Material karbon berpori telah mendapatkan perhatian luar biasa karena struktur dan fleksibilitasnya yang unik. Material ini dapat digunakan dalam penyimpanan energi, katalisis, filtrasi, dan adsorpsi. Untuk memanfaatkan potensinya secara maksimal, memproduksi bubuk karbon berpori ultrahalus dengan kualitas yang konsisten sangatlah penting. Penggilingan jet Keunggulannya terletak pada kemampuannya mereduksi ukuran partikel hingga skala mikron dan submikron. Kemurnian material dapat dipertahankan. Artikel ini bertujuan untuk mengeksplorasi sifat karbon berpori, menjelaskan mengapa penggilingan ultrafine diperlukan. Artikel ini juga menjelaskan mengapa penggilingan jet sangat cocok untuk karbon berpori. Lebih lanjut, artikel ini menyoroti faktor-faktor penting yang perlu dipertimbangkan saat menggiling karbon berpori, serta membahas kelebihan dan keterbatasan penggilingan jet.

Apa itu Karbon Berpori?

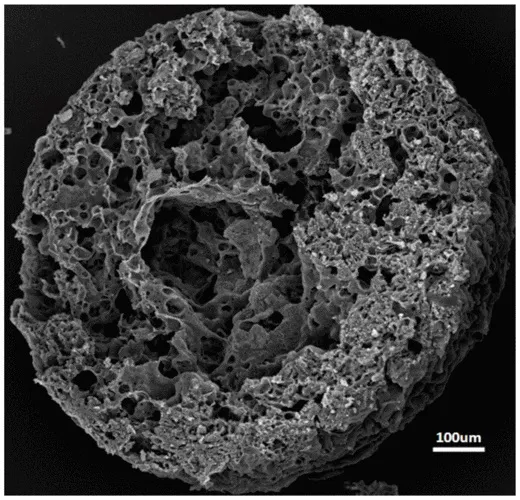

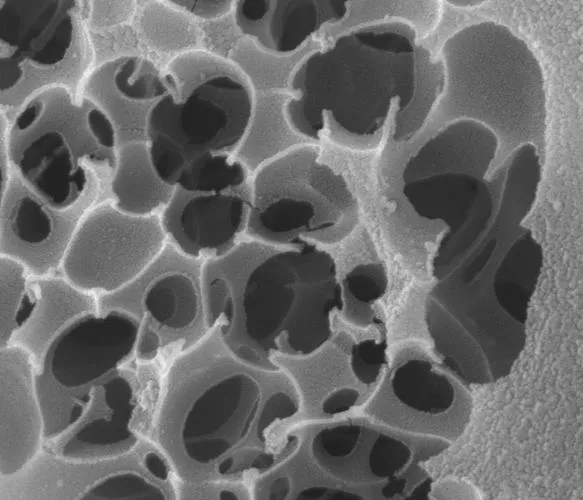

Karbon berpori dicirikan oleh jaringan pori internal yang luas, meliputi makropori, mesopori, dan mikropori. Struktur rumit ini menghasilkan luas permukaan spesifik yang sangat besar dan memberikan sifat fisik dan kimia yang unik. Fleksibilitasnya memungkinkannya untuk diaplikasikan secara luas dalam perangkat penyimpanan energi seperti baterai dan superkapasitor. Difusi ion yang cepat dan transpor elektron yang efisien sangat penting di dalamnya. Selain itu, karbon berpori berfungsi sebagai pendukung katalis karena sifat inert kimianya dan luas permukaannya yang tinggi. Dalam bidang lingkungan, karbon berpori digunakan untuk tugas pemurnian, adsorpsi, dan filtrasi karena kemampuan adsorpsinya yang sangat baik. Selain itu, sifatnya yang ringan membuatnya diinginkan dalam material komposit dan media filtrasi. Porositas membantu mengurangi densitas tanpa mengurangi kekuatan mekanis secara signifikan.

