مطاحن نفاثة الهواء، وضواغط الهواء، و أسرة مميعة تُعدّ مكونات أساسية في مختلف العمليات الصناعية. ويُعد تفاعلها أساسيًا لتحقيق كفاءة في تقليل حجم المواد وتصنيفها ومعالجتها.

مطاحن نفث الهواء وضواغط الهواء

1. مبدأ عمل مطاحن نفث الهواء

تستخدم مطاحن نفث الهواء نفثات غاز مضغوطة تفوق سرعة الصوت لتحقيق طحن فائق الدقة من خلال تصادم الجسيمات، والاحتكاك، والقص. تُغذى المادة في حجرة الطحن، حيث تُسرّع تيارات الهواء عالية السرعة الجسيمات، مما يؤدي إلى تصادمها وتفككها. ثم ينقل تيار الهواء المادة المطحونة إلى منطقة التصنيف. تفصل قوة الطرد المركزي الجسيمات الأكثر خشونة، وتعيدها إلى حجرة الطحن لمزيد من تصغير الحجم. في هذه الأثناء، ينقل النظام المسحوق الذي يلبي متطلبات حجم الجسيمات عبر أنابيب التفريغ للتجميع أو التصنيف الإضافي.

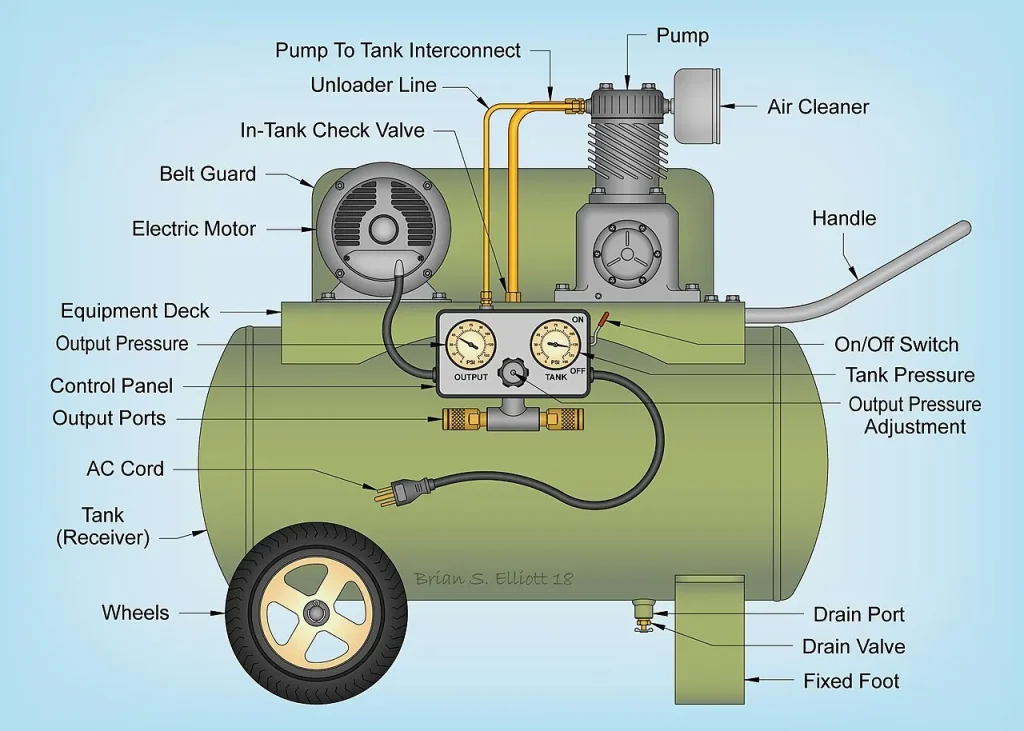

2. دور ضاغط الهواء في طحن نفث الهواء

يوفر ضاغط الهواء غازًا عالي الضغط ضروريًا لتشغيل طاحونة نفاثةيُمدّد هذا الغاز المضغوط عبر فوهات لتوليد نفثات تفوق سرعة الصوت، تُزوّد الجسيمات بالطاقة الحركية، مما يُسهّل عملية الطحن. يعمل الضاغط من خلال عمليات تشمل السحب والضغط والتفريغ، مُزوّدًا الطاحونة بإمدادات ثابتة من الهواء عالي الضغط.

