperature by up to 400°C, enhancing process efficiency and producing finer crystallite sizes (up to 25%-40% smaller than conventional methods).

Fine alpha alumina powders with average particle sizes below 0.3 μm exhibit exceptional sintering and mechanical properties, central to manufacturing cutting-edge functional ceramics and abrasives.

2. Jet Milling Technology for Alpha Alumina

Process Principles

Jet milling utilizes high-velocity compressed air jets to induce particle collisions that reduce particle size without mechanical grinding surfaces. This contact-free method minimizes contamination, a critical advantage for high-purity alpha alumina applications.

Key Milling Considerations for Alpha Alumina

Feed Material Preparation: Pre-calcination to obtain stable transition alumina phases and control moisture content is vital to prevent agglomeration during milling.

Material Hardness and Abrasiveness: Alpha alumina’s hardness necessitates durable milling chambers and nozzle materials, typically ceramics or specialized stainless steel to withstand wear.

Particle Size Distribution Control: Integration of adjustable classifier wheels allows narrow PSD control, crucial for achieving powders with D50 typically between 0.3–2.5 μm and D90 below 3.5 μm, as supported by comparative studies with ball milling methods.

Thermal Management: Because milling generates heat, temperature control maintains powder stability and prevents unwanted phase changes.

3. Data-Driven Industry Insights

| Parameter | Value/Range |

| Typical α-Al2O3 phase conversion temperature without milling | ~1300°C |

| Reduced phase conversion temperature after mechanochemical milling | ~875–900°C |

| Average crystallite size (post dry milling) | ~0.2 μm |

| Target particle size distribution D50 for ultrafine powders | 0.3–0.8 μm |

| Typical D90 upper limit for milling output | ≤3.5 μm |

| Airflow mill alumina powder particle size (D50) range | 3.0–3.5 μm (larger compared to ball milling) |

These data highlight how integrating mechanochemical techniques prior to or in combination with jet milling can significantly enhance powder fineness, reduce sintering temperatures, and improve material properties.

4. Market Trends and Industry Challenges

Alpha alumina production is tightly linked with high-performance ceramic markets and abrasives with increasing demand driven by electronics, automotive, and aerospace sectors. The ultrafine alumina market has seen forecasted annual growth rates exceeding 6% due to the material’s critical role in emerging technologies.

Challenges include:

Energy Consumption: Thermal conversion and milling processes are energy-intensive; innovations focus on reducing temperatures and improving milling efficiency.

Material Purity: Maintaining ultra-high purity (up to 99.999%) in alpha alumina is crucial, making contamination control in jet pulverizers a focal design parameter.

Environmental Regulations: Responsible sourcing and reduced carbon footprint are pressing concerns, influencing process optimization.

5. EPIC Powder Machinery’s Approach

EPIC Powder Machinery’s Jet pulverizers incorporate:

Wear-Resistant Components: Use of ceramic linings and advanced alloys for prolonged service life.

Optimized Classification: Frequency-controlled classifiers enabling precise PSD tailoring adapted to alpha alumina specifications.

Process Automation: Real-time monitoring and control systems to sustain quality and throughput.

Energie-efficiëntie: Design innovations reduce compressed air consumption without sacrificing milling performance.

Conclusie

Producing high-quality alpha alumina powder entails mastering the delicate balance between precise phase control, particle size distribution, and contamination prevention. Jet milling, enhanced by mechanochemical pre-treatment, represents a cutting-edge method that meets these demands efficiently. EPIC-poedermachines remains committed to delivering solutions that integrate technical excellence with market insights, enabling our partners to excel in alpha alumina powder production and beyond. Feel free to Neem contact met ons op for a tailored solution.