Namun, keberadaan struktur berpori seperti itu meningkatkan kompleksitas penggilingan material ini. Mempertahankan pori-pori ini sekaligus mencapai ukuran partikel yang diinginkan merupakan tantangan, tetapi penting untuk mempertahankan kinerja.

Mengapa Karbon Berpori Memerlukan Penggilingan Ultrahalus?

Penggilingan ultra-halus serbuk karbon berpori diperlukan karena beberapa alasan yang saling terkait. Pertama, mereduksi partikel menjadi ukuran yang lebih kecil sambil mempertahankan struktur pori internalnya memaksimalkan luas permukaan yang dapat diakses. Hal ini pada gilirannya meningkatkan aktivitas katalitik, kapasitas adsorpsi, dan kinerja elektrokimia. Kedua, mencapai distribusi ukuran partikel yang seragam dan halus meningkatkan dispersi dalam matriks komposit atau sistem elektrolit, memberikan konsistensi dalam perilaku mekanis, listrik, atau kimia. Lebih lanjut, pengendalian ukuran partikel memungkinkan penyesuaian aksesibilitas pori dan sifat transpor massa, yang penting untuk aplikasi seperti siklus pengisian/pengosongan cepat dalam penyimpanan energi atau adsorpsi selektif dalam sistem pemurnian. Terakhir, memproduksi serbuk ultra-halus mengurangi aglomerasi, menghasilkan keseragaman antar-batch yang lebih baik, yang penting untuk manufaktur industri berskala besar.

Terlepas dari manfaat-manfaat ini, arsitektur berpori yang halus pada material ini membuatnya rentan terhadap keruntuhan atau kerusakan jika penggilingan terlalu agresif. Oleh karena itu, metode penggilingan yang lembut namun efektif sangatlah penting.

Mengapa Penggilingan Jet Digunakan untuk Karbon Berpori?

Penggilingan jet menonjol sebagai metode penggilingan ultrahalus yang optimal untuk karbon berpori, terutama karena karakteristik operasionalnya yang unik dan selaras dengan sifat rapuh material tersebut. Mekanismenya melibatkan penggunaan gas bertekanan berkecepatan tinggi untuk mempercepat partikel sehingga mereka saling bertabrakan dalam lingkungan terfluidisasi. Interaksi partikel-ke-partikel ini menghindari kontak mekanis langsung dengan komponen penggiling. Hal ini secara efektif mengurangi kontaminasi dan tekanan mekanis yang dapat merusak pori-pori.

Lebih lanjut, jet mill beroperasi pada suhu yang relatif rendah karena ekspansi adiabatik gas terkompresi menciptakan efek pendinginan. Kontrol suhu ini biasanya menjaga ruang milling di bawah 60°C, mengurangi risiko oksidasi atau degradasi termal — pertimbangan penting untuk material karbon yang diketahui sensitif terhadap termal.

Teknologi ini juga memungkinkan kontrol presisi ukuran partikel melalui parameter yang dapat disesuaikan seperti tekanan gas, laju umpan, dan kecepatan pengklasifikasi (jika dilengkapi). Penyesuaian ini memastikan produksi bubuk ultrahalus yang konsisten dengan distribusi ukuran partikel yang sempit dan disesuaikan dengan kebutuhan aplikasi tingkat lanjut. Selain itu, pengoperasian dalam sistem loop tertutup yang tertutup rapat mengurangi paparan kelembapan atau kontaminan atmosfer, sehingga menjaga integritas bubuk karbon berpori yang rentan menyerap uap air.

Kemampuan beradaptasi terhadap material yang rapuh dan mudah pecah merupakan alasan lain mengapa Jet milling unggul di sini, karena tumbukan partikel yang halus mempertahankan arsitektur pori sekaligus memungkinkan pengurangan ukuran partikel. Terakhir, skalabilitas dan kemampuannya untuk operasi berkelanjutan berkisar dari batch skala laboratorium hingga volume industri, menawarkan fleksibilitas dan efisiensi tinggi bagi produsen.

