Titanium suboxide, often referred to as titanium black, is an inorganic functional material characterized by its blue-black, free-flowing powder form. It is non-toxic, exhibits excellent thermal stability, high hydrogen and oxygen evolution overpotential. Its outstanding properties including corrosion resistance, wear resistance, superior electrical conductivity, and remarkable chemical stability. These attributes make it highly valuable across industries such as electrocatalytic oxidation for wastewater treatment, marine anti-corrosion, and as a conductive additive. fresado por chorro, also known as air jet milling or fluid energy milling, is the preferred technique for pulverizing titanium suboxide.

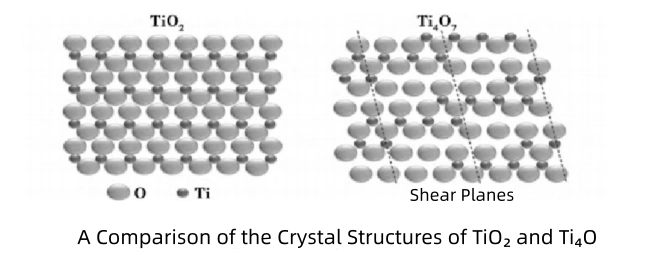

The exceptional properties of Magnéli phase titanium suboxides stem from their unique crystal structure. It can be visualized as a network of TiO₂ octahedra, but with a key difference: periodic oxygen deficiencies. For instance, in Ti₄O₇, after every few layers of TiO₂, a layer with oxygen vacancies forms. It creates a crystallographic shear plane. Within these oxygen-deficient layers, titanium atoms are closer together, forming conductive chains or bands. Crucially, these conductive pathways are shielded by the stable TiO₂ layers on either side, which grants materials like Ti₄O₇ their exceptional combination of high electrical conductivity and strong corrosion resistance.

Related parameters

| Product Name | Titanium Suboxide |

| Chemical Formula | TiₙO₂ₙ₋₁ |

| Chemical Form | Magnéli Phase Titanium Suboxide |

| Appearance | Blue-Black Powder |

| Tone L Value | < 16 |

| Ti₄O₇ Content | ≥ 95 % |

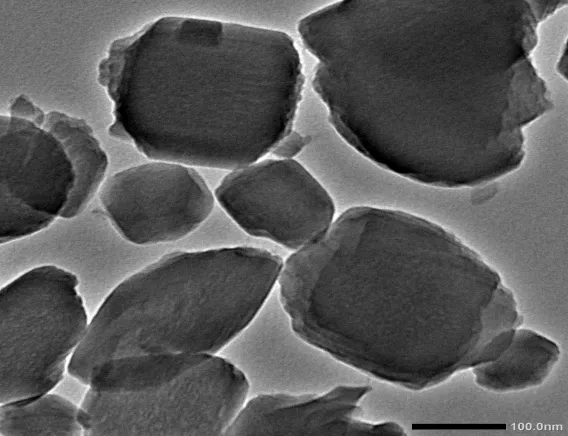

| Primary Particle Size | 0.5 ~ 1 μm |

| Particle Size & Corresponding Resistivity | < 1 μm:> 30 mΩ·m |

| 1 ~ 10 μm:30 ~ 80 mΩ·m | |

| 10 ~ 30 μm:3 ~ 5 mΩ·m | |

| 30 ~ 50 μm:< 3 mΩ·m | |

| 50 ~ 80 μm:< 3 mΩ·m | |

| Heat Resistance (in air) | < 600 °C |

| Relative Density | 3.6 ~ 4.3 |

| Water Solubles | < 0.5 g/ml |

Key Parameters & Application Fields

1. Electrode Material

Titanium suboxide offers exceptional chemical stability and corrosion resistance, outperforming most common industrial electrode materials, including its parent metal, titanium. It remains stable in highly aggressive media, such as fluoride-containing solutions and hydrochloric acid, where titanium metal would rapidly corrode. For example, it is nearly inert in 40% sulfuric or oxalic acid, which severely attack titanium metal.

