Introduction

Dental ceramics play a pivotal role in modern restorative dentistry. It offers a wide range of materials with aesthetic appeal, durability, and functional benefits. These materials include feldspathic porcelain, lithium disilicate, and zirconia. Each with specific requirements for particle size distribution (PSD) and uniformity in their manufacture. The precision of these materials directly influences the overall performance of dental restorations.

For manufacturers of dental ceramics, the ability to consistently produce powders with finely controlled characteristics is a critical factor. This is where advanced milling technologies, such as air jet mills, come into play. EPIC Powder Machinery specializes in providing state-of-the-art air jet milling systems that ensure the high standards of dental ceramics production are met with exceptional consistency, minimal contamination, and high processing efficiency.

This article explores the process of crushing and classification in dental ceramic production. It can focus on the role of air jet mills and how they support manufacturers in producing superior materials. It also includes industry insights and future developments for powder processing technologies.

1. Understanding Dental Ceramics and Their Applications

Dental ceramics are materials used in the fabrication of dental restorations, such as crowns, bridges, veneers, and dentures. They are favored for their excellent aesthetics and biocompatibility. The most common types of dental ceramics include:

Feldspathic Porcelain: Known for its high translucency and natural appearance, ideal for crowns and veneers.

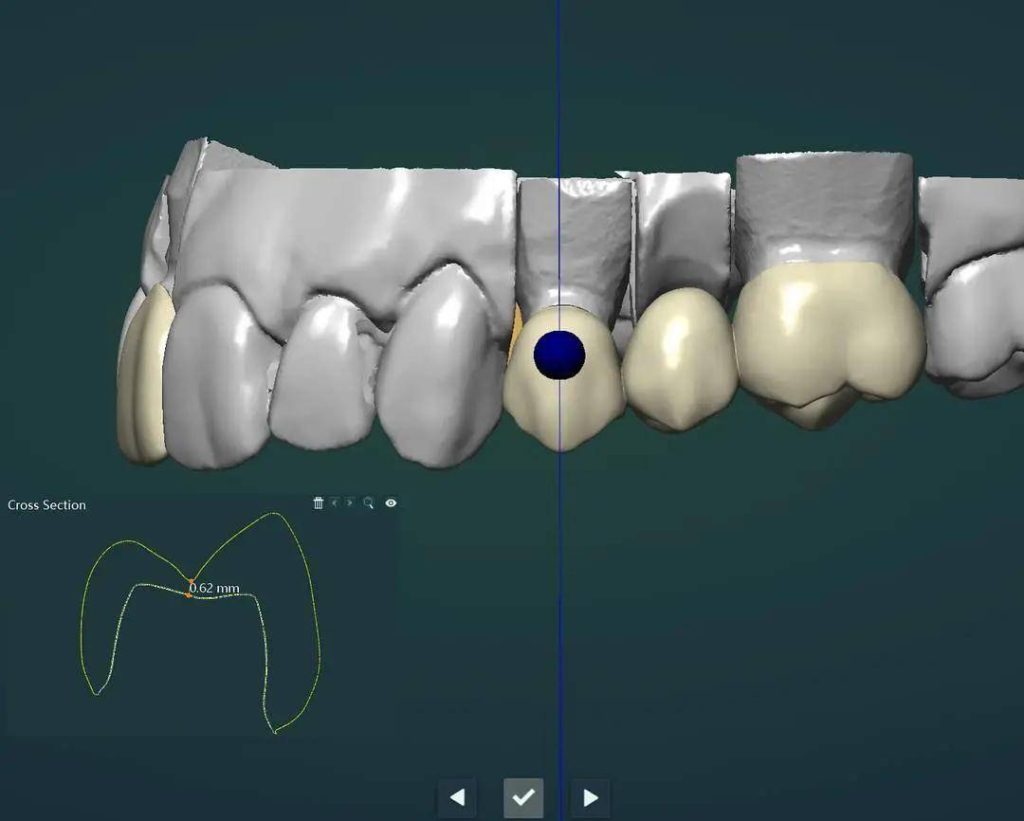

Lithium Disilicate: A high-strength material suitable for both anterior and posterior restorations. It’s known for its ability to be fabricated with CAD/CAM systems.

Zirconia: Strong and durable, zirconia is used for crowns, bridges, and implants, providing both aesthetic quality and resilience.

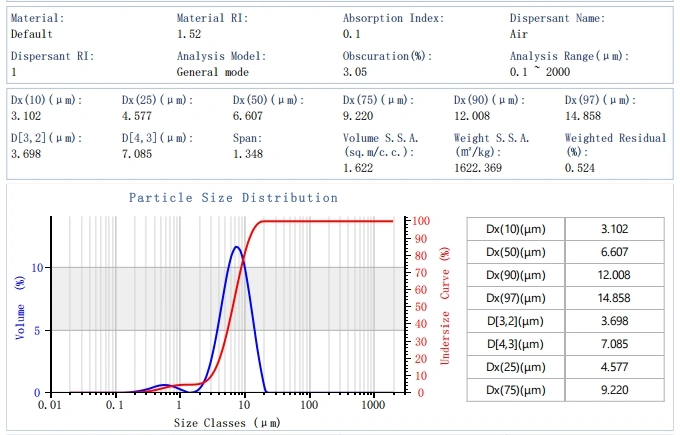

The performance of these materials is heavily influenced by their particle size distribution (PSD). For example, smaller and more uniform particles enhance the sintering process. This directly affects the material’s strength, translucency, and overall quality.

