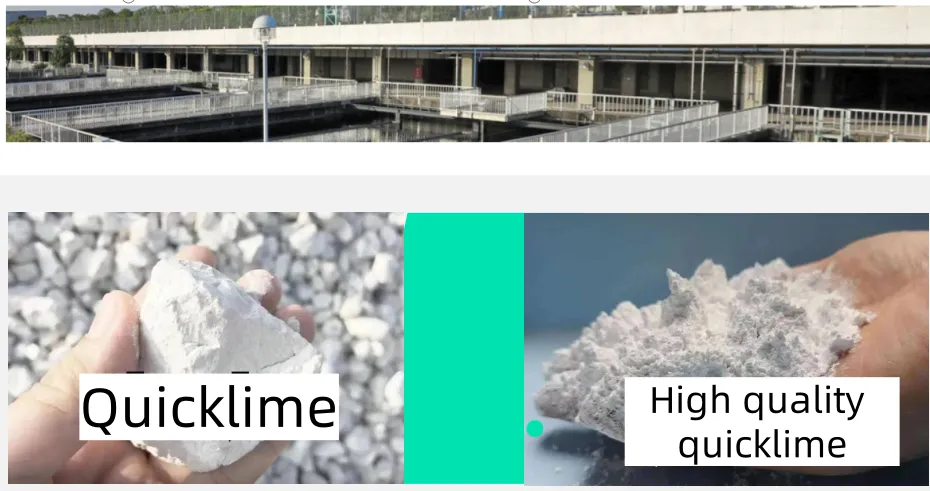

Types of Lime: Quicklime & Slaked Lime

There are two types of lime: quicklime and slaked lime. Both are made from limestone, which is collected by cutting the stone. The difference between quicklime and slaked lime lies in the processing method of limestone.

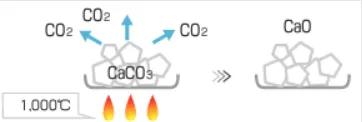

Quicklime: Chemical formula: CaO (calcium oxide)

Limestone is heated (burned) at about 1000°C, causing carbon dioxide to be released from calcium carbonate, its main component. This process produces quicklime. Quicklime is often used as a desiccant for snacks, among other products, due to its moisture-absorbing properties.

Slaked Lime

Chemical formula: Ca(OH)₂ (calcium hydroxide)

When water is added to quicklime (a process known as “slaking”), the quicklime will heat up. This is known as slaked lime. Some products, such as heating packs for bento boxes and drinks, use this process to generate heat by pulling a rope, which is based on the same principle as slaked lime.

About the Production Process of Refined and Highly Active Lime

The above explanation describes how quicklime is produced by heating limestone. Industrial lime is typically fired using coal powder, natural gas, coke oven gas, or blast furnace gas as fuel. High-purity lime products with high calcium content, high activity, and special properties are produced by using advanced firing technology. This includes the use of preheaters, rotary kilns, and vertical rapid coolers for firing limestone.

In the past, it was often fired using shells. Natural calcifications mainly exist as biomass calcium and mineral calcium. Limestone was not mined from mines but was replaced by “shell lime” made from roasted oysters and clams. (Shells are composed of calcium carbonate, which, when roasted, produces lime.) About 420 years ago, the Hemudu people first discovered the method of firing shell lime. Today, with the emphasis on resource reuse, shell lime is widely used, primarily as mineral calcium.

Changing Fuel from Charcoal to Coal

Historical records show that it wasn’t until the Song Dynasty that a revolutionary improvement was made in the use of coal, which occurred hundreds of years earlier than in Europe. According to the verifiable document “The Exploitation of the Works of Nature”, many manual industries in the Ming Dynasty used coal cakes. When burning lime, “the ash and firewood accounted for 19% of coal and 11% of firewood. First, take coal mud and make coal cakes. For each coal cake, a layer of stone is stacked on top, and firewood is spread on the bottom, then burned with fire.” This method involved alternately stacking layers of coal and stone, with firewood spread at the bottom to ignite the fire.

