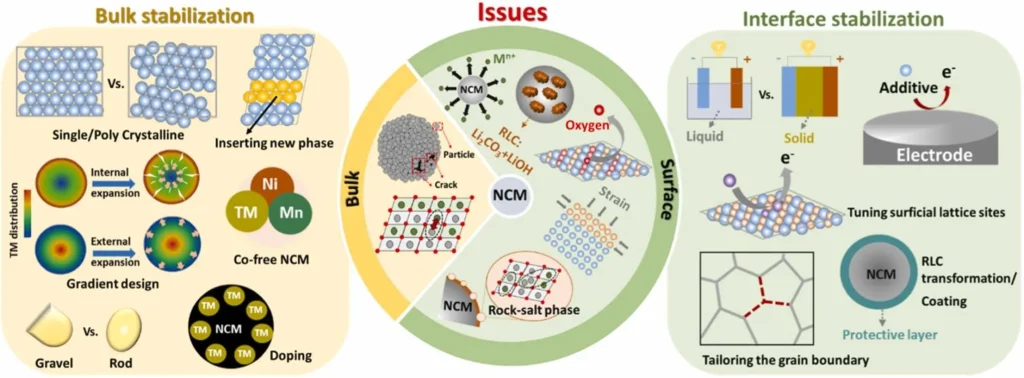

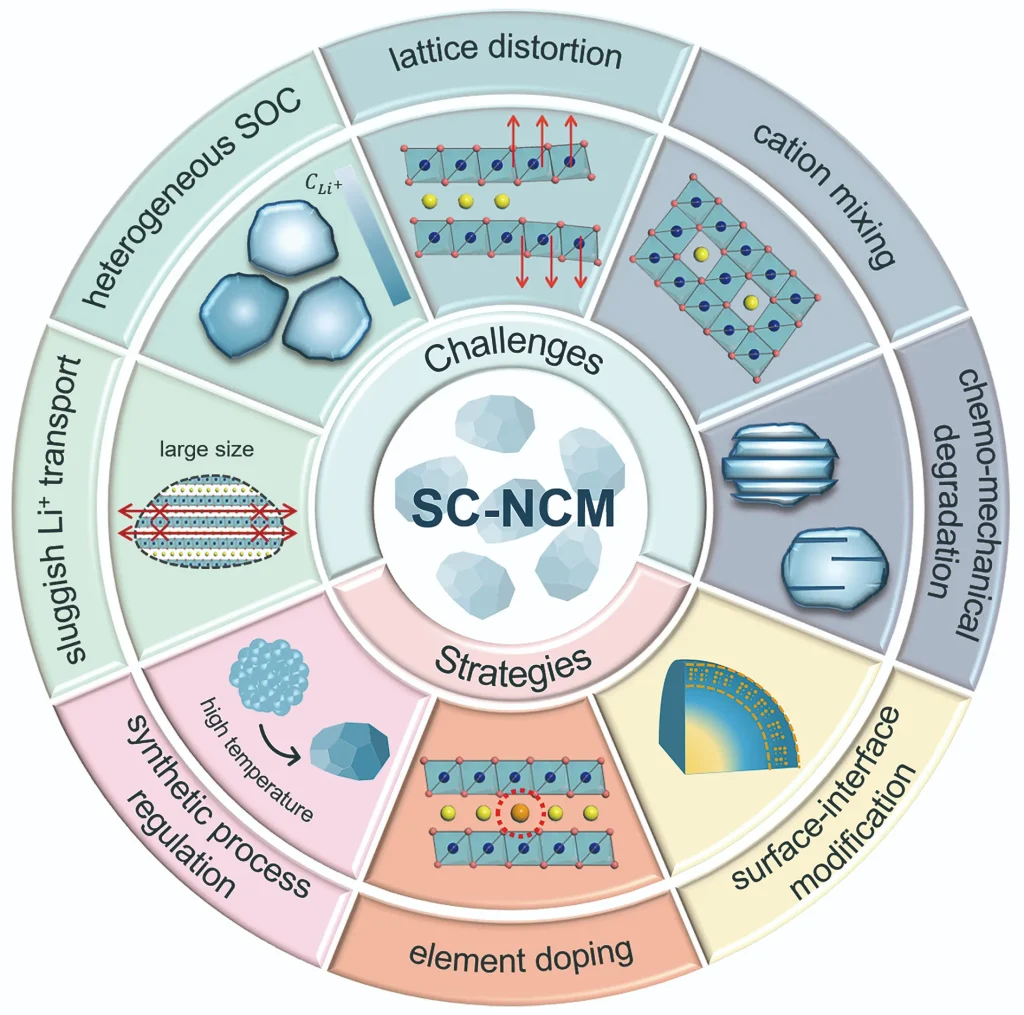

NCMとNMAは、それぞれニッケルコバルトマンガン(NCM)酸化物とニッケルコバルトアルミニウム(NMA)酸化物と呼ばれる層状リチウムイオン電池正極材料の一種です。これらの材料は、遷移金属(ニッケル、コバルト、マンガンまたはアルミニウム)とリチウムを組み合わせることで、電気自動車や携帯型電子機器に不可欠な高エネルギー密度を実現します。LiNixCoyM1−x−yO2の組成式におけるこれらの金属の比率を変えることで、エネルギー密度、安定性、コストなどの特性を調整できます。NCM/NMA(ニッケル-コバルト-マンガン/アルミニウム)正極材料は、高エネルギー密度、優れたサイクル特性、そしてコスト面での優位性を備えており、リチウムイオン電池にとって不可欠な正極材料です。

