In this article let’s unlock the full potential of your kaolin. Discover how مسحوق ملحمي Machinery’s Air Jet Mills deliver contamination-free, precisely controlled powder. Request a free test grind today!

Kaolin, especially in its calcined form, is a cornerstone of modern industry. Its unique properties make it indispensable for enhancing the opacity, strength, and finish in products ranging from high-gloss paints and robust plastics to advanced technical ceramics. However, unlocking this full potential presents a significant challenge for processors: how to achieve ultra-fine particle sizes without compromising the material’s inherent brightness and purity. Traditional mechanical milling methods often introduce metallic contamination, generate excessive heat, and lack the precision for consistent results.

The solution is technology engineered for these exacting standards. At Epic Powder Machinery, we specialize in harnessing the power of Air مطحنة نفاثة technology to transform your kaolin processing, delivering unparalleled purity, precise particle size control, and ultimate performance.

The Critical Link Between Grinding and End-Product Performance

In the world of high-value kaolin, the grinding process is not just about size reduction; it’s a critical determinant of the final product’s value and functionality.

Brightness and Purity are Paramount: Any iron or other metallic contamination introduced during milling can significantly diminish kaolin’s natural whiteness, directly impacting the visual appeal and quality of white or light-colored end-products.

Particle Size Dictates Performance:

◦In Coatings, a fine and tightly controlled particle size distribution is crucial for superior hiding power, gloss control, suspension stability, and film smoothness.

◦ In البلاستيك, it influences mechanical properties like impact strength and tensile modulus, as well as surface finish.

◦ In Advanced Ceramics, even minor inconsistencies or contamination can drastically affect sintering behavior and the final component’s structural integrity.

Only the cleanest and most precise grinding technology can preserve and enhance these critical properties, turning raw kaolin into a high-performance ingredient.

How Air Jet Mills Achieve Contamination-Free Kaolin Grinding

An Air Jet Mill operates on a fundamentally different principle than mechanical mills, making it ideally suited for high-purity minerals like kaolin.

The process is elegantly simple yet highly effective:

1. Acceleration: The kaolin feed material is introduced into a grinding chamber where it is entrained in multiple streams of superheated steam or compressed air, accelerated to supersonic speeds through precisely angled nozzles.

2. Comminution: Particle-on-particle impact and attrition occur at the intersection of these high-velocity streams. This self-grinding mechanism is the key to product purity.

3. Classification: The finely ground particles are carried by the airflow to an integrated dynamic classifier. A high-precision rotating turbine acts as a gatekeeper, allowing only particles that have reached the target fineness to pass. Oversized particles are recirculated for further grinding.

This design delivers inherent advantages:

No Moving Parts in Contact: The absence of rotors, rotors, or grinding media eliminates a primary source of wear and iron contamination.

Inert Grinding Environment: The use of air or steam ensures no chemical contamination occurs.

Cool Operation: The expansion of gas in the chamber creates a cooling effect, protecting the physical and chemical structure of heat-sensitive materials like calcined kaolin.

5 Strategic Benefits of Air Jet Milling for Kaolin

Investing in an Epic Powder Air Jet Mill translates into direct, measurable advantages for your kaolin production and product quality.

1. Guaranteed Maximum Product Purity & Brightness

Our jet mills provide the only true guarantee of an iron-free process. This is non-negotiable for producing high-grade kaolin that meets the stringent brightness standards of the paint, plastic, and ceramic industries.

2. Exceptional Particle Size Control and Uniformity

The integrated dynamic classifier allows for precise adjustment of the final product’s top cut and median particle size. This results in a narrow particle size distribution, ensuring consistent performance and reliability in your customers’ formulations.

3. Versatility for Both Standard and Calcined Kaolin

Whether you are processing soft water-washed kaolin or the highly abrasive calcined kaolin, our robust jet mill designs are up to the task. They efficiently handle both, providing the flexibility to produce a wide range of products without cross-contamination concerns.

4. Low Maintenance and Unmatched Reliability

With no grinding elements subject to direct wear, maintenance demands are drastically reduced compared to ball mills or roller mills. This translates to higher operational uptime, lower spare parts costs, and greater overall productivity.

5. Scalable Solutions from R&D to Full Production

Epic Powder offers a complete range of jet mills, from laboratory-sized units for product development and small-batch production to large-scale industrial systems. This ensures a seamless scale-up of your proven processes.