2. The Crushing and Classification Process in Ceramic Powder Production

In the production of dental ceramics, the crushing and classification of raw materials is a critical stage that ensures uniformity and consistency. Traditional grinding techniques such as ball milling or hammer milling can produce powders with varying degrees of contamination and particle size inconsistency. These issues can lead to suboptimal material properties in the final ceramic products.

Jet mills, on the other hand, utilize high-pressure air to accelerate particles and collide them, effectively reducing their size. The result is a fine, uniform powder with minimal heat generation, which is especially important when processing heat-sensitive materials like dental ceramics.

After milling, it is essential to classify the powder to remove oversized particles and ensure that the material meets the precise particle size specifications required for dental applications.

3. The Role of Jet mills in Dental Ceramic Production

Jet mills provide a controlled, efficient method for producing fine, consistent powders. Unlike traditional mills, Jet mills do not involve physical grinding surfaces, which means there is minimal contamination of the powder. This is particularly important for the production of dental ceramics. Even trace amounts of impurities can affect the material’s properties in it.

How Jet mills Work:

Jet mills use compressed air to accelerate particles to high velocities. The particles then collide with each other or with a target surface, resulting in size reduction.

The size reduction occurs due to the kinetic energy of the particles and the turbulent flow created within the milling chamber.

The air pressure and nozzle design play crucial roles in determining the efficiency of the milling process and the final particle size distribution.

EPIC Powder Machinery’s Jet mills are designed for high precision, with customizable configurations to handle a wide range of ceramic materials. Their versatility allows manufacturers to process dental ceramics efficiently, achieving uniform particle sizes and minimal contamination.

4. Data-Driven Insights on Jet mills Performance (Placeholder)

While specific data for dental ceramics is pending, the general performance of Jet mills can be summarized as follows:

Particle Size Reduction Efficiency: Jet mills are capable of reducing particle sizes down to the sub-micron level, achieving a uniform particle size distribution (PSD) that is essential for dental ceramics.

Energy Consumption: Jet mills generally require lower energy input compared to traditional grinding methods due to their efficient particle acceleration mechanisms.

Throughput: EPIC Jet mills offer scalable throughput capabilities, ensuring manufacturers can meet varying production demands without sacrificing quality.

These performance metrics, when available, will allow manufacturers to assess the suitability of Jet mills for their specific ceramic processing needs.

5. Classifying Ceramic Powders: Techniques and Challenges

Once milling is complete, the ceramic powders must undergo classification to remove oversized particles and achieve the desired particle size distribution. The classification process ensures that the powder is suitable for further processing, such as pressing or sintering, which are essential steps in the creation of dental restorations.

Air Classifiers are commonly used in conjunction with Jet mills. These devices use a controlled airflow to separate particles based on their size. This ensures that only particles within the desired range are used in the manufacturing process, minimizing waste and enhancing product quality.

The main challenge in classifying ceramic powders is maintaining a consistent PSD across different batches. Variations in air pressure, nozzle design, and classifier configuration can result in inconsistencies.

Dental ceramic powders are often very fine and can be challenging to classify effectively. Advanced air classifier systems, such as those used by EPIC, are designed to handle these fine powders with precision, ensuring high-quality results.

6. Industry Analysis: Trends in Dental Ceramics and Powder Processing

The global dental ceramics market is growing rapidly due to increasing demand for aesthetic dental restorations, advancements in CAD/CAM technology, and a growing aging population. As the demand for high-performance dental ceramics rises, manufacturers are turning to advanced milling and classification technologies to meet these requirements.

Key Industry Trends:

Shift Toward More Aesthetic Materials: There is a growing preference for materials that mimic the natural appearance of teeth, such as lithium disilicate and zirconia.

CAD/CAM Integration: The integration of CAD/CAM technology allows for more precise design and fabrication of dental restorations, which in turn demands higher quality powders.

Miniaturization of Dental Products: Smaller and more intricate restorations require finer, more uniform ceramic powders that are best produced using advanced milling technologies like Jet mills.

These trends drive the need for efficient and precise powder processing technologies, positioning Jet mills as a key solution in dental ceramics manufacturing.

7. Future Developments in Powder Processing for Dental Ceramics

As the dental industry evolves, so too must the technologies used to manufacture ceramic materials. The future of dental ceramics will likely see further developments in:

Energy Efficiency: Reducing the energy consumption of milling systems will be a key focus, as manufacturers seek to improve sustainability and lower operational costs.

Advanced Classification Systems: Future advancements in air classifiers will provide even more precise control over particle size distribution, further improving the consistency and performance of dental ceramics.

Automation: Increased automation in the milling and classification process will help manufacturers scale production while maintaining high-quality standards.

EPIC Powder Machinery continues to innovate and refine its Jet mills and classification systems to meet the ever-changing demands of the dental ceramics industry.

8. Conclusion

The production of high-quality dental ceramics requires precise control over particle size and distribution. Jet mills offers a highly effective solution for this, providing uniform powder with minimal contamination. As the dental industry continues to demand more advanced materials and technologies, EPIC Powder Machinery remains at the forefront, offering cutting-edge jet mills systems that meet the highest standards of performance and efficiency.

For manufacturers looking to improve their powder processing capabilities, Jet mills are the technology of choice. By investing in these systems, they can achieve superior results, reduce production costs, and meet the growing demands of the global dental ceramics market.