化学組成と正極材料

NCM/NMA材料:NCM/NMA材料の正極は、ニッケル(Ni)、コバルト(Co)、マンガン(Mn)、またはアルミニウム(Al)を含む化合物で構成され、通常はLi(NixCoyMnz)O2またはLiNixCoyAlzO2と表記されます。ニッケル、コバルト、マンガン、またはアルミニウムの比率は、特定の要件に応じて調整できます。

LFPバッテリーの材料:LFPバッテリーの正極材料はリン酸鉄リチウム(LiFePO4)です。これは鉄、リン、酸素、リチウムの4つの元素で構成されています。鉄とリンの原子比は1:1、リチウムと酸素の原子比は1:4です。

パフォーマンス特性

エネルギー密度:NCM/NMA材料はエネルギー密度が高く、同じ体積または重量でより多くの電気エネルギーを蓄えることができます。これにより、より長い走行距離を実現できます。一方、LFPバッテリーはエネルギー密度が低くなります。

安全性:LFPバッテリーは、安定した結晶構造により熱分解や燃焼の影響を受けにくく、高い安全性を備えています。一方、NCM/NMA材料は高温下での安定性が低く、熱暴走の影響を受けやすいため、より厳格な安全対策が必要となります。

サイクル寿命:LFPバッテリーはサイクル寿命が長く、通常は数千サイクル、場合によっては数万サイクルに達します。NCM/NMA材料のサイクル寿命は比較的短く、通常は約1,000サイクルです。

温度適応性:LFPバッテリーは-20℃~60℃の温度範囲で動作し、優れた適応性を示します。NCM/NMA材料の温度適応性は、その組成や製造プロセスによって異なりますが、一般的にLFPバッテリーほど広くはありません。

コストと適用分野

コスト:LFPバッテリーは比較的低コストであるため、新エネルギー車分野で広く採用されています。NCM/NMA材料はコストが高いものの、高いエネルギー密度という利点から、ハイエンド電気自動車や高性能バッテリーシステムに広く使用されています。

用途:性能の違いにより、LFPバッテリーは、エネルギー密度はそれほど重要ではないものの、コストと安全性が優先される用途、例えば電気バスや物流車両に適しています。一方、NCM/NMA材料は、高いエネルギー密度が不可欠な乗用車に適しています。

まとめると、NCM/NMAとLFPのバッテリー材料は、化学組成、性能特性、コスト、そして用途において大きく異なります。バッテリー材料を選択する際には、実際のニーズと使用シナリオに基づいてこれらの要素を比較検討することが重要です。

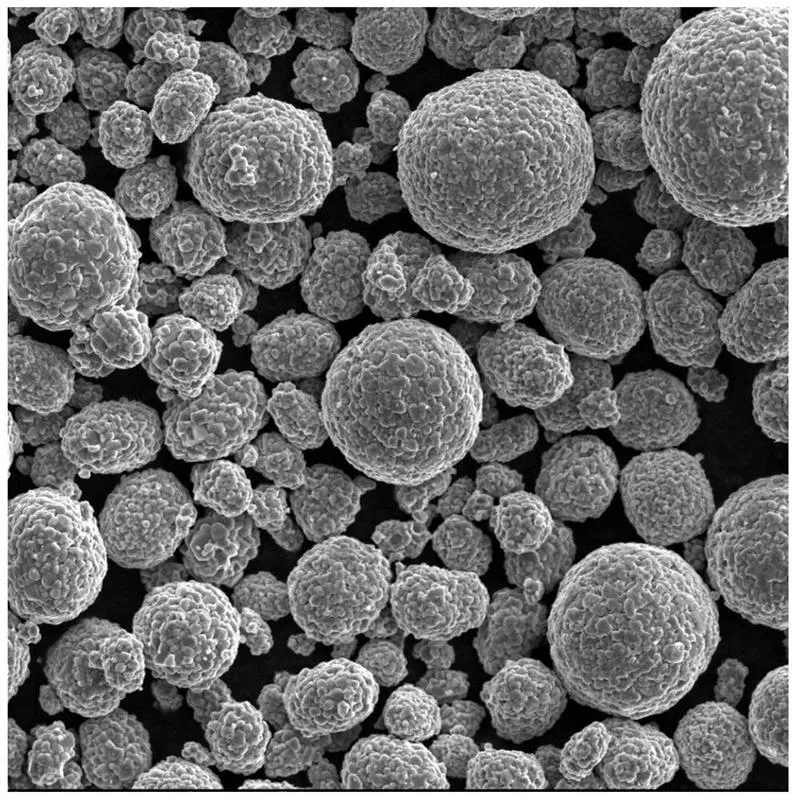

エピックパウダー

エピックパウダー 高度な粉体処理ソリューションの開発において豊富な経験を有しています。様々な電池材料の粉砕に最適な装置を提供することに尽力しています。 エピックパウダーのテクノロジーは、粉体塗装業界の進化する需要に合わせてカスタマイズされた優れた結果を保証します。