Pertimbangan Penting Saat Menggunakan Jet Milling untuk Karbon Berpori

Untuk mencapai hasil penggilingan yang optimal dan menjaga kualitas material, beberapa faktor penting harus dikelola dengan hati-hati selama penggilingan Jet karbon berpori.

Pertama, optimalisasi parameter penggilingan perlu diperhatikan. Tekanan gas secara langsung memengaruhi kecepatan partikel. Tekanan yang lebih tinggi umumnya menghasilkan partikel yang lebih halus. Namun, tekanan yang berlebihan dapat menyebabkan penggilingan berlebih atau fraktur partikel, sehingga mengganggu integritas struktur pori. Demikian pula, laju umpan memerlukan penyeimbangan untuk menjaga konsistensi throughput material dan penggilingan yang seragam. Mengumpankan material terlalu banyak mengurangi waktu tinggal, menghasilkan partikel yang lebih kasar dan tidak rata, sementara mengumpankan material terlalu sedikit mengurangi throughput dan berisiko penggilingan berlebih. Jika Jet mill dilengkapi dengan classifier, pengaturan kecepatan roda classifier akan menyempurnakan batas ukuran, memungkinkan kontrol distribusi ukuran partikel yang presisi dan menghindari partikel halus atau fraksi kasar yang tidak diinginkan.

Kedua, menjaga integritas pori sangatlah penting. Karena struktur tiga dimensi karbon berpori sangat rapuh, operator harus menghindari gaya penggilingan yang kuat atau waktu tinggal yang lama yang dapat merusak pori-pori. Membatasi dampak mekanis yang berlebihan dan mempertahankan intensitas penggilingan yang moderat membantu menjaga arsitektur internal material. Selain itu, mencegah lonjakan suhu selama penggilingan akan mencegah perubahan kimia permukaan atau degradasi dinding pori.

Ketiga, pengendalian kontaminasi sangat penting untuk aplikasi yang mengutamakan kemurnian. Komponen peralatan yang bersentuhan dengan produk harus memiliki lapisan inert yang tahan aus—seperti lapisan keramik atau silikon karbida—untuk mencegah kontaminasi logam. Pembersihan menyeluruh antar batch juga mengurangi risiko kontaminasi silang. Selain itu, udara atau gas bertekanan yang digunakan harus bebas dari minyak, kelembapan, atau partikulat untuk menjaga kualitas produk.

Keempat, pengendalian kadar air menjadi perhatian utama karena karbon berpori cenderung higroskopis. Penggunaan udara bertekanan kering bebas minyak dan pengoperasian dalam sistem tertutup meminimalkan penyerapan air selama penggilingan. Penyimpanan pasca-penggilingan yang tepat dalam lingkungan yang terkendali akan semakin menjamin stabilitas produk.

Kelima, perawatan peralatan secara berkala, terutama komponen yang aus seperti nozel dan liner, sangat penting untuk menjaga efisiensi penggilingan dan konsistensi produk. Analisis ukuran partikel rutin dapat memberikan umpan balik untuk penyesuaian proses guna mempertahankan spesifikasi yang diinginkan.

Terakhir, tindakan pencegahan keselamatan tidak boleh diabaikan. Serbuk karbon berpori halus dapat menimbulkan bahaya ledakan debu. Sistem pengumpulan debu, ventilasi, dan mitigasi ledakan yang efektif harus tersedia untuk melindungi pekerja dan fasilitas.

Keuntungan dan Kerugian Jet Milling untuk Karbon Berpori

Penggilingan jet menawarkan keuntungan signifikan, termasuk produksi bubuk dengan kemurnian tinggi karena minimnya kontak mekanis sehingga meminimalkan kontaminasi. Rendahnya panas yang dihasilkan mempertahankan sifat fisik dan kimia karbon berpori. Kontrol ukuran partikel yang presisi, kemampuan operasi berkelanjutan, dan skalabilitas memfasilitasi produksi bubuk ultrahalus yang terdistribusi secara konsisten dan sempit. Selain itu, sistem tertutup meningkatkan keamanan lingkungan dan produk, sementara desain mekanis yang relatif sederhana mengurangi kerumitan perawatan.

