Organic bentonite powder is prized for its swelling properties, rheology modification, and adsorption capabilities in cosmetics, coatings, and polymer composites. Achieving a narrow particle-size distribution with high purity requires careful selection of grinding and classification equipment. A bentonite ジェットミル with integrated classification can deliver uniform, sub-10 micron products while minimizing thermal degradation and contamination. From a supplier’s perspective, the right combination of material compatibility, process control, and total cost of ownership drives long-term performance and reliability. A well-tuned benbonite jet mill can produce a tight particle size distribution at low bulk temperatures.

Organic bentonite is a clay mineral with a layered silicate structure, often sensitive to heat and moisture. It benefits from dry grinding with minimal particle agglomeration and controlled surface modification to maintain flow and dispersion in end-use media.

A well-tuned air jet mill can produce a tight particle size distribution at low bulk temperatures. This precise size control enhances dispersion stability in paints, polymers, and personal care formulations, reducing the need for downstream milling. It also reduces contamination risk by eliminating mechanical contact, which is critical for pharmaceutical or cosmetic-grade bentonites.

Choosing the Right Jet Mill

Choosing the right air jet mill for pulverizing organic bentonite requires comprehensive consideration of factors such as material characteristics, process requirements, and equipment performance. The following are key points:

Process Requirements

Particle Size Control: Organic Bentonite requires stringent particle size control, often demanding micron or even nanometer-level precision. Fluidized bed jet mills achieve a narrow particle size distribution through precise classification wheel adjustment, while opposed-jet mills utilize high-speed inter-particle collision to deliver high grinding efficiency and excellent particle size controllability.

Production Capacity Matching: Equipment selection should align with production scale. Benchtop models are suitable for laboratory or pilot-scale trials, whereas large-scale industrial production calls for vertical or horizontal systems to balance throughput and operational costs.

Special Process Requirements: For processing high-temperature, flammable, or explosive materials, incorporate protective measures such as inert gas circulation and explosion-proof design. When ultra-high product purity is essential, select mills equipped with ceramic linings or other high-purity material internals to minimize contamination risks.

Equipment Performance

Grinding Efficiency & Energy Consumption

Fluidized bed jet mills are characterized by low energy consumption. This makes them well-suited for large-scale continuous production. In contrast, opposed jet mills offer high grinding intensity but consume more energy, necessitating an evaluation based on operational cost considerations.

Classification Accuracy

High-performance jet mills are equipped with precision classification mechanisms that effectively separate coarse and fine powders, minimizing the risk of over-grinding or inconsistent particle size distribution. It is advisable to select equipment with an adjustable classifier speed to accommodate varying fineness requirements.

