Strategic emerging industries are almost all related to non-metallic minerals and their products. In particular, graphite, fluorspar, pyrophyllite, quartz, these products play an irreplaceable and vital supporting role in new materials. Moinho a jato pulverization has emerged as a critical enabling technology, providing the necessary precision and purity in particle size reduction to unlock the full potential of quartz, graphite, fluorite, and pyrophyllite in their respective high-tech applications.

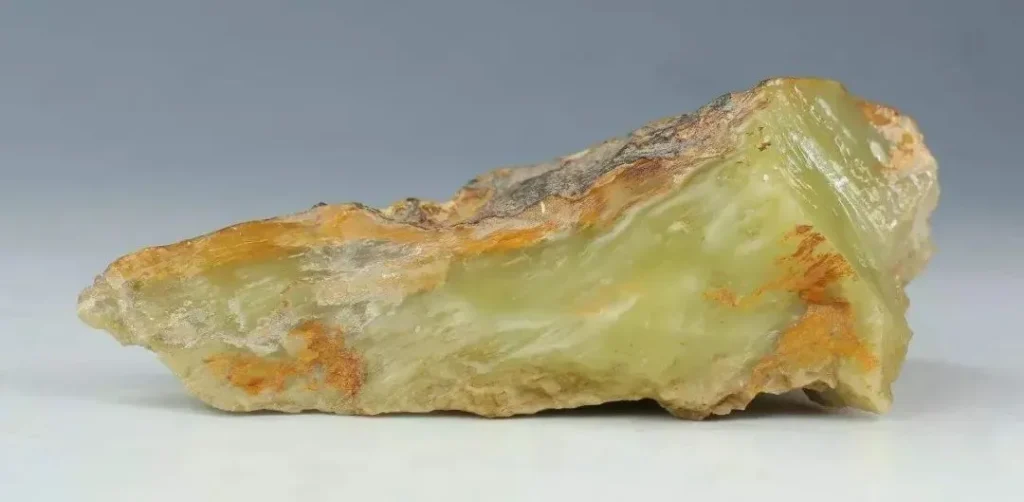

High-Purity Quartz

High-purity quartz has excellent physicochemical properties. It primarily serves the quartz glass and integrated circuit industries. Its high-end products find wide application in next-generation Informação technology, high-end equipment manufacturing, and new materials. Since World War II, manufacturers have used quartz to produce electronic components for communication phones and military radios. Globally recognized high-purity quartz raw materials are essential foundations for today’s high-tech products. They are necessary for a country’s sustainable development of high technology. In Germany, ultra-high-purity quartz materials have been classified as strategic resources, thus limiting their export.

The demand for high-purity quartz materials will significantly influence the core electronic industries, intelligent manufacturing equipment, advanced inorganic non-metallic materials, high-performance fibers and products, composite materials, cutting-edge new materials, and industries like wind and solar energy, as well as energy-efficient industries.

(1) Applications of High-Purity Quartz in Strategic Emerging Industries

New Generation Information Technology: High-performance quartz glass products are mainly used to produce single-mode and multi-mode optical fiber preform rods and quartz tubes for integrated circuits, semiconductor chips, and information display glass.

High-End Equipment Manufacturing: Used in microscopic optical instruments, optical lenses, and quartz lamps.

New Materials: Quartz fibers can be used to manufacture rocket nozzles, aerospace thermal protection devices, etc. Electronic-grade silicon micropowder is mainly used for encapsulation and packaging materials in integrated circuits and electronic components.

New Energy: Crystalline silicon materials are used to produce solar cells.

(2) Current Status and Future Development Trends of the High-Purity Quartz Industry

China is a major producer and consumer of high-purity quartz. It is self-sufficient in mid to low-end products, exporting some, while still relying on imports for high-end products. In the future, high-purity quartz sand will have broad application prospects in strategic emerging industries such as fiber optic cables, electronic communications semiconductors, LED lighting manufacturing packaging, and new energy solar applications, with demand projected to grow at a rate of about 10.0%-14.0% from 2019 to 2030.

The pursuit of higher purity is a central theme in the quartz industry. To meet the stringent requirements of high-tech applications, advanced processing technologies like jet mill pulverization are indispensable. This method provides a contamination-free way to produce ultra-fine quartz powders with consistent particle size distribution, which is critical for manufacturing high-performance quartz glass used in semiconductors and fiber optics. The adoption of such precise grinding techniques is key to upgrading product quality and competing in the global high-purity quartz market.