Proven Performance in Kaolin Processing

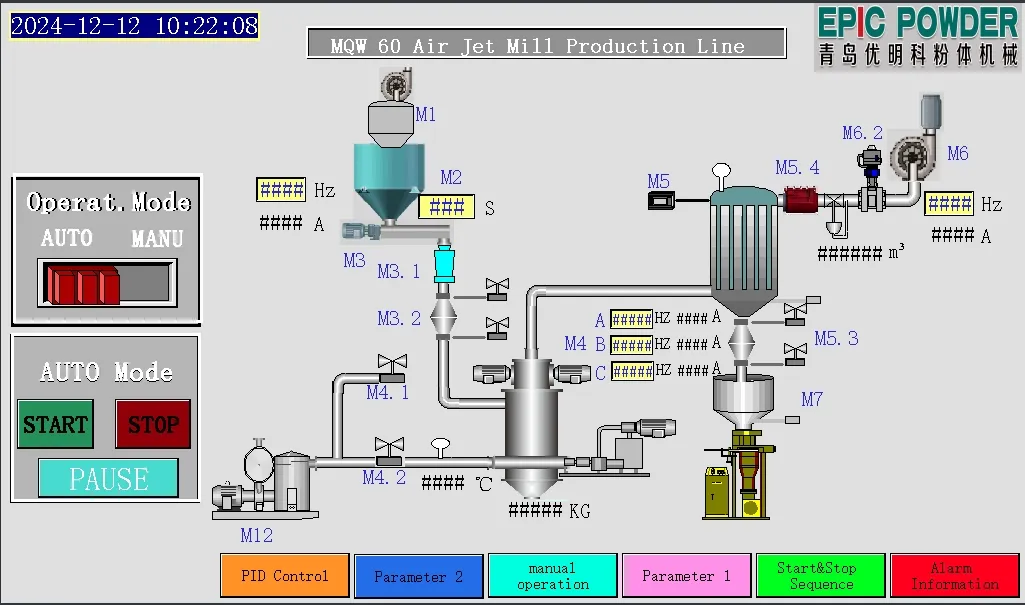

The strategic benefits outlined above are not just theoretical. They are proven in the consistent performance of our MQW Jet Mill series, as demonstrated by the following operational data for kaolin processing:

Performance Data: Jet Milling Kaolin from 400 Mesh Feed

| Model | Feed Size (Mesh) | Output Fineness (D50) | Air Pressure Consumption (m³/min) | Typical Output Capacity (kg/h) |

|---|---|---|---|---|

| MQW20 | 400 | 2.02 µm | 20 | 135 |

| MQW30 | 400 | 2.10 µm | 30 | 220 |

| MQW45 | 400 | 1.95 µm | 45 | 380 |

| MQW60 | 400 | 2.15 µm | 60 | 550 |

Note: Capacity can vary based on material characteristics and specific energy input. Data obtained under standard test conditions.

As the data shows, our jet mills are engineered to deliver repeatable results, batch after batch. This reliability, combined with the inherent advantages of contamination-free grinding, makes Epic Powder Machinery the ideal partner for your most demanding kaolin projects.

Your Partner in Advanced Kaolin Processing

At Epic Powder Machinery, we understand that your success depends on more than just a machine—it depends on a reliable partnership. Our commitment extends far beyond delivery:

Application Expertise: Our team possesses deep knowledge in mineral processing, offering you tailored solutions that optimize your specific kaolin grind for your target market.

Test and Validation Center: The best way to prove the value is to see it for yourself. We invite you to send us your kaolin samples for a free test grinding in our state-of-the-art facility. You will receive a detailed report on the achievable fineness, particle distribution, and final product characteristics.

Customized Engineering: We work with you to configure a system that matches your raw material input and production goals, ensuring optimal ROI.

Global Support Network: From installation and commissioning to ongoing maintenance and spare parts, our global network ensures you have expert support wherever you are.

Ready to achieve a new standard in kaolin quality and open doors to premium markets?

Contact Epic Powder Machinery today to schedule your free test grind and receive a professional proposal. Let us demonstrate how our Air Jet Mill technology can become your most powerful competitive advantage.

مسحوق ملحمي

In the competitive landscape of industrial minerals, the ability to produce a consistently pure, ultra-fine kaolin powder is a decisive differentiator. Air الطحن النفاث is no longer a niche technology but a strategic necessity for processors targeting high-value applications. By partnering with مسحوق ملحمي Machinery, you are not just investing in equipment; you are investing in a future of enhanced product quality, increased operational efficiency, and sustainable growth for your business.

شكرًا لقراءتكم. آمل أن يكون مقالي مفيدًا. يُرجى ترك تعليق أدناه. يمكنك أيضًا اتصل بـ EPIC Powder online customer representative Zelda for any further inquiries.”

— Posted by Jason Wang, مهندس أول