Was ist Antimontrioxid?

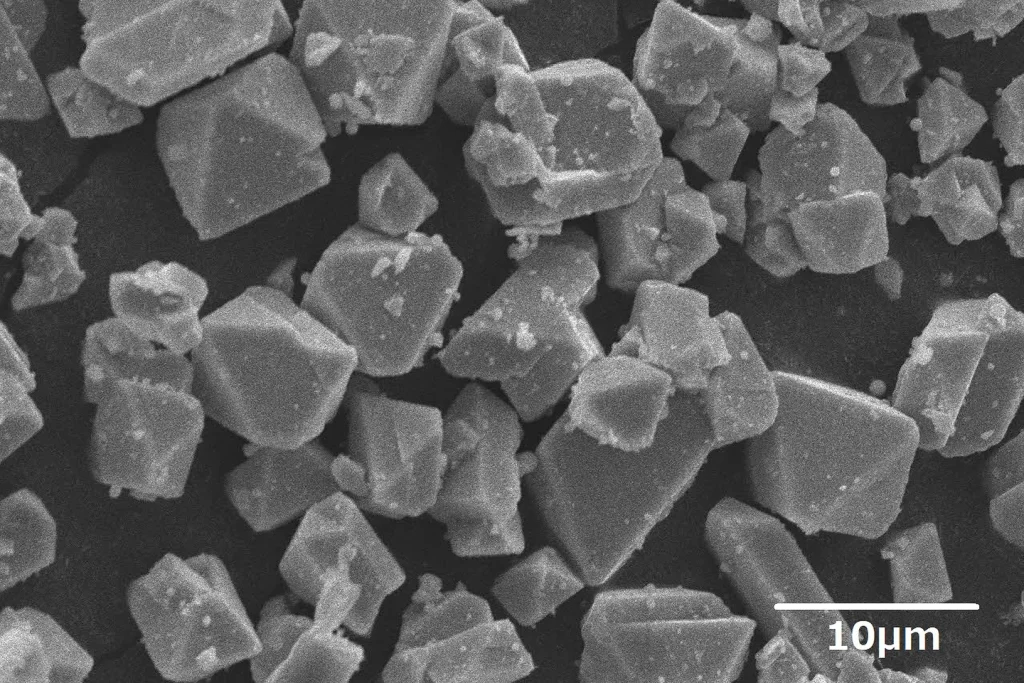

Antimontrioxid (Sb₂O₃) hat ein Molekulargewicht von 291,5, eine Dichte von 5,1 g/cm³, einen Schmelzpunkt von 656 °C und einen Siedepunkt von 1425 °C. Es kann unter Hochvakuum bei 400 °C sublimieren. Antimontrioxid ist ein weißes, kristallines Pulver, das industriell als Antimonweiß bekannt ist. Es ist schwer löslich in Wasser, verdünnter Schwefelsäure und verdünnter Salpetersäure, jedoch löslich in Salzsäure, konzentrierter Schwefelsäure, starken Laugen und Weinsäurelösungen.

Hochwertiges Antimontrioxid selbst ist wenig toxisch. Minderwertige Qualitäten können jedoch eine leichte Toxizität aufweisen, hauptsächlich aufgrund des zu hohen Arsentrioxid-Gehalts (As₂O₃). Der Kontakt kann bei Anwendern Symptome wie Juckreiz an Händen und Armen hervorrufen.

Der Klärmechanismus von Antimontrioxid ähnelt dem von Arsentrioxid. Es ist ein vielseitiges Klärmittel mit relativ hoher Dichte. Es geht bei relativ niedriger Temperatur von einem höheren Oxid zu einem niedrigeren Oxid über und eignet sich besonders gut für Gläser mit hohen Mengen an Bleioxid (PbO) oder Bariumoxid (BaO).

Die Verwendung von Antimontrioxid

Aufgrund seiner Flüchtigkeit wird Sb₂O₃ nicht allein als Klärmittel verwendet. Es wird typischerweise mit Oxidationsmitteln wie Natriumnitrat (NaNO₃) oder Kaliumnitrat (KNO₃) kombiniert.