At that time, the strategy among lime manufacturers was to “replace charcoal with coal as the fuel for lime burning.” The furnace temperature when using charcoal was limited to 800°C, while coal could reach up to 1200°C, greatly improving efficiency and enabling mass production. However, this strategy was initially unsuccessful. The most difficult part of the transition from charcoal to coal was reconstructing the furnace. The furnaces that had been used could not withstand the higher temperature of 1200°C.

The breakthrough came with the construction of a new furnace, 7.5 meters deep and 0.9 meters in diameter, with the help of a wealthy merchant. This lime-burning furnace, known as the “sake pot type,” had a varying diameter. The maximum diameter of the central part was 1.65 meters. In comparison, the previous charcoal furnace had a depth of only 1.5 meters and a diameter of 0.84 meters, clearly showing a significant difference in furnace capacity. Additionally, salt was added during the process.

Wide Range of Uses of Lime

When you think of “lime,” you might envision white lines and chalk on a sports court. Additionally, some might associate it with marble used on the floors and walls of large facilities, such as hotels. In reality, it is used extensively in many aspects of our lives. Here’s an introduction to its wide range of applications in fields like civil engineering, steel, chemicals, food, medicine, water treatment, and pollution prevention.

Uses in Medicine and Reagents

Calcium tablets, injections, powders, dental materials, artificial bones, surgical fixation bandages (plaster), etc.

Calcium compounds are used in many pharmaceuticals, not only as calcium and phosphorus supplements but also as components in injections and oral medicines. Additionally, lime is used in surface coatings for metal materials and in tablets for biological applications.

Chemical Industry Uses

Glass, ceramics, soda, bleach, carbide, pulp, seawater magnesium, metal magnesium, petrochemicals, toothpaste, rubber products, etc.

The chemical industry refers to the sector that processes raw materials through chemical reactions to create products. Processed products that we encounter daily, such as household items, office supplies, electrical appliances, and glass products, are all made through the chemical industry. The chemical industry, which forms the backbone of our society and supports cultural life, would not be possible without it.

Marble, Gypsum, Plaster, Sanwa Clay, etc.

The main component of these building materials is lime. Marble was used in ancient structures like the Egyptian pyramids and the Greek Parthenon, and today, it is still used for interior and exterior decoration in buildings. Plaster (also known as “plaster of Paris”) and Sanwa clay (used in hammered masonry) are also important materials in traditional Japanese architecture, such as castles, where they have a long historical use.

Smoke Desulfurization

The exhaust gases produced by burning large amounts of oil and coal in thermal power plants, waste incineration facilities, steel mills, etc., contain harmful substances such as hydrogen chloride and sulfur oxides. These toxic gases not only have adverse effects on human health but also contribute to “acid rain,” which causes forests to wither. Lime is used to remove these toxic gases effectively.

Food Uses

Konjac, sugar, tofu, chewing gum, starch syrup, bread, fish cakes, sausages, seasonings, agar, etc.

The main component of lime is calcium. Calcium, which is often lacking in our diet, has recently been added to many foods.

It is used in a variety of ways, such as in the coagulation of konjac, removal of impurities during sugar refining, as a neutralizer in starch syrup, as a preservative and emulsifier in bread, and for enhancing the texture of fish cakes and sausages. Additionally, calcium lactate and calcium phosphate are added to refreshing drinks.

Lime products are also used in food warmers (for sake, bento boxes, delicious food, heated oden, etc.), which generate heat through the reaction of it with water. It is also used in food desiccants and moisture absorbers due to its moisture-absorbing properties.

Iron and Steel Production

Our daily lives are surrounded by many steel products, including cars, trains, airplanes, roads, bridges, etc. Lime plays a crucial role in the iron and steel production process.

