As professionals in ultrafine grinding technology and equipment supply, the experts at EPIC Powder Machinery understand that uninterrupted production is crucial to our customers’ success. Minimizing unscheduled downtime for jet milling machines not only boosts productivity but also protects your investment. It ensures consistently high performance. Below, we share three precise jet mill maintenance strategies that leading technical specialists and equipment suppliers recommend for optimal jet mill reliability.

1. Make a Preventive Cleaning Plan

Jet mills stand out for their simple design and lack of mechanical grinding components. However, regular cleaning is essential even with fewer moving parts. Residual powders, static buildup, and accumulated fines can compromise airflow and particle size distribution.

After each product batch, thoroughly clean all contact surfaces with a dry cloth, soft brush, or high-powered industrial vacuum. Avoid using pressurized air or water near classifier motor bearings to prevent damage. Schedule periodic detailed inspections of internal liners and gas nozzles for signs of blockage or buildup. Routine cleaning not only preserves product purity (critical in food and pharmaceutical applications) but ensures consistent milling performance.

2. Check and Monitor Wear Parts Regularly

Although jet mills have no direct-contact grinding media, certain components such as liners, injector nozzles, and classifier wheels (if present) are subject to wear from high-velocity particle collisions.

Develop a checklist for regular inspection of wear-prone parts based on your production intensity.Replace ceramic liners, nozzles, or classifier parts at the first sign of significant wear to prevent efficiency loss or unexpected breakdowns. Source genuine replacement parts from your trusted supplier to guarantee compatibility and performance. By staying ahead of wear, companies can avoid sudden failures and maintain precise particle size specifications.

3. Regularly Inspect and Maintain Related Systems

Stable jet mill operation depends on more than just the mill body — supporting systems like compressed air, dust extraction, and control sensors play vital roles.

Ensure all air compressors, filters, and dryers deliver clean, dry, and oil-free air to avoid contamination and blockages. Inspect and calibrate pressure, temperature, and flow sensors to guarantee safe and efficient operation. Maintain filters and check for any leaks or filter clogging that could disrupt airflow and reduce mill performance.

Conclusion:

By implementing these three jet mill maintenance strategies — regular wear inspection, air optimization, and proper cleaning, you can significantly reduce unplanned downtime and extend the lifespan of the jet milling machine.

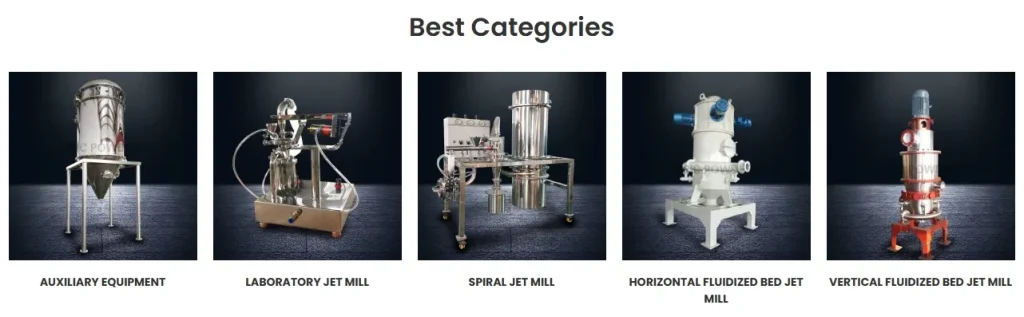

At EPIC Powder Machinery, we provide high-quality jet mills and expert technical support to ensure your powder processing operations run smoothly. Contact us today to learn more about our solutions for your grinding needs!