2. Graphite

Graphite has always been an indispensable strategic resource for military and modern industrial development. It serves the new energy vehicle industry primarily in producing lithium-ion battery anode materials, new power batteries, and supercapacitors. In the new energy sector, it enables solar cells and batteries for wind power storage. The high-end equipment manufacturing industry uses it for sealing materials and neutron moderators, while the new-generation information technology sector applies it in high-capacity energy storage and key electronic materials. The development of graphene elevates graphite’s utility to new heights. Moving forward, graphite and its products will see extensive use in aerospace satellites, smartphones, tablets, hybrid vehicles, electric cars, and solar cells, establishing their role as strategic emerging materials.

(1) Applications of Graphite in Strategic Emerging Industries

High-End Equipment Manufacturing: Used as a neutron moderator and protective material in atomic bomb reactors. Flexible graphite is used for sealing in atomic energy valves; it is also used to manufacture nozzles for solid fuel rockets, missile nose cones, parts of space travel equipment, thermal insulation materials, and radiation protection materials. Radio links and conductive structural materials on artificial satellites.

New Energy: High-temperature gas-cooled fuel matrix materials for nuclear energy require 64% natural flake graphite. Its excellent conductivity allows it to be made into solar cells and energy storage batteries for wind power generation, contributing to clean energy sectors and saving energy consumption.

New Energy Vehicles: Natural graphite anode materials are key raw materials for lithium-ion batteries, using natural graphite to produce lithium-ion batteries, new power batteries, and supercapacitors for hybrid vehicles, electric vehicles, and solar vehicles.

In next-generation IT, graphite lithium batteries power communication base stations, laptops, and phone chargers. Graphene supercapacitors deliver essential energy storage for telecom and data networks, while also enabling the creation of foldable displays. Looking ahead, graphene could revolutionize computer chips, potentially boosting processor speeds by hundreds of times. It will pave the way for the next generation of supercomputers.

New Materials: Functional fillers in new coatings and inks are mainly applied in marine and chemical industries, including graphene heavy-duty anti-corrosion coatings. Graphene water-based inorganic coatings; next-generation graphene inorganic powder coatings; graphene thermal conductive coatings for non-stick cookware and LED fixtures.

Energy Conservation and Environmental Protection: Wastewater treatment, radioactive waste cleanup, etc.

Biology: Medical disinfectants, chemotherapy drugs, DNA sequencing, artificial muscles, and food packaging.

(2) Current Status and Future Development Trends of the Graphite Industry

Graphite is a strategic mineral in China. It has the potential to influence and change the global supply. However, there is an excess of primary product capacity and insufficient supply of high-end products. In the future, demand for graphite in traditional fields will remain stable, while emerging industries will see rapid growth in graphite demand, primarily driven by crystalline graphite.

By 2030, graphite demand is expected to reach 1.348 million tons, with the new energy sector accounting for 50.4%. Therefore, it is essential to strengthen mining resource management while improving the deep processing technology of graphite to gradually develop graphite products toward high-end applications, meeting the needs of strategic emerging industries and increasing international influence.

Jet mill pulverization is particularly effective in processing flake graphite. It can delaminate and refine the flakes without damaging their crystalline structure, thereby preserving their crucial electrical and thermal properties. This makes it an ideal technology for producing high-quality anode materials for lithium-ion batteries and conductive additives, which are essential for the new energy vehicle sector.

The development of graphene has elevated graphite’s applications to a new level. The production of high-quality graphene often starts with the exfoliation of graphite into fine powders. Here, jet mill pulverization plays a pivotal role as a physical method to pre-treat natural graphite, creating the ideal feedstock for subsequent efficient graphene preparation processes. This controlled size reduction is a critical step in ensuring the quality and performance of the final graphene material used in supercapacitors and foldable displays.

3. Fluorspar

Fluorspar, also known as fluorite, has calcium fluoride (CaF2) as its main component. It is a world-class scarce resource similar to rare earth elements. Fluorspar is a fluorine raw material, and fluorine-containing materials are among the new chemical materials. Fluorochemical products have high performance and added value, earning a reputation as a golden industry and moving toward being a rare resource. Its products and materials are widely used in industrial sectors and daily life, as well as in strategic emerging industries such as new energy, biology, energy conservation, and environmental protection.