| Sample | Electrolyte | Weight Loss (150 hrs) | Weight Loss (3500 hrs) |

| Titanium Metal | 1000 ppm F⁻ | 22% | 100% |

| Titanium Suboxide | 1000 ppm F⁻ | 0.017% | 0.29% |

| Titanium Metal | 4000 ppm F⁻ | 52% | 100% |

| Titanium Suboxide | 4000 ppm F⁻ | 0.66% | 2.4% |

| Titanium Metal | HF/HNO₃/H₂O 2/10/88 | 100% | 100% |

| Titanium Suboxide | HF/HNO₃/H₂O 2/10/88 | 0.56% | 12.7% |

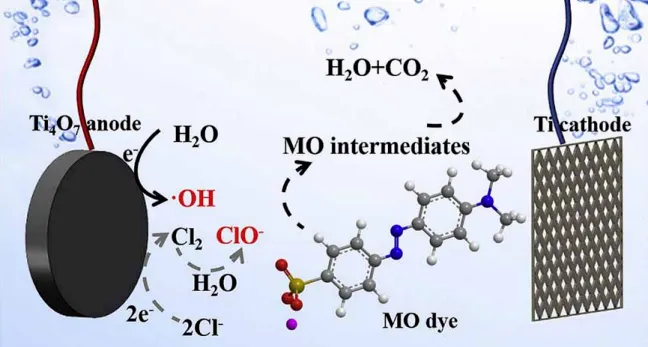

2. Electrochemical Wastewater Treatment

Due to its high oxygen evolution overpotential, titanium suboxide electrodes are ideal for anodic oxidation processes. This enables efficient electrocatalytic degradation of organic pollutants in applications including landfill leachate, phenol-containing wastewater, textile dyeing effluent, oilfield wastewater, and hospital sewage. It is also used in electrolytic hydrogen production from seawater, seawater desalination, water disinfection, and ozone generation.

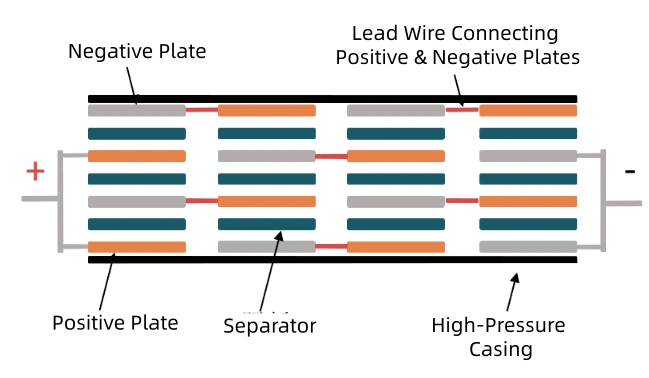

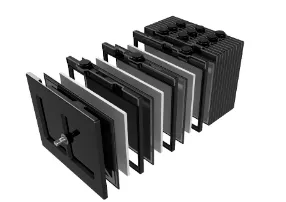

3. Advanced Lead-Acid Batteries

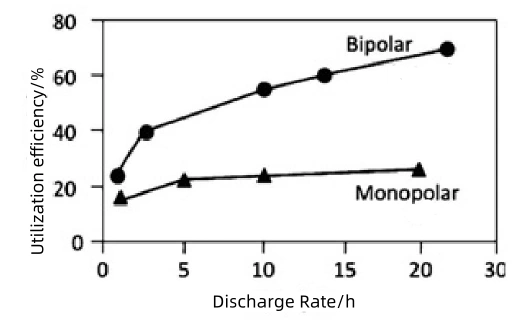

In 2012, Atraverda Ltd. commercialized a bipolar lead-acid battery utilizing titanium suboxide. These batteries are reported to be 40% lighter, 20% smaller, and offer a 40% higher energy density with over 100% longer cycle life compared to traditional lead-acid batteries. They are also more environmentally friendly, using 50% less lead and generating 80% less CO₂ during manufacturing. Furthermore, they are fully recyclable and more cost-effective than alternatives like lithium-ion batteries.

4. New Energy Batteries

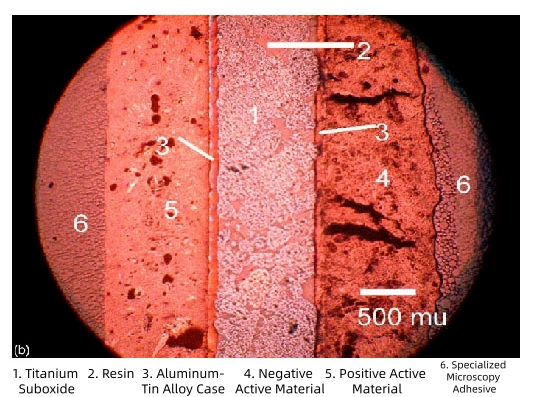

Lead-Acid: Titanium suboxide (Ti₄O₇) enhances the binding force with PbO₂ and helps maintain pore structure and porosity during charge-discharge cycles. This improves the formation efficiency and utilization of the positive active material. Adding a small amount of Ti₄O₇ fiber to automotive flat plate batteries has been shown to increase capacity by 15-17%.

