Extending the service life of an air pulverizer not only helps businesses reduce production costs, but also minimizes operational issues. This responsibility falls on each operator. So, how can we extend the lifespan of the air pulverizer? Here are some key steps to follow:

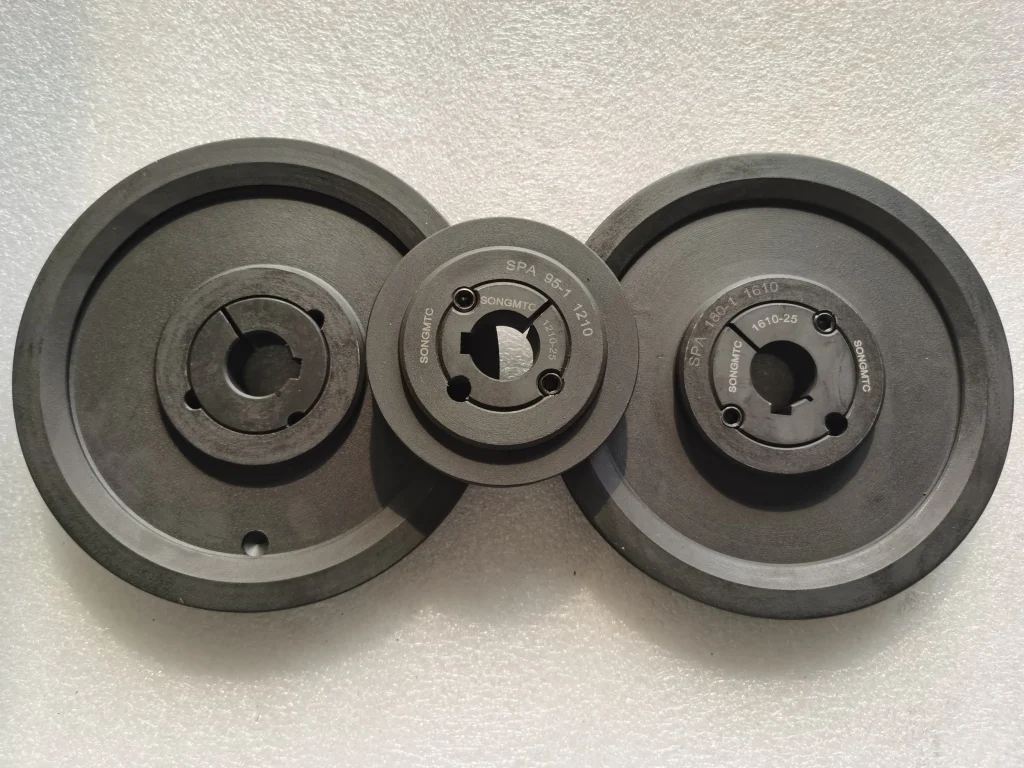

1 Adjust the Pulley Tension

When the machine is new, the pulley belt tends to stretch. It’s crucial to adjust the belt to the proper tension to ensure its longevity.

2 Regular Inspection and Replacement of Wear Parts

Wear parts should be regularly inspected and replaced as needed to maintain production quality and efficiency.

3 Proper Lubrication

The main engine and classifier bearings are lubricated with grease. Use No. 2 special grease with a consistency grade of 265-295 to prolong service life of the air pulverizer .

4 Monitor Bearing Temperature

Frequently check the temperature rise of the bearings during production. If the temperature exceeds 50°C, stop the machine for inspection to identify and resolve the issue.

5 Inspect Blades and Liners

Regularly check the wear on the blades and liners. If any significant wear is found, replace them immediately to prevent a decline in productivity and to avoid coarse particle formation.

