A bright, beautiful smile is often considered one of the most attractive features a person can have. To achieve flawless teeth and a confident smile, many people turn to cosmetic dentistry. Behind the scenes, advanced technology plays a crucial role in producing the high-quality materials needed for these dental procedures. Among them, Epic Powder’s jet mill stands out as an efficient solution for manufacturing ultra-fine raw material powders. The jet mill can produce dental materials that make dental products, such as glass ionomer or ceramics material. Let’s take a closer look at how this innovative technology contributes to the world of dental aesthetics.

Glass Ionomer

Composition: Acrylic acid, glass, and fluoride.

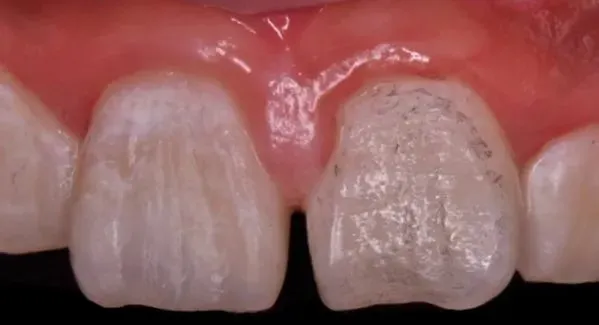

Color Characteristics: Glass ionomer has a chalky appearance and poor transparency. Traditional glass ionomer materials are not as effective as composite resins in matching the color of teeth. They are not suitable for aesthetic restoration of anterior teeth.

Sandwich Technique:

The “sandwich” technique refers to the combined restoration method that uses glass ionomer adhesive as a base material to bond to dentin. It’s followed by the use of composite resin to fill the defective enamel. This technique is also commonly known as the “sandwich technique.” The combination of these two materials can complement each other to achieve more satisfactory results. This makes it an ideal choice for dentin restoration.

Consideration of the Influence of Adhesives on Color

Resin Adhesives: Resin adhesives are available in a variety of colors and transparencies, and they are highly compatible with dentin. Light-curing adhesives and dual-curing adhesives without tertiary amines offer good color stability. Theyc’re suitable for bonding aesthetic restorations of anterior teeth. However, chemically cured resin adhesives tend to undergo significant color changes.

Non-Resin Adhesives: Generally, non-resin adhesives have poor color and transparency. As a result, the final color of the restoration can be affected after bonding. especially when the restoration has good transmittance. When bonding all-ceramic restorations with high transparency, using zinc phosphate and glass ion adhesives with poor transparency may cause the restoration’s color to change. These adhesives should be used with caution.

Composite Adhesives: Compared to resin adhesives, composite materials have higher water absorption and are more likely to cause color changes due to the absorption of colorants from the environment. Glass ion composites and resin-reinforced glass ion materials are particularly susceptible to environmental color influences, leading to poor color stability.

Finishing and Polishing: Simulating Natural Enamel Gloss and Improving Surface Finish

Establishing Macro and Micro Textures: Creating texture is an important step in finishing dental materials to simulate the natural enamel appearance.

Soften the Surface of the Material: Apply fine-grained rubber wheels or new spiral materials for this purpose.

Polishing: It is recommended to use low-grit (less than 0.5 microns) diamond polishing paste or aluminum oxide polishing paste. Also it’s along with felt wheels or soft-bristled polishing brushes, to achieve a smooth and glossy surface finish.

Polishing Effect: Proper polishing enhances the overall aesthetic quality of the restoration by mimicking the natural gloss of enamel.

EPIC Powder Machinery’s Contribution to Dental Glass Raw Materials

At EPIC Powder Machinery, we specialize in the production of high-purity glass powder and ceramic powder used as raw material in dental restorative products such as glass ionomer cements and composite adhesives. Leveraging our advanced jet milling and classification systems, we can produce ultrafine fluoroaluminosilicate glass powder with controlled particle size distribution tailored for dental applications.

Typical D50 particle size: 2–5 μm Purity: >99.5%

Glass composition: SiO₂, Al₂O₃, CaF₂, Na₂O, and P₂O₅

Our production process ensures minimal contamination, high whiteness, and narrow particle size distribution—crucial features for achieving consistency, bio-compatibility, and optimal color blending in dental material. We also offer custom solutions for R&D teams and manufacturers seeking specialized compositions or enhanced performance in their glass-based dental formulations.