Lithium-Ion: As a conductive additive in lithium-ion battery cathodes, titanium suboxide can replace traditional carbon black. It improves cathode conductivity, ensures uniform current distribution, elevates the discharge voltage platform, and boosts active material utilization. Preliminary tests indicate a 5% increase in discharge voltage and a corresponding rise in discharge energy.

5. Cathodic Protection and Anti-Corrosion Coatings

Titanium suboxide offers high conductivity (surpassing graphene in some metrics), resistance to acids/alkalis, UV absorption, high thermal stability, and good dispersibility in water and resins. Its combination of “conductivity + inertness” makes it ideal for long-term protection in harsh environments, such as marine engineering and chemical equipment. Incorporating titanium suboxide particles into anti-corrosion coatings (e.g., epoxy, polyurethane) promotes uniform charge distribution, preventing localized galvanic corrosion. Studies show that coatings modified with titanium suboxide establish cathodic protection faster and maintain it for longer durations compared to those with traditional inert fillers.

6. Advanced Pigments

The high conductivity of Magnéli phase titanium suboxides enables their use in anti-static and conductive pigments for coatings and inks. They can replace carbon black to achieve deep black, conductive coatings with superior weatherability. Furthermore, their crystal structure strongly absorbs visible light, yielding a deep gray to black color. They are more heat-resistant than carbon black (suitable for ceramics and high-temperature coatings) and are non-toxic, offering a potential replacement for hazardous cobalt or chromium-based black pigments. Composite pigments with TiO₂ can also be engineered to control photocatalytic activity, reducing UV degradation and enhancing coating durability and anti-fouling properties. By controlling particle morphology and size, special effects like metallic luster can be achieved for automotive and decorative coatings.

Optimizing Performance with Advanced Processing

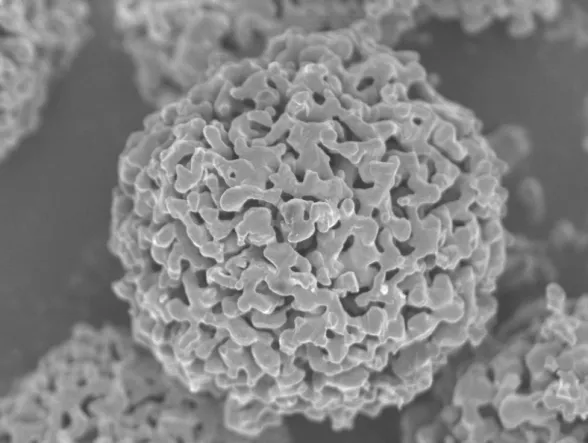

The exceptional functional properties of titanium suboxide are highly dependent on its powder characteristics, including purity, particle size distribution, and morphology. To achieve the highest performance levels, contamination during processing must be avoided. Jet milling, also known as air jet milling or fluid energy milling, is the preferred technique for pulverizing titanium suboxide. This method utilizes high-speed jets of compressed air or gas to achieve ultra-fine air crushing and classification without any mechanical moving parts contacting the material. The airflow grindingprocess ensures:

Absolute Purity: No metal contamination from grinding media.

Thermal Protection: Low-temperature jet pulverization prevents phase changes or oxidation.

Superior Powder Quality: Produces spherical particles with a narrow size distribution, ideal for electrode fabrication, coatings, and composite materials.

Titanium suboxide (Ti₄O₇), with its unique Magnéli phase structure and high conductivity, demonstrates excellent performance in batteries, environmental protection, and corrosion prevention. It serves as a core material for lighter, more efficient bipolar lead-acid batteries, a powerful electrocatalyst for degrading stubborn wastewater pollutants, and a durable, conductive component for long-lasting anti-corrosion systems.

Polvo épico

Polvo épico provides tailored-made fresado por chorro solutions for industries seeking to leverage the full potential of advanced materials like titanium suboxide. Our equipment is engineered to deliver the contamination-free, low-temperature air grinding essential for producing high-purity, functional powders. If your application demands the superior performance of precisely processed materials, Contacta con Epic Powder to discover how our jet pulverization expertise can enhance your product’s performance and reliability.