La micropoudre de silice, en tant que matériau minéral non métallique important, est largement utilisée dans divers domaines tels que les stratifiés cuivrés (CCL), les composés de moulage époxy (EMC), les matériaux isolants électriques, le caoutchouc, les plastiques et les revêtements en raison de ses propriétés physiques et chimiques uniques.

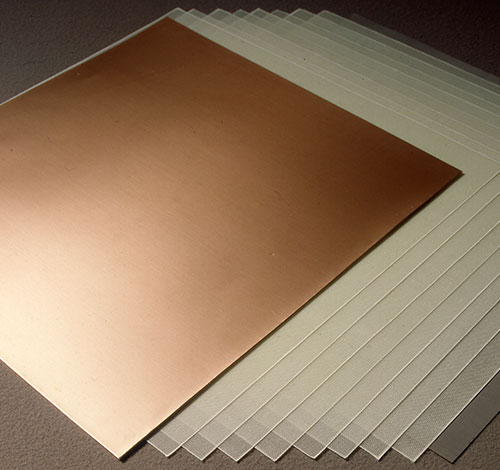

Stratifiés cuivrés (CCL)

Composants essentiels des circuits imprimés (PCB), les CCL requièrent des propriétés telles qu'une température de transition vitreuse (Tg) élevée, un module élevé, un faible coefficient de dilatation thermique (CTE), une faible constante diélectrique (Dk) et un faible facteur de dissipation (Df) pour améliorer la fiabilité de l'interconnexion et de l'installation des circuits électroniques. Les charges sont essentielles pour atteindre ces performances dans les CCL. Parmi les charges inorganiques courantes, on trouve la micropoudre de silice, le talc, l'hydroxyde d'aluminium et l'hydroxyde de magnésium. Parmi elles, la micropoudre de silice se distingue par sa grande stabilité thermique, son faible CTE et son faible Dk.

Les exigences de l'industrie CCL en matière de micropoudres de silice portent principalement sur la granulométrie, la morphologie et le traitement de surface. La granulométrie doit concilier dispersibilité et aptitude à la mise en œuvre ; théoriquement, des particules plus petites offrent de meilleurs effets de remplissage, mais des tailles trop petites peuvent entraîner une agglomération, une mauvaise dispersion et des difficultés accrues lors des processus de mélange et d'enrobage de résine. En termes de morphologie, la micropoudre de silice sphérique est privilégiée pour sa densité de tassement plus élevée, son faible CTE et sa meilleure résistance à l'usure. Le traitement de surface améliore non seulement la dispersion, mais aussi la compatibilité entre la micropoudre de silice et le système de résine.

Actuellement, la micropoudre de silice de haute pureté utilisée dans les CCL présente encore des défis, notamment la dépendance aux importations pour les produits haut de gamme, le coût relativement élevé de certaines qualités et la nécessité d'optimiser davantage les procédés de production. Les axes de développement futurs se concentreront sur la localisation des produits haut de gamme, la substitution des importations et la satisfaction des exigences spécifiques des CCL haute fréquence et haut débit.

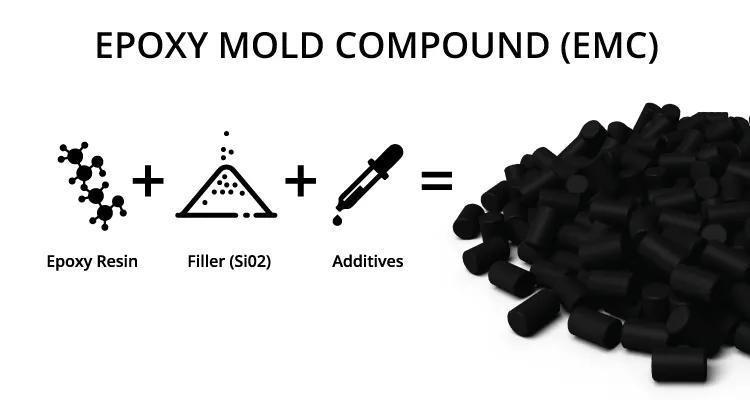

Composés de moulage époxy (EMC)

En tant que matériau d'encapsulation critique pour semi-conducteurs, les exigences de l'EMC en matière de charges portent principalement sur la réduction du CTE, l'augmentation de la conductivité thermique et la diminution du Dk. Grâce à ses excellentes propriétés physiques et chimiques, la micropoudre de silice est une charge essentielle dans les EMC, représentant généralement entre 60% et 90% du poids du composé.

L'utilisation de micropoudres de silice comme charge dans les CEM offre des avantages significatifs. Sa grande pureté et sa faible radioactivité réduisent efficacement le CDT et le retrait du composé durci, tout en améliorant la résistance mécanique et les propriétés d'isolation. De plus, comparée à la poudre de silice angulaire, la micropoudre de silice sphérique offre une densité de tassement plus élevée. Lorsque la granulométrie est comprise entre 0,1 et 30 μm, la densité de tassement peut dépasser 92%, réduisant potentiellement l'utilisation de résine époxy jusqu'à 50%. La structure sphérique offre également une excellente fluidité, ce qui non seulement réduit les défauts tels que les bavures et les bulles d'air, mais prolonge également la durée de vie du moule.