Automation Capability

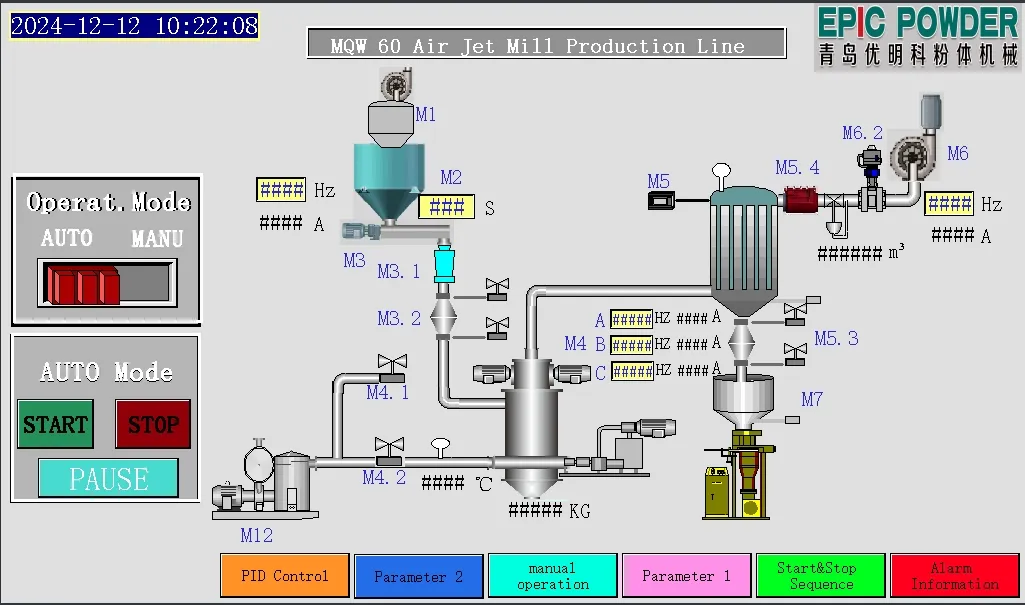

Systems with PLC-based touchscreen controls are recommended. These should support parameter storage, real-time monitoring, and remote adjustment to enhance production consistency and facilitate quality management.

Materials and Maintenance

Wear-Resistant Materials: Critical components such as the grinding chamber and nozzles should be manufactured from wear-resistant materials including hard alloys, ceramics, or high-chromium stainless steel. This enhances equipment durability and lowers long-term maintenance costs.

Easy Cleaning and Maintenance: The equipment design should eliminate hard-to-reach areas, allow for easy disassembly and cleaning, and minimize residue accumulation that could affect product quality. Regularly inspect nozzles for wear and replace vulnerable parts in a timely manner.

Total Cost

Purchase Cost: Fluidized bed jet mills carry a higher price tag but offer lower long-term operating costs. Opposed jet mills require relatively lower initial investment, yet may incur higher energy consumption and maintenance expenses. A comprehensive evaluation balancing budget constraints and production efficiency is essential.

Operating Cost: Select cost-effective equipment by considering factors such as air source pressure, energy consumption, and replacement frequency of wear parts. Some manufacturers offer equipment leasing or customized services, allowing flexible selection based on actual operational needs.

EPIC Powder Recommended Models:

流動層ジェットミル: Ideal for large-scale continuous production, this mill type delivers a narrow particle size distribution and low energy consumption. It is particularly suitable for lithium iron phosphate applications that demand high product purity and precise control over particle size.

ディスクジェットミル: Known for high grinding efficiency and the ability to process high-hardness materials, this model is well-suited for small-batch production or applications requiring exceptional particle size uniformity.

Prior to procurement, it is advisable to engage with equipment manufacturers and provide material samples for grinding tests. This helps obtain practical processing data and performance results, ensuring the selected system accurately matches production needs

Working Principle Of Bentonite Jet milling Machine

The organic bentonite jet milling production line is mainly composed of a grinding unit (featuring supersonic Laval nozzles as the core technology), cyclone separator, dust collector, electrical control cabinet, air compressor, and other auxiliary components.

The system uses purified, dry compressed gas to accelerate the material to high speeds, transferring substantial kinetic energy. Inside the grinding chamber, this results in intense inter-particle collisions and friction. At the same time, the high-speed gas flow applies strong shear forces to the material, collectively achieving efficient grinding.

MQW Series Jet Mill Features:

This model integrates grinding and classification in a single unit. Qualified fine powder is classified directly inside the mill and collected via a cyclone separator. It avoids over-grinding and improves production efficiency. With variable frequency control, the particle size distribution can be precisely adjusted. It can enable a minimum D97 =15.8 μm with a narrow, consistent distribution profile.

エピックパウダー

When selecting equipment, it’s essential to look beyond the initial price and consider long-term costs. エピックパウダー’s jet mill has low energy consumption and minimal maintenance make it a more cost-effective choice in the long run. At エピックパウダー, we offer a wide range of equipment models and tailor solutions to meet your specific needs.

お問い合わせ today for a free consultation and customized solutions! Our expert team is dedicated to providing high-quality products and services to maximize the value of your powder processing. Epic Powder—Your Trusted Powder Processing Expert.

Posted By Emily Chen

Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative for any further inquiries.