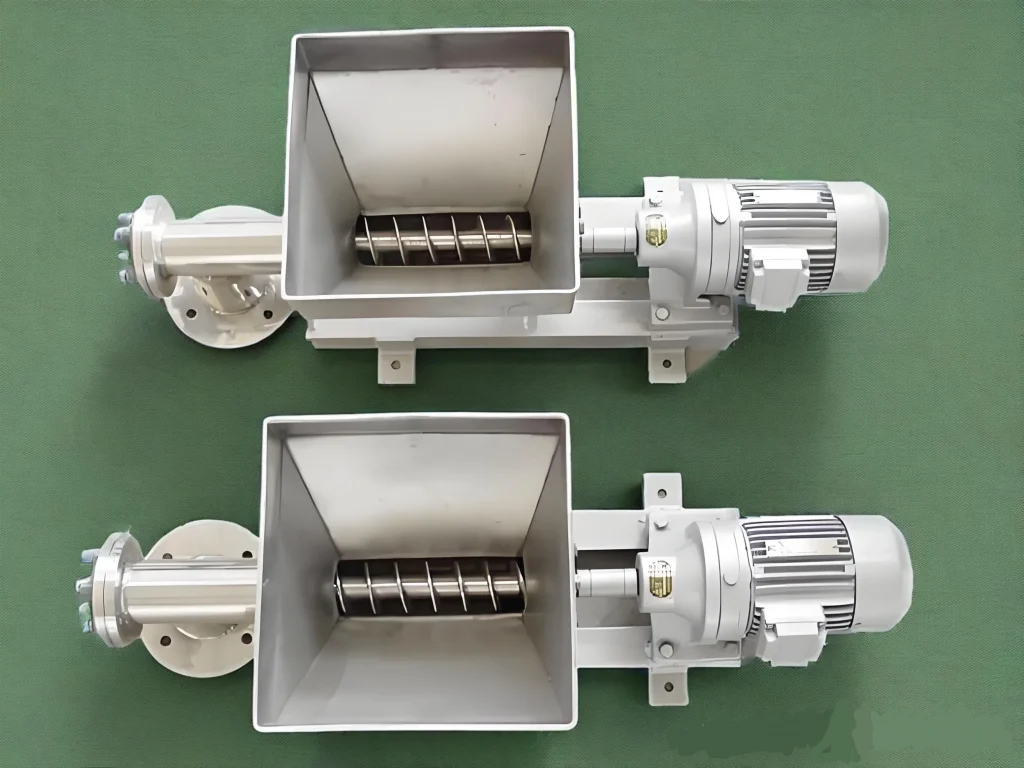

6 Grease Replacement for Spiral Feeder

The spiral feeder grease should be replaced every 4,000 hours, using ordinary calcium-based grease.

7 Bearing Grease Change Interval

Bearings should have their grease changed every 2,000 hours. Ensure that the grease fills 1/2 (upper test) or 3/4 (lower test) of the bearing cavity. Do not overfill the grease, as excessive amounts can cause the bearing temperature to rise.

The jet mill has been popular in the market for many years. With technological advancements, new models are continually being introduced to meet the demands of various material crushing applications. As the market grows, jet mills are evolving to provide more innovative solutions for diverse industries. Moving forward, the design of jet mills will be tailored to meet specific market needs, boosting their performance and contributing to the overall development of society.

It’s important to note that during welding, the metal sheet temperature can change, affecting its microstructure and properties. If overheated, the metal surface oxidizes, causing the formation of brittle particles and coarse grains, which can degrade the material’s quality.

To ensure the reliability of the short-circuit protection device in the jet mill, sufficient short-circuit current must be present to quickly cut off the current. This requires that the wire’s cross-sectional area is adequately sized. A wire that is too small can result in damage, while too large a wire may not activate the protection system reliably.

Preventive Measures: To prevent issues during welding, control the flame to be slightly more neutral than acetylene. Maintain a low welding speed to prevent excessive heat in the molten pool, thereby reducing the risk of metal damage.

In line with industry advancements, the air pulverizer continues to evolve. If you encounter any difficulties or failures during use, feel free to reach out for assistance. We hope to be your trusted partner in creating a better and more efficient working environment.

Epic Powder Machinery

At Epic Powder Machinery, we specialize in the development and production of advanced pulverizing equipment, including air pulverizers designed for high performance and long service life. With our expertise in ultrafine grinding technologies, we are committed to delivering solutions that improve operational efficiency and reduce maintenance costs. Our innovative products are trusted by industries worldwide to meet their most demanding grinding needs.