Di sisi lain, penggilingan jet dapat lebih boros energi dibandingkan dengan beberapa penggilingan mekanis, terutama ketika menargetkan partikel yang sangat halus. Keausan pada nosel berkecepatan tinggi dan lapisan internal mengakibatkan biaya penggantian berkala. Pembatasan ukuran umpan seringkali memerlukan pra-pemrosesan awal seperti penghancuran atau penyaringan untuk memastikan penggilingan yang efisien. Tanpa kontrol parameter yang cermat, penggilingan berlebih dan kerusakan selanjutnya pada struktur pori dapat terjadi. Selain itu, investasi modal untuk sistem penggilingan jet berkualitas tinggi dan peralatan kompresi udara terkait relatif tinggi.

Efek yang Dicapai Menggunakan Jet Mill EPIC untuk Penggilingan Karbon Berpori

Bubuk EPIK Jet mill canggih dari Machinery menggabungkan inovasi desain yang dirancang khusus untuk penggilingan ultrafine karbon berpori. Sistem kami menawarkan penyesuaian parameter yang presisi, memungkinkan operator mengoptimalkan tekanan gas, laju umpan, dan pengaturan pengklasifikasi untuk menyeimbangkan intensitas penggilingan dengan pelestarian struktur pori. Kami menggunakan lapisan keramik dan silikon karbida berdaya tahan tinggi untuk komponen aus, yang secara efektif memperpanjang masa pakai sekaligus menjaga kemurnian produk dan meminimalkan waktu henti. Pendinginan yang efisien melalui ekspansi gas memastikan suhu penggilingan tetap rendah, melindungi arsitektur berpori yang rapuh dan kimia permukaan.

Jet mill kami beroperasi dalam konfigurasi loop tertutup dengan sistem pengumpul debu terintegrasi, yang secara signifikan mengurangi kontaminasi dan emisi lingkungan. Hal ini memungkinkan produksi bubuk karbon berpori ultrahalus yang konsisten, mencapai nilai D50 dalam rentang mikron rendah hingga submikron, dengan distribusi ukuran partikel yang sempit dan dapat direproduksi. Selain itu, desainnya yang kokoh namun mudah dirawat mendukung operasi yang berkelanjutan dan terukur—dari skala pilot hingga skala industri penuh—yang membantu produsen meningkatkan kinerja bubuk sekaligus mengoptimalkan efisiensi operasional.

Kesimpulan

Karbon berpori membutuhkan pendekatan penggilingan ultra-halus khusus yang secara cermat menyeimbangkan pengurangan ukuran partikel secara menyeluruh dengan pelestarian struktur pori-pori vital. Penggilingan jet memenuhi kebutuhan ini dengan sempurna dengan menggabungkan penggilingan energi fluida, kontrol ukuran partikel yang presisi, beban termal rendah, kontaminasi minimal, dan operasi berkelanjutan yang terukur. Operator yang mengoptimalkan kondisi penggilingan dengan cermat akan menjaga integritas peralatan. Selain itu, penerapan kontrol kontaminasi dan kelembapan akan memaksimalkan sifat-sifat menguntungkan dari bubuk karbon berpori ultra-halus untuk aplikasi teknologi canggih.

Kota Qingdao Perusahaan Mesin Serbuk EPICEPIC bangga menghadirkan solusi Jet milling terdepan di industri yang dirancang dengan spesifikasi yang tepat. Didukung oleh keahlian teknis yang mendalam dan dukungan pelanggan yang andal, peralatan kami memungkinkan produsen untuk mewujudkan produk karbon berpori yang unggul dengan kualitas dan efisiensi yang konsisten. Untuk konsultasi ahli atau pertanyaan tentang solusi Jet milling EPIC untuk karbon berpori, silakan hubungi tim profesional kami. Bersama-sama, kita dapat mendorong produksi Anda menuju keunggulan dengan teknologi mutakhir dan layanan tepercaya.