الأسِرّة المميعة ومطاحن نفث الهواء

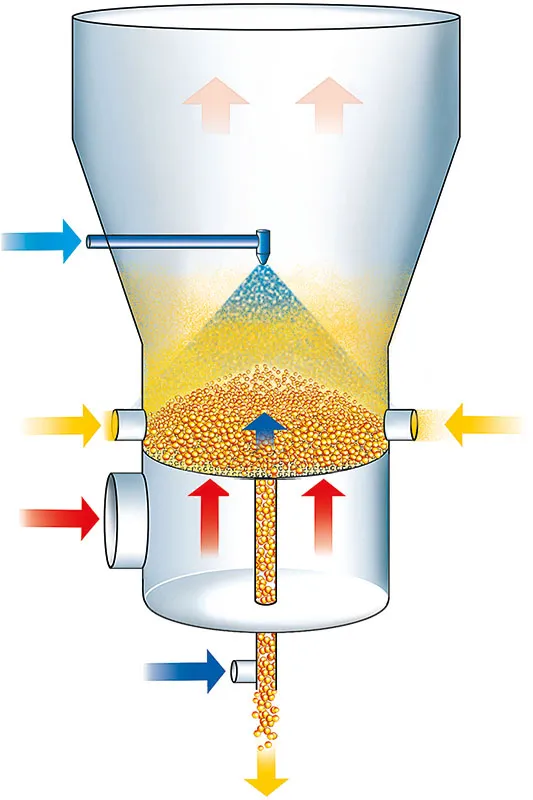

1. مبدأ عمل الأسِرّة المميعة

تتكون الطبقة المميعة من جسيمات صلبة مثبتة على صفيحة توزيع مثقبة يمر عبرها الغاز صعودًا. عندما يصل تدفق الغاز إلى سرعة حرجة، تُعلق طبقة المواد الصلبة وتُظهر سلوكًا شبيهًا بالمائع. تُعزز هذه الحالة الخلط، ونقل الحرارة، ونقل الكتلة، وكفاءة التفاعل. وهذا ما يجعل الطبقات المميعة مثالية لمختلف عمليات التجفيف، والطلاء، والاحتراق، والتفاعلات الكيميائية.

2. العلاقة بين الأسِرّة المميعة ومطاحن نفث الهواء

على الرغم من اختلاف مبادئ عمل الأسِرّة المميعة ومطاحن النفث، إلا أنه يمكن دمجهما في مراحل عملية متكاملة. على سبيل المثال، يمكن معالجة المواد مسبقًا في أسِرّة مميعة لتحسين التشتت وإزالة التكتل قبل تغذيتها في مطحنة نفث هواء لطحن فائق الدقة. يمكن أن يعزز هذا المزيج كفاءة الطحن الإجمالية وجودة المنتج.

العلاقة بين ضواغط الهواء والأسرة المميعة

من الناحية الوظيفية، لا يستخدم المشغلون ضواغط الهواء مباشرةً في عمليات الأحواض المميعة التقليدية. ومع ذلك، في التطبيقات التي تتطلب فيها العمليات مصدر غاز لتمييع الجسيمات الصلبة - كما هو الحال في النقل الهوائي أو أنواع معينة من مفاعلات الأحواض المميعة - يمكن للمصنّعين استخدام الضواغط كمصدر للغاز. في هذه الحالات، يوفر الضاغط تدفق الغاز والضغط اللازمين لتحقيق الميوعة والحفاظ عليها.

باختصار، تُحدد العمليات الصناعية العلاقة بين مطاحن نفث الهواء، وضواغط الهواء، والطبقات المميعة من خلال وظائفها الفردية وتطبيقاتها التآزرية. يوفر ضاغط الهواء غازًا عالي الضغط لتشغيل آلية طحن مطحنة النفاثة، بينما يمكن للمشغلين استخدام الطبقة المميعة كعملية تحضيرية أو مساعدة لتحسين كفاءة الطحن.

آلات مسحوق ملحمة

آلات مسحوق ملحمة شركة رائدة في مجال تصنيع وابتكار معدات معالجة المساحيق، متخصصة في مطاحن نفث الهواء، وأجهزة التصنيف، وتكامل الأنظمة ذات الصلة. بتركيزها القوي على البحث والتطوير، تقدم الشركة حلولاً متطورة، موفرة للطاقة، وموثوقة، مصممة خصيصاً لتلبية احتياجات الصناعات الكيميائية والدوائية والمعادن والمواد الجديدة.

تتميز معداتنا بالدقة والمتانة والقدرة على إنتاج مساحيق بتوزيعات جسيمات دقيقة. من خلال تقديم دعم فني شامل وأنظمة مصممة خصيصًا، تساعد شركة Epic Powder Machinery عملاءها على تحقيق جودة منتجات فائقة وكفاءة تشغيلية في عمليات الطحن والتصنيف.