The fineness achievable with a jet mill depends on various factors. Generally, the particle size ranges from 1 to 45 μm and is adjustable, while certain specialized materials can even reach the nanoscale. Below is a detailed analysis:

Jet Mill Particle Size Range

General Fineness Range: Jet mills typically produce powders with a particle size of 1–45 μm, adjustable based on requirements. They utilize high-speed airflow (300–500 m/s) or superheated steam (300–400°C) to achieve ultrafine grinding of solid materials. This technology is widely applied in processing non-metallic minerals (such as talc, kaolin, barite, graphite, wollastonite, and zircon) as well as other brittle materials.

Specialized Materials: For certain materials, jet mills can achieve nanoscale fineness (e.g., some molybdenum compounds, paint pigments, and similar products can be reduced to 200 nm particles).

Factors Affecting Jet Mill Fineness

1. Initial Particle Size: The feed material should generally be <1 mm—the finer the input, the higher the grinding efficiency and the finer the output.

2. Material Properties: Factors like flowability, moisture content, and particle uniformity matter. Poor flowability, high impurity levels, or excessive solvent content may cause clogging, requiring customized equipment design.

3. Grinding Pressure: Higher grinding pressure increases production capacity and reduces particle size. Optimal pressure varies by material and equipment.

4. Feeding Rate: A slower feed rate improves grinding efficiency and fineness. This can be controlled via a manual butterfly valve or linked to the classifier wheel motor’s current.

5. Equipment Design: Different manufacturers and models yield varying fineness levels, even for the same material.

6. Classifier Wheel Speed: A higher rotation speed reduces the maximum particle size.

7. Nozzle Size: A smaller nozzle throat diameter decreases the median particle size but may lower production capacity.

8. Airflow Volume (Exhaust Fan): Affects yield and efficiency. Excessive airflow may carry coarse particles into the dust collector, while insufficient airflow causes material buildup in the grinding chamber.

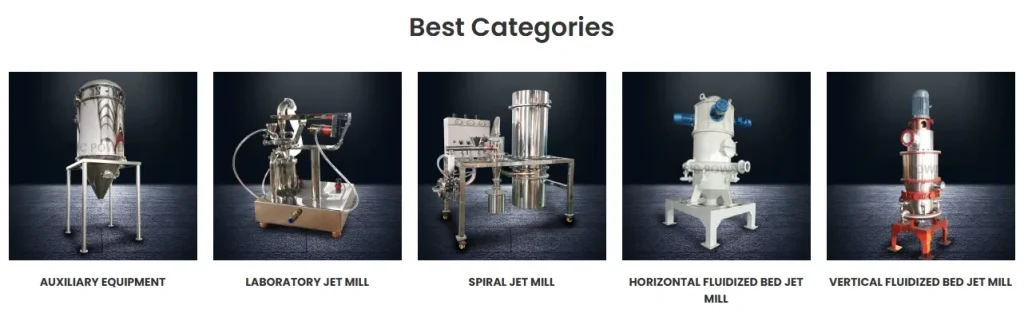

Epic Powder: Your Partner in Ultrafine Grinding Excellence

At Epic Powder, we specialize in jet milling solutions tailored to your material’s unique needs. Trust us to deliver unmatched fineness, efficiency, and reliability for your most demanding powder applications. Achieve the Impossible. Choose Epic Powder.