10 Specific surface area

The specific surface area of ordinary GCC is generally about 1 m²/g.

For heavy fine calcium carbonate, it ranges from 1.45–2.1 m²/g.

The specific surface area of ordinary PCC is typically about 5 m²/g.

For light fine calcium carbonate, it ranges from 27–87 m²/g.

11 Flowability

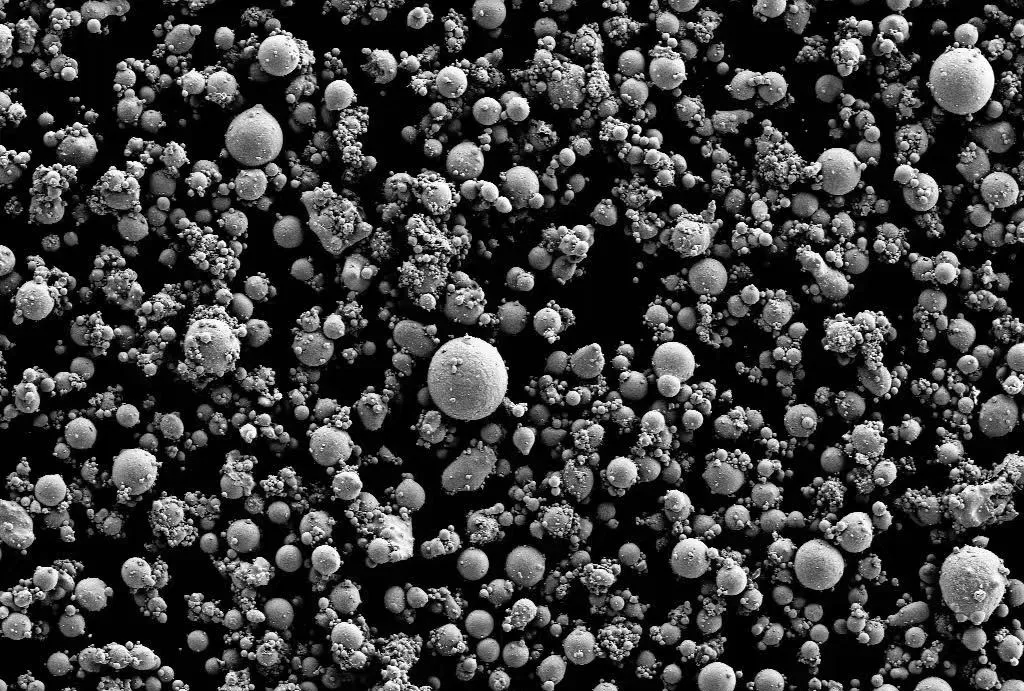

In terms of flowability, the microstructure of PCC is like a spindle shape and has a relatively high oil absorption value. It tends to absorb formulation components that enhance flow, such as lubricants, plasticizers, coupling agents, and dispersants, which reduces its flowability. When the dosage exceeds 25 parts, flowability is significantly affected.

GCC, being granular, helps improve flowability. There is no strict limit on the amount added. From the perspective of flowability, when adding more than 25 parts of calcium carbonate in PVC pipe formulations, GCC is recommended.

12 Price

GCC is produced primarily by mechanical crushing and grinding.

PCC, on the other hand, is obtained through chemical precipitation, a process that is much more complex and requires stricter controls.

As a result, for the same particle size, GCC is about 30% cheaper than PCC. When performance requirements allow, choosing GCC is more economical.

13 Modification function

GCC provides better tensile strength and improves processing flowability. Plastics filled with smaller particle size GCC also perform better.

PCC offers better impact strength and rigidity. Plastics made with PCC generally have a smoother surface and lower density.

14 Color light controllability

Hue refers to the dominant tone of a color, while color light refers to the residual tint. Powders with different crystal forms exhibit different hues. Calcium carbonate has three distinct crystal forms, which result in varying hues.

For GCC, the base color depends on the origin and does not change with crushing or refinement. For example, calcium carbonate from Sichuan appears bluish, from Guangxi appears reddish, and from Jiangxi has a greenish tint.

As for PCC, people can control the crystal form during synthesis, allowing for regulation of the resulting hue. When color matching, the color light of calcium carbonate should be consistent with that of the main pigment.

15 pH value

• The pH value of GCC is 8–9.

• The pH value of PCC is 9–10.

16 Comparison of Mineral Economics

Powder preparation cost: Under conventional conditions, the costs are comparable. However, when including environmental control costs and resource waste, the expansion cost of PCC is higher than that of GCC.

Environmental balance: GCC production primarily generates noise, but no “three wastes” (wastewater, waste gas, solid waste), making it environmentally manageable. PCC production emits all three types of waste, particularly combustion exhaust, resulting in lower overall environmental sustainability.

Resource utilization rate: GCC production allows for more efficient and comprehensive use of mineral resources. In contrast, PCC production struggles to achieve the same level of resource efficiency.

17 Application performance

In papermaking, rubber, and plastics industries, people use GCC. It is typically added in large quantities as a volume filler to reduce product manufacturing costs. PCC has a broader application range, including plastics, rubber, coatings, adhesives, cigarette paper, and inks. It also serves as a volume filler. People often use Nano PCC as a functional filler for modification or reinforcement, typically in smaller amounts.

Conclusion

It is crucial to clearly distinguish between PCC and GCC and to choose the appropriate type when designing a specific formulation. Doing so to select the materials according to performance needs while also helping to reduce costs.

Epic Powder

Thank you for reading this article on the differences between GCC and PCC. As a leader in the powder technology field, Epic Powder Machinery provides efficient and innovative jet mills and related equipment to clients around the world.

Whether you are looking to enhance product performance or optimize production costs, we offer the most suitable solutions for your needs.

If you have any questions about the production and application of calcium carbonate powders, please feel free to contact us.