In recent years, fierce market competition has driven companies to seek optimal solutions for cost reduction and efficiency improvement. Achieving technical cost reduction through filler compounding technology has become a mainstream strategy in the coatings industry. Therefore, the selection of powders is a crucial issue. Today, we will begin our analysis from the perspective of the mineral powders themselves.

In coating systems, film transparency is a core performance indicator that directly determines the visual appeal and application suitability of the coating. Its optical essence is governed by the refractive index matching between the resin binder and inorganic mineral fillers. When the refractive index difference between the filler and the resin meets |Δn| ≤ 0.03, a highly transparent system with light transmittance >90% and haze <5% can be achieved. Conversely, when |Δn| > 0.1, interface reflection intensifies, leading to significant whitening and a sharp increase in haze.

I. Powder Characteristics

A. Refractive Index Matching

The difference in refractive index between the powder and the resin binder directly affects the transparency of the composite material. When the refractive index difference between the two is less than 0.03 (e.g., the refractive index of transparent powder is approximately 1.54, close to that of resin), interface light scattering can decrease, achieving high transparency or high light transmittance. Selecting the appropriate mineral based on the refractive index of the resin system can result in better transparency or hiding power.

| Resin Type | معامل الانكسار |

| PMMA | 1.49 |

| PS | 1.59 |

| PC | 1.58 |

| Epoxy Resin | 1.55-1.60 |

| Material | معامل الانكسار |

| هواء | 1.00 |

| Water | 1.33 |

| التلك | 1.49 |

| كربونات الكالسيوم | 1.63 |

| كبريتات الباريوم | 1.64 |

| Lithopone | 1.84 |

| Transparent Powder | 1.54 |

| ثاني أكسيد السيليكون | 1.41-1.49 |

| ثاني أكسيد التيتانيوم | 2.55-2.71 |

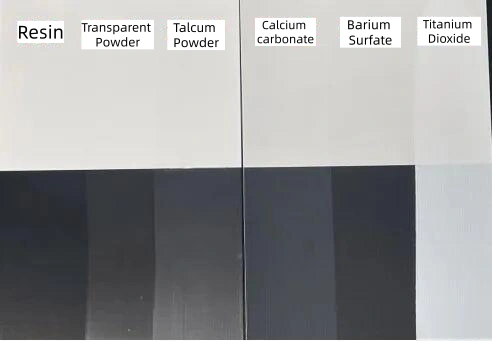

Transparency Differences of Different Mineral Powders in Acrylic Paint (Cardstock)

| Resin Solution | Transparent Powder | بودرة التلك | كربونات الكالسيوم | كبريتات الباريوم | ثاني أكسيد التيتانيوم | |

| L-value (Black Background) | 29.22 | 29.87 | 31.89 | 33.12 | 30.99 | 91.76 |

Note: The paint film was drawn down on black cardstock and the L-value was measured. A lower value indicates better transparency.

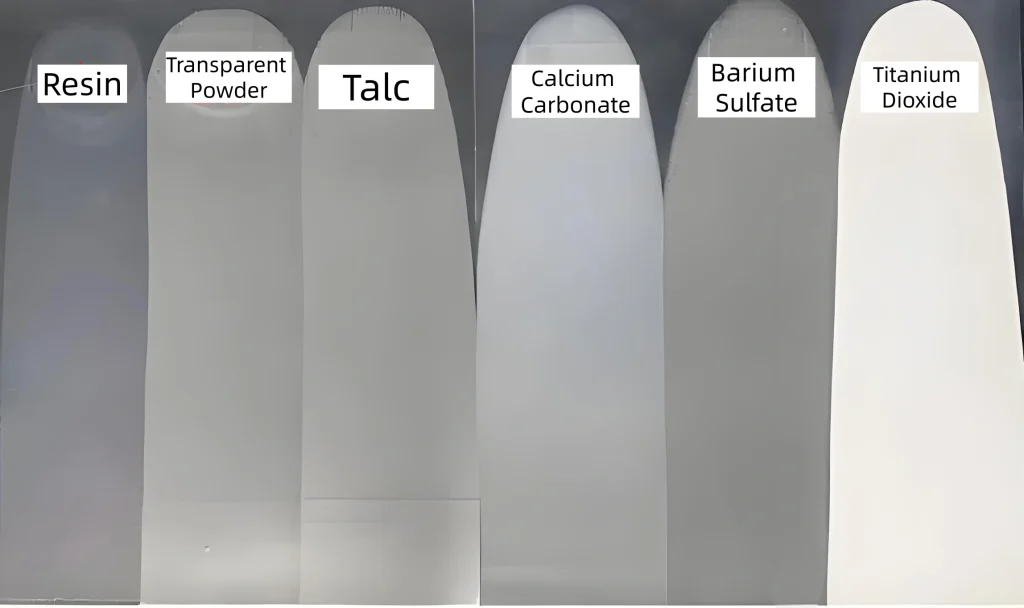

Transparency Differences of Different Mineral Powders in Acrylic Paint (Thin Film)

| Resin Solution | Transparent Powder | التلك | كربونات الكالسيوم | كبريتات الباريوم | ثاني أكسيد التيتانيوم | |

| Light Transmittance (%) | 94.85 | 93.90 | 92.40 | 90.21 | 92.91 | 18.46 |

| Image Clarity (%) | 99.41 | 12.64 | 13.49 | 7.77 | 10.52 | 9.17 |

II. Optimal Mineral Source Selection

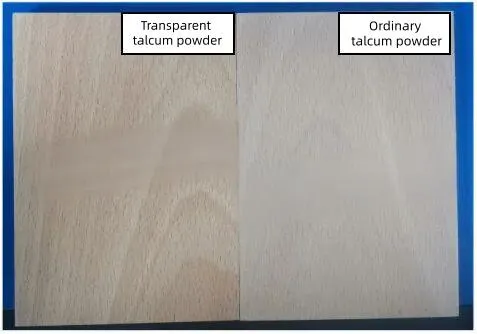

Even for the same mineral, samples from different origins can exhibit significant differences in transparency. Reasons include the formation environment, impurity content, and subsequent geological processes. Trace elements or inclusions may be mixed in during mineral formation; the stability of the formation environment also affects the crystal structure; and whether the mineral underwent geological changes that altered its internal structure.

From this perspective, selecting a powder from a high-quality mineral source in coatings can make the advantage in transparency more pronounced. Our company’s Transparent Talc series is processed from selected premium mineral sources. At the same addition ratio, overall transparency and clarity are significantly improved. When used in water-based wood coatings, the finished product exhibits clear wood grain, a smooth surface, and maintains good sandability.

III. Limitations and Potential Issues: Negative Impact of Hardness on Sandability

Most transparent fillers have high hardness. For example, although silicon dioxide (especially crystalline quartz) is a transparent mineral, its Mohs hardness is about 7, classifying it as a high-hardness mineral filler. When added to coatings, while it can improve film transparency, it significantly increases sanding difficulty, leading to reduced sanding efficiency or compromised surface smoothness, and increases the consumption of sanding consumables like sandpaper. Furthermore, high-hardness powders can also cause wear and tear on coating production equipment (such as mixer blades).

نبذة عن شركة Epic Powder Machinery

آلات مسحوق ملحمة is a leading company specializing in the research, development, and manufacturing of advanced powder processing equipment. We provide comprehensive solutions for size reduction, classification, modification, and coating of various industrial powders, including minerals, chemicals, and pharmaceuticals. If you’re interested,lml feel free to اتصل بنا and learn more about our products.