In Kalknatronsilikatglas wird eine Kombination aus 0,18% bis 0,5% Sb₂O₃ mit der 4- bis 8-fachen Gewichtsmenge Natriumnitrat als Klärmittel verwendet. Bei niedrigeren Temperaturen reagiert es mit Sauerstoff, der bei der Zersetzung von Natriumnitrat freigesetzt wird, und bildet Antimonpentoxid (Sb₂O₅). Bei etwas höheren Temperaturen zersetzt sich Sb₂O₅ und setzt Sauerstoff frei. Dieser hochaktive Sauerstoff diffundiert in Gasblasen verschiedener Art innerhalb der Glasschmelze, wodurch sich das Volumen der Blasen ausdehnt und sie aus der Schmelze aufsteigen, wodurch die Glasklärung gefördert wird. Die chemischen Reaktionen laufen wie folgt ab:

2Sb₂O₃ + O₂ (aus NaNO₃) → 2Sb₂O₅

2Sb₂O₅ → 2Sb₂O₃ + O₂]

Wenn in Kalknatronsilikatglas 0,2% Antimontrioxid zusammen mit 0,2% Arsentrioxid (As₂O₃) verwendet wird, verstärkt sich der Kläreffekt. Dies liegt daran, dass Sb₂O₅ bei niedrigeren Temperaturen Sauerstoff freisetzt, während Arsenpentoxid (As₂O₅) bei höheren Temperaturen Sauerstoff freisetzt. Dadurch wird sichergestellt, dass das Klärmittel über den gesamten Schmelztemperaturbereich aktiv ist und die Bildung von Sekundärblasen verhindert wird. Wenn jedoch die Kombination Sb₂O₃/As₂O₃ in Bleiglas verwendet wird, können übermäßige Mengen leicht Arsenat- und Antimonatkristalle bilden, die eine Trübung des Glases verursachen.

Für die Herstellung von Solarstrukturglas müssen die chemische Zusammensetzung und die physikalischen Eigenschaften des verwendeten Antimonoxidpulvers die Anforderungen für die Güteklasse Sb₂O₃ 99,50 gemäß der chinesischen nationalen Norm GB/T 4062-2013 erfüllen oder übertreffen.

Ein wichtiger Aspekt bei der Verwendung von Antimontrioxid ist, dass Glas mit Sb₂O₃ bei Einwirkung von ultraviolettem Licht oder Sonnenlicht einen schwachen Gelbstich entwickeln kann. (Im Gegensatz dazu kann Glas mit Arsentrioxid dunkelbraun werden.)

Warum muss Antimontrioxid ultrafein gemahlen werden?

Die ultrafeine Vermahlung von Antimontrioxid ist entscheidend für die Optimierung seiner Flammschutzwirkung. Je feiner die Partikelgröße, desto größer die Oberfläche, was die Dispersion und Reaktivität in Polymer- und Textilmatrizen verbessert. Typische Qualitätsspezifikationen für Antimontrioxidpulver umfassen hohe Reinheit (~99,8%), Weiße (~96,5%) und eine durchschnittliche Partikelgröße unter 4 Mikrometern für eine effektive Anwendung. Die gleichmäßige ultrafeine Partikelgrößenverteilung verbessert die synergistische Feuerbeständigkeit in Kombination mit halogenierten Flammschutzmitteln, reduziert den Additivbedarf und verbessert Kosteneffizienz und Leistung.

Warum Luftstrahlmahlen für Antimontrioxid verwenden?