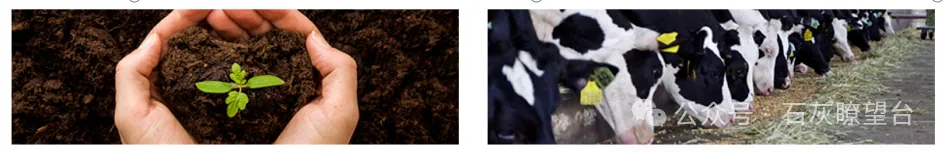

Uses in Agriculture and Livestock

The four essential elements in fertilizers are nitrogen, phosphorus, potassium, and calcium. Lime is used in various applications, including fertilizers, livestock manure treatment, pesticides, feed for laying hens and dairy cows, and the prevention of infectious diseases like avian influenza.Lime-based fertilizers provide crops with essential minerals like calcium and magnesium and help promote the decomposition of organic matter in the soil. It also neutralizes and improves acidic soils.

In the livestock industry, lime is used to adjust the water content and sterilize livestock manure, which is then recycled as nitrogen and calcium fertilizer. Lime is also used in the production of Bordeaux mixture, a pesticide with more than 100 years of history. Additionally, calcium, the main component of lime, is added to animal feed to ensure healthy livestock. Recently, lime’s sterilizing properties have been used to prevent viral infectious diseases such as avian influenza.

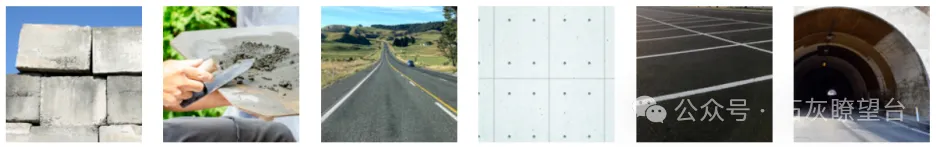

Civil Engineering Applications

Cement, concrete, aggregates, asphalt, soil stabilization, static crushers, etc.

Cement concrete is a vital material in civil engineering, and lime plays an essential role in manufacturing it. Lime is also used in soil stabilization to improve soft, waterlogged soils, turning them into strong, durable ground. It is applied in foundation engineering for roads, buildings, landfills, and airport runways.

A rare application of lime is in the use of static crushers. When old concrete buildings or rocks need to be demolished, explosives often create flying debris, noise, and vibrations. These can be hazardous. A static crusher, which uses the expansion properties of lime when it reacts with water, safely crushes concrete and rocks without the risk of explosions.

Water Treatment Applications

Lime can be used in water treatment, sewage treatment, wastewater treatment, anti-wastewater treatment, sludge treatment, etc.

Water treatment plants purify water extracted from rivers, lakes, groundwater, and other sources into safe drinking water, which is then delivered to households.

In this purification process, lime is used for pH adjustment, prevention of red water, and sludge treatment.

Sewage treatment plants use lime as a flocculant to precipitate and separate sludge. These precipitates are deodorized and sterilized by lime and are transformed into compost.

Harmful heavy metals in factory wastewater are precipitated by lime, which helps recover dissolved heavy metals as hydroxides. Additionally, lime is used to neutralize acidic wastewater.

In rivers, lakes, coastal waters, and agricultural areas where sludge has accumulated, nutrients (such as pollutants) dissolve and contribute to the formation of red tides and green tides. By spreading lime in these waters, the decomposition of organic matter is promoted. The fixation of phosphorus and heavy metals is enhanced. Lime also prevents the generation of hydrogen sulfide and helps maintain an alkaline environment, which helps prevent the occurrence of red and green tides.

Epic Powder Machinery

At Epic Powder Machinery, we specialize in providing advanced jet mill solutions for efficient processing of lime and other minerals. Our innovative equipment ensures optimal particle size reduction, enhancing the quality and performance in various industries, from water treatment to manufacturing. With decades of expertise and a commitment to precision, Epic Powder Machinery continues to support industries worldwide in achieving high standards.