Der Scheibenstrahlmühle, also known as a Spiralstrahlmühle or Flat Jet Mill, is a cornerstone of ultrafine powder processing. Its design primarily consists of a material feeder, a material accelerator, a material disperser, an air manifold, nozzles, and the grinding chamber.

The process begins when the accelerator injects material into the grinding chamber, and the disperser disperses it. High-pressure gas then carries this dispersed material deeper into the chamber, where it intersects with other high-pressure streams that the nozzles eject. This powerful convergence forces the particles to collide with each other, resulting in effective pulverization through inter-particle impact, shear, and friction.

As the gas and material mixture rotates at high speeds, it generates intense centrifugal force. This force propels coarser particles back toward the grinding zone for repeated milling cycles. Finely ground powder exits through the central discharge outlet.

Disc Jet Mill: Key Advantages

1. Ultrafine Grinding

Ideal for the dry superfine grinding of powdered materials. With impact velocities capable of exceeding Mach 2.5, it can easily reduce most materials to a fine powder between 1-10 microns.

2. Wear-Resistant & High Purity

The grinding principle relies solely on particle-to-particle impact (self-attrition), making it perfect for hard, high-purity, and high-value materials. This ensures minimal contamination and preserves product integrity.

3. Effective for Sticky Materials

The design prevents clogging, ensuring consistent performance even with adhesive substances.

4. No-Temperature Rise

The adiabatic expansion of compressed gas at the nozzles causes cooling. With no mechanical moving parts generating heat, it is exceptionally suited for heat-sensitive and low-melting-point materials.

5. Inert Grinding Capability

For flammable, explosive, or oxidizable materials, the mill can operate with inert gases in a closed circuit, which are recycled with minimal loss.

6. Compact & Easy Cleaning

Featuring a compact footprint and a crevice-free design, it eliminates the risk of material residue and simplifies cleaning, ensuring strict hygiene standards.

7. Easy Maintenance

Seamless internal welding and a thoughtful design make mechanical maintenance and part replacement straightforward.

8. Operational Benefits

The mill is known for its simple operation, easy inspection, small footprint, low noise, and vibration-free operation.

9. High-Purity Linings & Components

Critical parts like the liner and nozzles can be crafted from ceramic materials, guaranteeing zero metal contact and meeting the most stringent purity requirements.

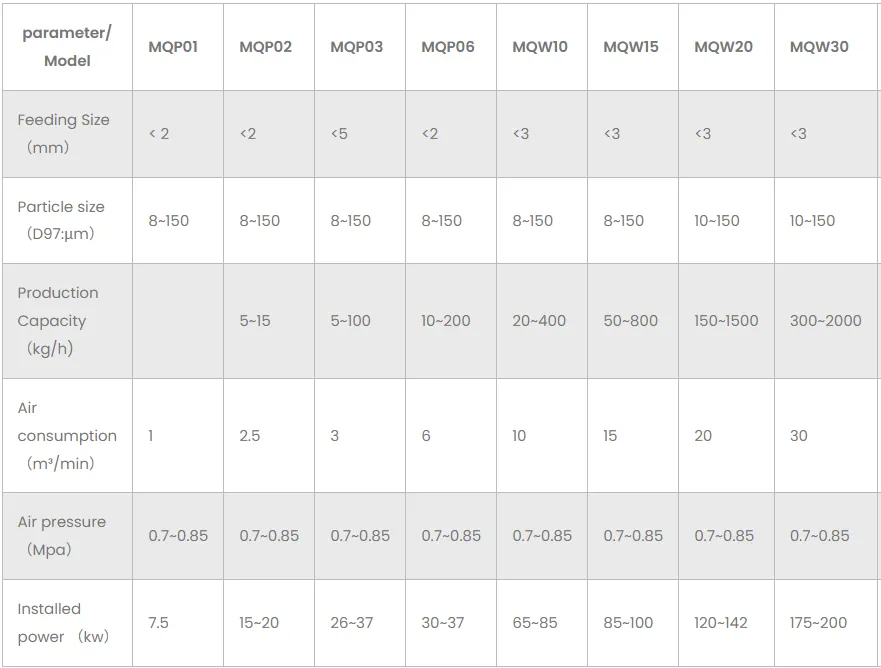

Spiral Jet Mill technical parameters

Epische Pulvermaschinen

Understanding the right technology is the first step, implementing it effectively is what sets you apart. At Epische Pulvermaschinen, we engineer Jet Mills that not only meet but exceed the rigorous demands of modern industry. Our focus is on delivering uncompromising material purity and operational efficiency. It can ensure your high-value products have absolute precision and consistency. Ready to achieve a new standard in ultrafine grinding? Contact Epische Pulvermaschinen today to discover how our milling solutions can optimize your production line.

About the Author

Senior Application Engineer @ EPIC POWDER MACHINERY

Emily Chen