I. Contesto e significato della ricerca

Le batterie agli ioni di litio sono ampiamente utilizzate nelle batterie di potenza, nei sistemi di accumulo di energia e nell'elettronica di consumo grazie ai vantaggi di elevata densità energetica, elevata potenza, lunga durata e rispetto dell'ambiente. Tra i vari materiali catodici, il litio ferro fosfato (LiFePO₄ o LFP) è diventato un materiale catodico di uso comune grazie alla sua elevata sicurezza, al costo relativamente basso e alla buona stabilità strutturale. Tuttavia, le prestazioni di lavorazione dell'LFP influiscono direttamente sulla qualità del foglio elettrodico e sulle prestazioni della batteria, con il processo di frantumazione che rappresenta un passaggio chiave nel controllo della granulometria e della distribuzione delle particelle del materiale. Questo articolo studia sistematicamente gli effetti della velocità di avanzamento e della pressione di macinazione sulla distribuzione granulometrica, sulle caratteristiche della sospensione, sulla qualità del foglio elettrodico e sulle prestazioni elettrochimiche dei materiali LFP, fornendo una base per l'ottimizzazione dei processi nella produzione industriale.

II. Metodi sperimentali

Il precursore LFP è stato preparato utilizzando fosfato di ferro come fonte di ferro tramite un metodo di riduzione carbotermica. Il materiale iniziale, denominato LFP-0, è stato ottenuto dopo essiccazione a spruzzo e sinterizzazione ad alta temperatura. Un precursore di tipo QLM-2 mulino a getto è stato utilizzato per processare LFP-0 a diverse velocità di alimentazione (0,50 kg/h, 0,75 kg/h, 1,00 kg/h, 1,25 kg/h) e pressioni di macinazione (15 m³/h, 18 m³/h, 21 m³/h, 24 m³/h), ottenendo più gruppi di campioni. Le proprietà fisiche del materiale sono state caratterizzate utilizzando un analizzatore granulometrico, un microscopio elettronico a scansione (SEM) e un resistivimetro per polveri. I campioni sono stati quindi trasformati in fogli di elettrodi e celle a sacchetto da 6 Ah per testare sistematicamente la finezza della sospensione, la viscosità, la densità di compattazione del foglio di elettrodi, la capacità e l'impedenza delle celle.

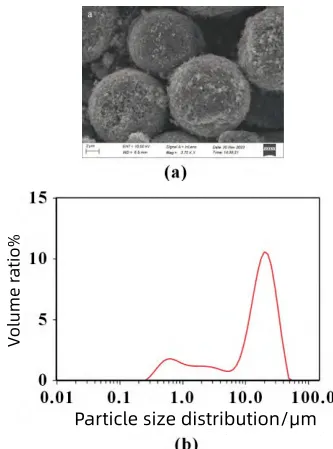

III. Analisi della pre-fresatura iniziale del materiale

Il materiale LFP-0 non macinato era costituito da particelle sferiche con una distribuzione granulometrica concentrata: D₅₀ era di 16,3 μm e Dmax superava i 30 μm. La finezza della sospensione corrispondente raggiungeva 37–39

μm, superando lo standard accettabile della linea di produzione (≤35μm). La densità di compattazione del foglio di elettrodi era di soli 2,17 g/cm³, inferiore ai requisiti per le batterie di potenza e di accumulo di energia (≥2,40 g/cm³). Sebbene la capacità specifica di scarica di 0,1C raggiungesse i 160,8 mAh/g, le scarse prestazioni di lavorazione indicavano la necessità del processo di fresatura.

IV. Impatto della velocità di avanzamento sulle prestazioni LFP

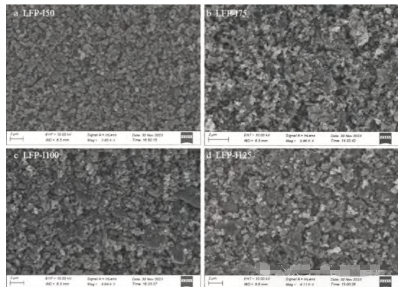

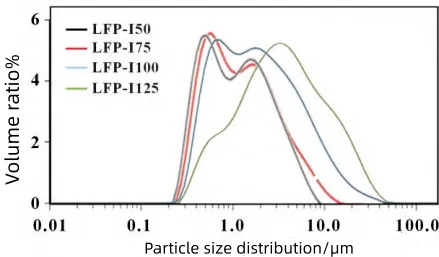

Mantenendo costante la pressione di macinazione a 21 m³/h, è stata studiata l'influenza delle diverse velocità di avanzamento:

1. Dimensioni e morfologia delle particelle: Velocità di avanzamento inferiori hanno portato a una migliore efficienza di macinazione. Le particelle LFP-I50 (0,50 kg/h) erano uniformi con Dmax < 10 μm; LFP-I75 (0,75 kg/h) mostrava una leggera agglomerazione con Dmax < 20 μm; mentre LFP-I100 e LFP-I125, a causa di velocità di avanzamento eccessivamente elevate, presentavano particelle non sufficientemente frantumate con Dmax vicino a 50 μm, simili al materiale iniziale.

2. Prestazioni della sospensione e del foglio di elettrodi: All'aumentare della velocità di alimentazione, la finezza della sospensione è aumentata significativamente (da 21 μm a 42 μm), il contenuto di solidi è leggermente aumentato e la viscosità è rimasta pressoché invariata. La densità di compattazione dei fogli di elettrodi è diminuita da 2,46 g/cm³ a 2,40 g/cm³. Ad alte velocità di alimentazione (ad esempio, 1,25 kg/h), sui fogli di elettrodi sono comparsi agglomerati, bolle e macchie, compromettendone l'uniformità di aspetto.

