Air jet mills have become a cornerstone in the processing of fine powders, especially for versatile materials like calcium carbonate. Widely used in industries ranging from plastics and paints to pharmaceuticals and food, calcium carbonate requires precise particle size control to ensure optimal performance in end products. Selecting the appropriate molino de chorro is critical for achieving efficiency, cost-effectiveness, and consistent quality. This guide provides a step-by-step approach to choosing the ideal air jet mill for calcium carbonate, backed by technical insights and practical recommendations.

1. Understand Calcium Carbonate’s Material Properties

Calcium carbonate exhibits distinct characteristics that influence mill selection. With a Mohs hardness of around 3, it is relatively soft but requires careful handling to avoid contamination or thermal degradation. Key considerations include:

Purity Requirements: Industries like pharmaceuticals demand high purity. Jet mills that rely on self-collision grinding (e.g., fluidized bed or flat-disc models) prevent contamination by avoiding metal-to-material contact.

Thermal Sensitivity: Calcium carbonate can degrade under excessive heat. Jet mills operating at near-ambient temperatures (10°C–20°C) are ideal, as they use expanding gases for cooling during grinding.

Moisture Content: Materials with moisture levels below 15% are suitable for dry jet milling. For higher moisture, pre-drying systems may be necessary.

2. Define Your Particle Size and Distribution Goals

Jet mills excel in producing fine to ultra-fine powders. For calcium carbonate used in plastics or coatings, a d97 ≤ 5µm is often required. Key factors include:

Adjustable Classification: Models with integrated turbo classifiers allow precise control, enabling outputs from 3–100 microns.

Narrow Particle Distribution: Applications like pharmaceutical fillers need uniform granules. Fluidized bed jet mills achieve tight distributions by using multiple nozzles to enhance collision efficiency.

3. Evaluate Production Capacity and Throughput

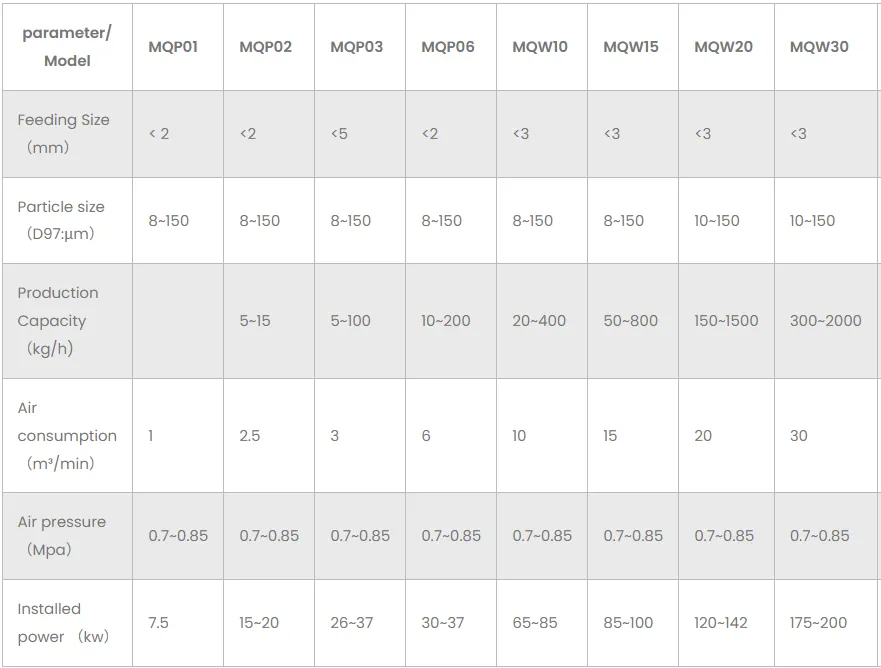

Throughput requirements directly impact mill selection. Smaller R&D units handle 0.1–0.5 kg/h, while industrial systems process up to 4000 kg/h. Consider:

Scalability: Systems like the MQW series offer 10–4500 kg/h throughput, suitable for mid-scale production.

Batch vs. Continuous Processing: Spiral jet mills (e.g., MQP series) are ideal for small-batch versatility, whereas fluidized bed models support continuous high-volume operations.

4. Prioritize Energy and Operational Costs

Jet mills can be energy-intensive, but modern designs optimize efficiency:

Air Consumption: Mid-range models use 60 m³/min of compressed air at pressures of 0.7–1.0 MPa. Energy-saving features like circulating gas systems reduce inert gas consumption for sensitive materials.

Power Usage: A typical system requires 110–132 kW for the rotor and classifier. Look for variable frequency drives (VFDs) to adjust power based on load.

5. Assess Maintenance and Safety Features

Minimizing downtime is crucial for profitability:

Wear Resistance: Mills with no internal bearings or screws reduce failure risks, extending lifespan to 2–5 years for calcium carbonate.

Automation: PLC controls enable automated adjustments and monitoring, enhancing reproducibility and safety.

Containment: Fully enclosed systems with pulse dust collectors meet environmental standards by minimizing particulate release.

6. Compare Leading Air Jet Mill Types for Calcium Carbonate

Different mill designs offer unique advantages. The table below summarizes key options:

| Mill Type | Feed Size Suitability | Particle Control | Oxidation Prevention | Best For |

| Molino de chorro en espiral | Small | Moderate | Basic | Ultrafine small batches |

| Fluidized Bed Opposed Jet | Medium to Large | High | Advanced (Closed-loop) | High-purity, large scale |

| Target/Orbital Mill | Small to Medium | Precise | Moderate | Pilot-scale, precise control |

7. Top Manufacturer Recommendations

Reputable suppliers provide tested solutions for calcium carbonate:

MQW Series: Fluidized bed jet mills with high precision classification and throughputs up to 4000 kg/h.

MQP Series: Spiral mills are suitable for pulverizing heat-sensitive, low-melting-point, sugary, and volatile materials.

Conclusión

Selecting the right air jet mill for calcium carbonate involves balancing material properties, production goals, and operational costs. Key trends in 2025 include energy-efficient designs, smart automation, and modular systems for flexibility. By prioritizing precision, scalability, and manufacturer support, businesses can invest in equipment that delivers consistent, high-quality powder while minimizing long-term expenses.

For tailored solutions, request material testing from suppliers like Polvo épico to validate performance with your specific calcium carbonate sample.

“Thanks for reading. I hope my article helps. Please leave a comment down below. You may also contact EPIC Powder online customer representative for any further inquiries.”

— Jason Wong, Senior Engineer