Actuellement, l'application de la micropoudre de silice dans les CEM est également confrontée à des défis. La technologie de production des produits haut de gamme présente des obstacles importants, notamment la complexité du procédé de fabrication de la silice sphérique, ce qui entraîne des coûts plus élevés. À l'avenir, avec la tendance à la performance et à la miniaturisation des boîtiers électroniques, les exigences en matière de granulométrie, de pureté et de sphéricité de la micropoudre de silice deviendront encore plus strictes.

Caoutchouc

La micropoudre de silice est utilisée comme charge fonctionnelle dans l'industrie du caoutchouc, offrant des avantages applicatifs significatifs et de vastes perspectives de développement. Les principales exigences en matière de charges pour les produits en caoutchouc portent sur l'amélioration des propriétés physico-mécaniques, de la résistance à l'usure, de la résistance à la chaleur et des performances anti-vieillissement. Grâce à sa petite granulométrie, sa grande surface spécifique, sa bonne résistance à la chaleur et à l'usure, la micropoudre de silice peut améliorer significativement la résistance à la traction, le module et la résistance au déchirement des composites de caoutchouc. De plus, sa grande pureté et sa bonne dispersibilité lui permettent de former une couche de charge uniforme au sein de la matrice de caoutchouc, améliorant ainsi la résistance à l'abrasion et au vieillissement.

Cependant, la surface de la micropoudre de silice contenant un grand nombre de groupes silanols acides, sa compatibilité avec la matrice de caoutchouc peut être médiocre, ce qui peut affecter les performances globales du composite. Actuellement, les chercheurs s'attaquent principalement à ce problème par des techniques de modification de surface, utilisant généralement des agents de couplage silane et titanate. Ces modificateurs peuvent réagir avec les groupes hydroxyles présents à la surface de la silice, réduisant ainsi son énergie de surface et améliorant ainsi la compatibilité et la dispersion au sein de la matrice de caoutchouc.

À l'avenir, face à la demande croissante de matériaux en caoutchouc haute performance, le développement de micropoudres de silice ultrafines et de haute pureté et de nouveaux modificateurs spécialisés constituera une tendance importante. Parallèlement, des recherches approfondies sur les mécanismes de modification et la manière d'optimiser les effets synergétiques des modificateurs constitueront des axes majeurs dans le domaine de la modification de surface de la silice.

Autres applications

Matériau inorganique non métallique hautes performances, la micropoudre de silice est également largement utilisée dans les revêtements, les isolants électriques et les adhésifs. Dans l'industrie des revêtements, elle améliore considérablement la résistance à la corrosion, à l'abrasion, les propriétés isolantes et la résistance aux hautes températures. L'ajustement de la granulométrie permet d'optimiser la densité du film et peut remplacer partiellement le dioxyde de titane tout en maintenant le pouvoir couvrant et en améliorant la résistance à la chaleur. Dans les matériaux isolants électriques, grâce à sa haute résistance à l'isolation et aux hautes températures, la micropoudre de silice est largement utilisée dans les isolateurs et les accessoires de câbles des équipements électriques, prévenant efficacement les fuites de courant et garantissant un fonctionnement sûr. De plus, son application dans les adhésifs et les produits d'étanchéité est en plein essor. En améliorant la force d'adhérence avec les résines et en réduisant le pic de température exothermique lors du durcissement, la micropoudre de silice améliore efficacement les propriétés mécaniques et la résistance au vieillissement des adhésifs.

Poudre épique

À Poudre épiqueNous sommes spécialisés dans la production avancée de micropoudres de silice sphériques de haute pureté, essentielles à ces applications exigeantes. Notre procédé de fabrication de pointe s'appuie sur des broyeurs à jets d'air à lit fluidisé de pointe, intégrés à des classificateurs à air de haute précision. Ce système sophistiqué est essentiel pour obtenir les qualités de produit supérieures exigées par l'industrie.

Contrôle précis de la taille des particules : Nos broyeurs à jets fournissent l'énergie mécanique intense nécessaire à une fragmentation efficace, tandis que nos classificateurs garantissent une distribution granulométrique (DSP) exceptionnellement étroite et rigoureusement contrôlée. Ceci est essentiel pour optimiser des propriétés telles que la fluidité dans les matériaux composites métalliques, la dispersion dans les revêtements et le renforcement du caoutchouc.

Traitement de haute pureté et sans contamination : Le mécanisme de broyage de nos broyeurs à jet, qui repose sur l'impact des particules dans un flux d'air haute pression, minimise la contamination par les pièces d'usure. Ceci est essentiel pour produire la micropoudre de silice de haute pureté nécessaire aux applications électroniques telles que les CCL et les CEM.

Solutions sur mesure : Nous comprenons que chaque application a des exigences spécifiques. Notre expertise technique nous permet d'adapter les paramètres de broyage et de classification afin de produire des micropoudres de silice présentant des PSD, des morphologies et des caractéristiques de surface spécifiques, accompagnant ainsi nos clients dans leur démarche d'innovation en matière de matériaux.

En maîtrisant la synergie entre fraisage au jet et la classification de l'air, Poudre épique fournit une micropoudre de silice homogène et performante qui répond aux normes rigoureuses des industries modernes, permettant à nos clients de développer des matériaux de nouvelle génération.