Biochar is an eco-friendly porous material produced by pyrolyzing agricultural waste (e.g., straw, nutshells). It offers key benefits such as carbon sequestration, soil enhancement, and pollutant adsorption. By stably storing carbon for centuries, it mitigates greenhouse gas emissions. It improves soil water retention and nutrient availability, boosting crop growth, while also immobilizing heavy metals and organic pollutants for ecological remediation. Additionally, biochar upcycles waste into valuable resources, enabling a sustainable “waste-to-cure” cycle. Among biochar materials, coconut shell charcoal, bamboo charcoal and fruit shell charcoal (such as walnut shell charcoal and apricot shell charcoal) are the most common types. Due to different raw materials, they have significant differences in pore structure, specific surface area and adsorption performance, which in turn affects their application in industry, environmental protection, energy and other fields.

This article will compare the differences between coconut shell charcoal and other biochars from four dimensions: pore structure (micropore, mesopore, macropore distribution), specific surface area, adsorption performance and applicable scenarios, to help users choose carbon materials more scientifically.

1. Pore structure:The micropore advantage of coconut shell charcoal is more prominent

The pore structure of biochar is usually divided into:

| Micropores (<2 nm) | Dominant adsorption of small molecules (such as gases, heavy metal ions) |

| Mesopores (2-50 nm) | Affect liquid adsorption (such as organic pollutants) |

| Mesopores (2-50 nm) | Mainly used as transmission channels, affecting permeability |

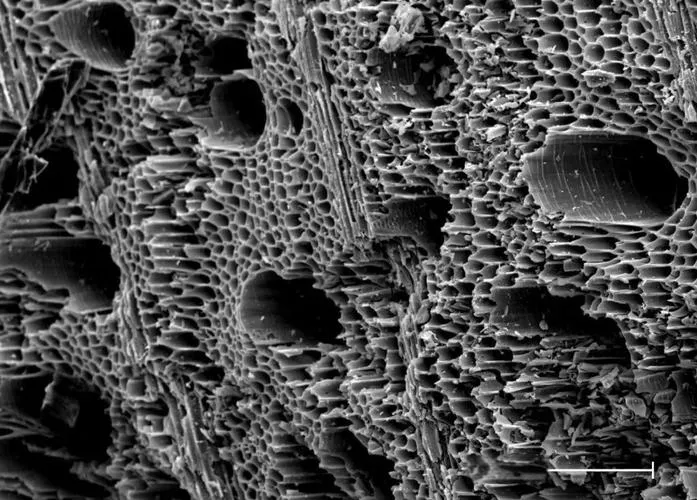

(1) Coconut shell charcoal has well-developed micropores, stronger adsorption of small molecules Coconut shell charcoal can form a highly developed micropore structure after high-temperature carbonization (600-900°C) due to its dense raw materials and special fiber structure, and the proportion of micropores can reach more than 70%. This makes it excellent in gas adsorption (such as VOCs, formaldehyde) and supercapacitor electrode materials.

(2) Bamboo charcoal has more mesopores, suitable for liquid purification. It mainly macropores and a small amount of mesopores, with weak adsorption capacity, suitable for filtering large molecular impurities. After physical activation, bamboo charcoal activated carbon has a high proportion of micropores, up to more than 90%, and can efficiently adsorb small molecule materials.

(3) Fruit shell charcoal (such as walnut shell charcoal): more balanced pore distribution The pore structure of fruit shell charcoal (such as walnut shell, apricot shell) is between coconut shell charcoal and bamboo charcoal, and the distribution of micropores and mesopores is more balanced. It is suitable for water treatment, desulfurization and denitrification, but the specific surface area is usually lower than coconut shell charcoal.

| Coconut shell charcoal | Bamboo charcoal | Fruit shell charcoal | |

| Specific surface area | 1000-1500 m²/g (up to 2000 m²/g or more after activation) | 500-1500 m²/g | 700-1200 m²/g |

Conclusion:

Gas adsorption (such as air purification):

coconut shell charcoal > fruit shell charcoal > bamboo charcoal

Liquid adsorption (such as water treatment):

bamboo charcoal≈ fruit shell charcoal > coconut shell charcoal

2. Specific surface area: coconut shell charcoal is far ahead

The specific surface area (the total surface area of carbon material per unit mass) directly affects the adsorption capacity.