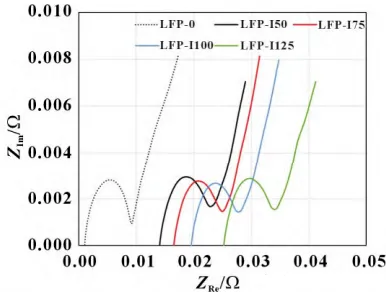

3. Prestazioni elettrochimiche: La capacità specifica di 0,1C per tutti i campioni ha superato i 158 mAh/g, con lievi differenze. Tuttavia, l'impedenza elettrochimica (Rct) è aumentata con velocità di alimentazione più elevate, indicando che velocità di alimentazione eccessivamente elevate danneggiano lo strato di rivestimento in carbonio, aumentando la resistenza interfacciale.

V. Impatto della pressione di macinazione sulle prestazioni LFP

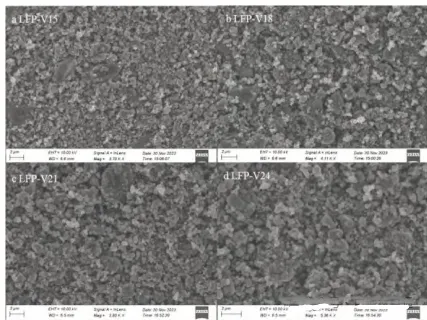

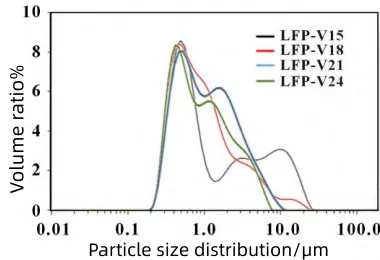

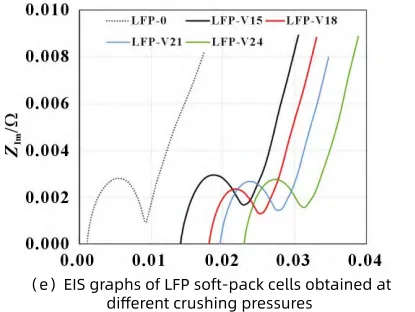

A una velocità di avanzamento costante di 0,75 kg/h, è stata studiata l'influenza delle diverse pressioni di macinazione:

1. Dimensioni e morfologia delle particelle: a una pressione di 15 m³/h, la rottura delle particelle era insufficiente, con Dmax > 10 μm; quando la pressione aumentava a 21 m³/h e oltre, Dmax diminuiva al di sotto di 20 μm; la stragrande maggioranza delle particelle LFP-V24 (24 m³/h) era più piccola di 2 μm, con una distribuzione granulometrica concentrata.

2. Prestazioni di elaborazione: a bassa pressione (15 m³/h), la finezza della sospensione ha raggiunto i 42 μm e sono apparse evidenti sporgenze di particelle sui fogli degli elettrodi; quando la pressione è aumentata a 21 m³/h, la finezza è diminuita a 33 μm e l'aspetto dei fogli degli elettrodi è migliorato; a 24 m³/h, i fogli erano lisci e privi di difetti, con una densità di compattazione che è salita a 2,46 g/cm³.

3. Comportamento elettrochimico: tutti i campioni hanno raggiunto capacità superiori a 159 mAh/g. Tuttavia, l'aumento della pressione di macinazione ha aggravato il danno allo strato di carbonio, con conseguente aumento della resistività della polvere e dell'Rct della batteria.

VI. Ottimizzazione completa e conclusione

Bilanciando il controllo delle dimensioni delle particelle, le prestazioni di lavorazione e le prestazioni elettrochimiche, sono stati determinati i parametri di processo ottimali: velocità di alimentazione 0,75 kg/h, pressione di macinazione 21 m³/h. In queste condizioni:

Dmax è controllato entro 20 μm

La finezza della sospensione è ≤35 μm

La densità di compattazione del foglio di elettrodi è ≥2,44 g/cm³

La capacità specifica di scarica 0,1C è ≥159 mAh/g

Evitando difetti nell'aspetto della lamina dell'elettrodo e un'impedenza eccessivamente elevata.

VII. Suggerimenti per l'applicazione pratica

I produttori di LFP devono adattare dinamicamente il processo di macinazione in base alla distribuzione granulometrica, alla morfologia SEM e agli spettri di impedenza della batteria. Ciò evita di danneggiare lo strato di rivestimento in carbonio a causa di una macinazione eccessiva o di compromettere le prestazioni di lavorazione a causa di una macinazione insufficiente. I parametri delle apparecchiature devono essere selezionati in modo ragionevole per migliorare l'efficienza produttiva, garantendo al contempo la lavorabilità del prodotto e le prestazioni elettrochimiche.

VIII. Valore della ricerca

Questo studio non solo fornisce finestre di parametri specifici e fattibili per il processo di fresatura a getto di materiali LFP, ma approfondisce anche la comprensione della relazione tra distribuzione granulometrica e prestazioni complessive della batteria. Riveste quindi un'importanza fondamentale come guida per il progresso dell'applicazione industriale delle batterie LFP.

Polvere epica

IL Polvere epica Jet Mill si distingue come la scelta ideale per la lavorazione di polveri ad alta richiesta. Offre un'efficienza di macinazione eccezionale e un controllo preciso delle dimensioni delle particelle. Ci impegniamo a creare maggiore valore per i nostri clienti attraverso tecnologie innovative e un supporto post-vendita completo, aiutando la vostra attività a crescere.

Scegli Epic Powder per qualità e affidabilità e lavoriamo insieme per dare forma a un nuovo futuro! Contattaci oggi stesso per una soluzione personalizzata e scopri la tecnologia di lavorazione delle polveri leader del settore!