(1) Applications of Fluorspar in Strategic Emerging Industries

In the new energy sector, fluorine-containing backsheet and front films enhance solar panels, while specialized fluorocarbon coatings protect wind turbine blades. Lithium hexafluorophosphate serves as a key electrolyte in lithium batteries, and perfluorinated ion-exchange membranes are crucial components in fuel cells. For new energy vehicles, fluorine-based materials improve power lithium batteries and provide reliable sealing. The new-generation IT industry utilizes fluorinated liquid crystals and electronic chemicals in flat-panel displays, semiconductors, and communication cables. In biology, novel fluorine intermediates and efficient fluorination reagents enable the production of advanced pharmaceuticals. Environmental protection relies on PVDF hollow fiber membranes for wastewater treatment and PTFE filter membranes for pollutant removal. Fluorocarbon coatings and perfluoroether vacuum greases also play an important role in construction and energy-efficient Low-E glass. Furthermore, fluorosilicone adhesives provide durable seals in automotive engines, and other high-performance fluoromaterials often appear in the automotive, aerospace, and photovoltaic industries production process.

(2) Current Status and Future Development Trends of the Fluorspar Industry

Fluorspar is a strategic mineral in China. In 2019, China achieved four global firsts in fluorspar: largest producer, largest consumer, and top producer of both basic fluorochemicals and hydrofluoric acid. While holding market advantages, China’s role remains largely that of a basic fluorochemical supplier. As downstream industries develop further, fluorspar consumption will grow at about 3.0% annually from 2019 to 2030, reaching 5.679 million tons by 2030.

The recommendations for China’s fluorochemical industry include strengthening technological research for high-end products. In processing fluorite ore into the fine powders required for chemical reactions, jet mill pulverization offers significant advantages. Its ability to produce ultra-fine fluorite powder with minimal contamination and precise particle control directly enhances the efficiency and yield of subsequent hydrofluoric acid production, forming the material basis for a strong and advanced fluorochemical industry.

4. Pyrophyllite

Pyrophyllite is a layered silicate mineral known for its chemical stability, low thermal expansion, low thermal conductivity, low electrical conductivity, high insulation, high melting point, and good corrosion resistance. It is an important raw material for functional ceramics like superhard ceramics, ultra-high voltage electroceramics, new green refractory materials, high-performance glass fibers and superhard materials (synthetic diamond). It is a significant material for new energy like wind power, turbine blades and new functional materials.

To fully leverage these properties in advanced applications, precise particle size control is essential. Jet mill pulverization technology excels in processing pyrophyllite into finely controlled powders without introducing impurities. This is crucial for manufacturing high-performance glass fibers and serving as a consistent, reliable pressure-transmitting medium in the synthetic diamond industry, where material purity and uniformity are paramount.

(1) Applications in Strategic Emerging Industries:

High-End Equipment Manufacturing: Fiberglass products using pyrophyllite as a main filler are used in military, aerospace, and body armor. Pyrophyllite coatings improve surface smoothness, whiteness, and absorption, showing broad application potential in aviation and aerospace.

New Energy: An important material for new energy (wind power, turbine blades) and new functional materials.

New-Generation Information Technology: Used for manufacturing optical glass fibers, a key material in modern communication technology.

New Materials: Production of alkali-free and medium-alkali glass balls for fiberglass. It acts as a pressure-transmitting medium in high-pressure synthesis industries like synthetic diamond. Raw material for detergents and molecular sieves.

Biology: Used as a carrier for pesticides and insecticides.

(2) Industry Status and Future Trends:

Strategic emerging industries primarily use high-quality pyrophyllite to produce high-strength glass fibers and superhard materials like synthetic diamond. The production of glass fiber relies on pyrophyllite, quartz sand, and limestone, with pyrophyllite accounting for over 50% of the content. Emerging fields such as military, aerospace, body armor, and marine engineering widely utilize these high-strength glass fiber products. Industry projections indicate a growing demand for pyrophyllite, with estimated annual growth rates of 5.0%-7.0% between 2019 and 2030. Recommendations include increasing exploration efforts to find high-quality pyrophyllite and secure future supply.

Across these four strategic non-metallic minerals, a common thread in enhancing their value is the adoption of advanced processing technologies. Investing in and applying such advanced processing methods is fundamental to strengthening the entire industrial chain.

Pó épico

As these strategic minerals continue to power emerging technologies, the demand for precise and consistent processing will only grow. At Máquinas de pó épico, we are your trusted partner in this field. We provide the advanced jet mill grinding technology necessary to meet these challenges, supporting the entire industry chain from raw material to final application.