Generally speaking, the larger the specific surface area, the stronger the adsorption performance. Carbon material Specific surface area (m²/g)

Why does coconut shell charcoal have a higher specific surface area? The natural fiber structure of coconut shell is denser, and more micropores can be formed after high-temperature carbonization. Chemical activation (such as KOH, H₃PO₄ activation) can further expand the specific surface area to exceed 2000 m²/g. So coconut shell charcoal is the best for gas adsoption. Bamboo charcoal is suitable for liquid phase adsorption. Fruit shell is suitable for a wide range of scenarios

3. Comparison of adsorption performance: How to choose in different scenarios?

(1) Gas adsorption (VOCs, formaldehyde, energy storage) Best choice: coconut shell charcoal • The microporous structure can efficiently adsorb small molecular gases (such as benzene and formaldehyde).

In supercapacitors, coconut shell charcoal with high specific surface area can provide more active sites and improve energy storage density.

(2) Decolorization (heavy metal, dye removal) Recommended: bamboo charcoal or fruit shell charcoal • The pore structure is more suitable for the adsorption of macromolecular pollutants (such as dyes, organic wastewater).

Coconut shell charcoal may have a slow diffusion rate in water treatment due to excessive micropores.

(3) Desulfurization and denitrification (industrial waste gas treatment) Applicable: fruit shell charcoal or modified coconut shell charcoal • It is necessary to take into account both micropores (adsorption of SO₂/NOx) and mesopores (increase reaction rate), and fruit shell charcoal is more balanced.

Through surface modification (such as loading metal oxides), coconut shell charcoal can also be used in this scenario.

4. Market trend: Why is coconut shell charcoal more popular in the high-end market?

In recent years, the application of coconut shell charcoal in energy storage batteries, high-end air purification, pharmaceutical purification and other fields has grown rapidly. Here are some core reasons: The micropore structure is stable and suitable for high-precision adsorption (such as gold extraction, pharmaceutical carrier). The conductivity is better than bamboo charcoal, and it performs better in sodium negative electrode and supercapacitor. It is highly renewable, and the supply of coconut shell raw materials in Southeast Asia is sufficient and can be produced sustainably.

In contrast, bamboo charcoal and fruit shell charcoal are more used in low-end markets such as environmental water treatment and soil improvement.

5. How to choose the right biomass charcoal?

| Demand scenario | Recommended carbon material | Reason |

| Air purification, VOCs treatment | Coconut shell charcoal | Well-developed micropores, strong adsorption of small molecules |

| Wastewater treatment, decolorization | Bamboo charcoal/fruit shell charcoal | Chemical methods can adjust the proportion of mesopores, suitable for liquid phase adsorption |

| Supercapacitor/battery | Coconut shell charcoal | High specific surface area, good conductivity |

| Industrial desulfurization and denitrification | Modified fruit shell charcoal | Well-developed micropores, mesopores assisted |

Conclusion

Coconut shell charcoal, bamboo charcoal and fruit shell charcoal each have their own advantages. The key is to choose the most suitable material according to the adsorption object (gas/liquid), pore size requirements and cost budget.

With the development of environmental protection and new energy industries, high-end applications of coconut shell charcoal (such as sodium battery negative electrode and energy storage) have broad prospects, while bamboo charcoal and fruit shell charcoal are still competitive in the traditional environmental protection field.

About EPIC Powder Machinery

EPIC Powder Machinery is a trusted manufacturer of advanced powder processing systems based in Qingdao, China. With decades of experience in ultrafine grinding, air classification, and system integration, we provide customized solutions for a wide range of materials, including activated carbon, biochar, and battery-grade powders. Our equipment is known for precision, energy efficiency, and reliable performance—helping customers around the world optimize production and reduce costs. Let EPIC Powder be your partner in high-performance material processing.