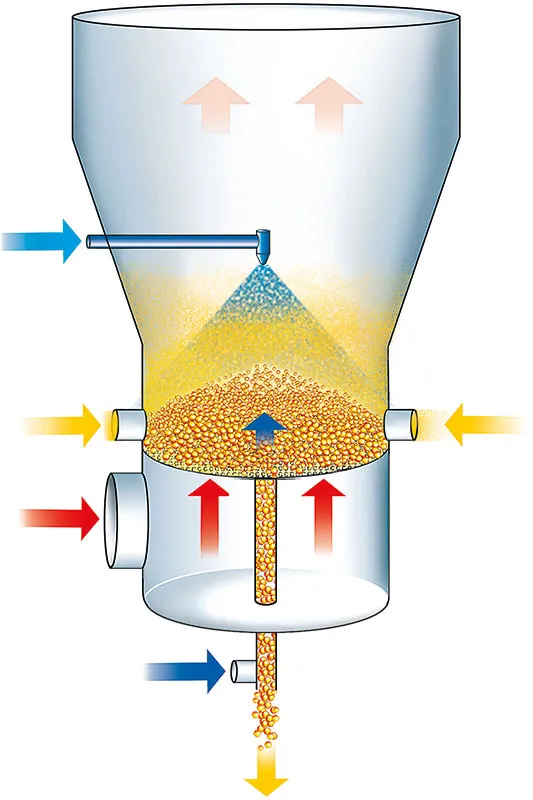

Luft Strahlfräsen (Luftstrahlmahlen) eignet sich aufgrund mehrerer technischer Vorteile besonders gut für die Antimontrioxid-Pulverisierung:

Es ermöglicht eine Trockenverarbeitung, wodurch die mit der Nassmahlung verbundenen Verunreinigungen und Umweltprobleme reduziert werden.

Das Verfahren ermöglicht das gleichzeitige Mahlen und Klassifizieren, wodurch eine präzise Partikelgrößenverteilung erreicht wird.

Luftstrahlmühlen können effizient ultrafeine Partikelgrößen erreichen, die für die typischen Anforderungen von <5 Mikron bei Flammschutzanwendungen geeignet sind.

Die Technologie erzeugt beim Pulverisieren weniger Wärme und verringert so das Risiko einer thermischen Zersetzung oder einer Veränderung der Produktchemie.

Sein geschlossenes Kreislaufsystem verbessert die Sicherheit beim Umgang mit potenziell giftigen Pulvern wie Antimontrioxidstaub.

Wichtige Überlegungen beim Luftstrahlmahlen von Antimontrioxid

Beim Mahlen von Antimontrioxid in einer Luftstrahlmühle ist auf Folgendes zu achten:

Staubkontrolle und Arbeitssicherheit: Antimontrioxid steht im Verdacht, krebserregend zu sein, daher sind wirksame Eindämmungs- und Staubabsaugsysteme von größter Bedeutung.

Kontrolle der Partikelgröße: Präzise Klassifizierereinstellungen stellen sicher, dass das Produkt den Spezifikationen entspricht, wobei in der Regel ein enger Größenbereich von etwa 2–3 Mikrometern angestrebt wird.

Qualität des Ausgangsmaterials: Konsistente Größe und Feuchtigkeitsgehalt des Ausgangsmaterials optimieren die Mahlleistung und Produktgleichmäßigkeit.

Verschleißfestigkeit: Die abrasive Natur von Mineralpulvern erfordert langlebige Mahl- und Klassifizierungskomponenten, um die Leistung aufrechtzuerhalten.

Prozessparameter: Durch die Optimierung der Luftströmungsgeschwindigkeit, der Klassifiziererdrehzahl und des Mahldrucks werden Durchsatz und ultrafeine Feinheit ausgeglichen.

EPIC Pulvermaschinen

EPIC-Pulver Maschinen Luftstrahlmühle Systeme sind so konstruiert, dass sie den anspruchsvollen Standards der Antimontrioxid-Industrie gerecht werden. Unsere Luftstrommühlen erreichen:

Partikelgrößen liegen durchgängig im Bereich von 1–3 Mikrometern mit enger Verteilung für eine hervorragende flammhemmende Synergie.

Hohe Durchsatzleistungen mit energieeffizienter Mahltechnik.

Robuste Staubkontroll- und Sicherheitssysteme gewährleisten die Einhaltung der Arbeitsschutzvorschriften.

Verschleißfeste Innenkomponenten, optimiert für abrasive Mineralpulver.

Anpassbare Prozesskontrollen ermöglichen es Kunden, Parameter für spezifische Produktanforderungen zu optimieren.

Kunden konnten durch den Einsatz der Luftstrahlmühlen von EPIC zur Herstellung von Antimontrioxidpulver eine verbesserte Produktqualität, eine geringere Additivdosierung in Endanwendungen und allgemeine Einsparungen bei den Verarbeitungskosten feststellen.